3D printing medical PLA (polylactic acid)/PCL (polycaprolactone) blend resin and preparation method thereof

A technology of polycaprolactone and three-dimensional printing, applied in the field of three-dimensional printing resin, can solve the problems of increasing difficulty in pathological analysis and difficult tissue cell engineering, and achieve good degradation rate, fast degradation rate and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

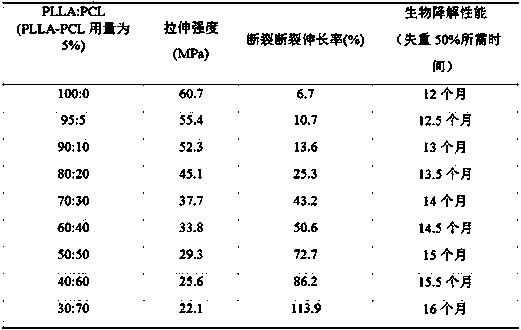

[0017] Combine L-polylactic acid (PLLA) and polyε-caprolactone (PCL) in accordance with the ratio in Table 1 with a polylactic acid / polycaprolactone diblock copolymer (PLLA-PCL) that accounts for 5% of the total mass of the two The solubilizer is mixed uniformly and pelletized in the extruder. The obtained pellets are then made into a linear material by a three-dimensional printing consumable extruder to obtain a three-dimensional printing medical PLLA / PCL blend resin.

[0018] Then the resin is printed into mechanical performance test and molding shrinkage test specimens using FDM technology for related tests. The results of the study indicate that the toughness of the resin is greatly improved, the hardness is reduced, and the biodegradation rate is slowed down, which is more conducive to the preparation of medical intervention materials such as vascular stents.

[0019] Table 1 Performance of PLLA / PCL resin when using diblock copolymer (PLLA-PCL) as a solubilizer

[0020]

Embodiment 2

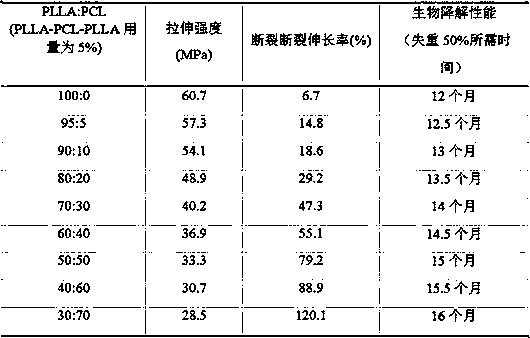

[0022] The L-polylactic acid (PLLA) and polyε-caprolactone (PCL) were combined with the polylactic acid / polycaprolactone triblock copolymer (PLLA-PCL-PCL- PLLA) The solubilizer is uniformly mixed and pelletized in an extruder; the obtained pellets are then made into a linear material by a three-dimensional printing consumable extruder to obtain a three-dimensional printing medical PLA / PCL blend resin.

[0023] Then the resin is printed into mechanical performance test and molding shrinkage test specimens using FDM technology for related tests. The results of the study indicate that the toughness of the resin is greatly improved, the hardness is reduced, and the biodegradation rate is slowed.

[0024] Table 2 Performance of PLLA / PCL resin when using diblock copolymer (PLLA-PCL) as a solubilizer

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com