Biodegradable polyester material and preparation method and application thereof, carrier material and preparation method thereof

A technology of biodegradable polyester and carrier materials, applied in pharmaceutical formulations, medical preparations with inactive ingredients, etc., can solve the problems of insufficient mechanical properties, fast degradation rate, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

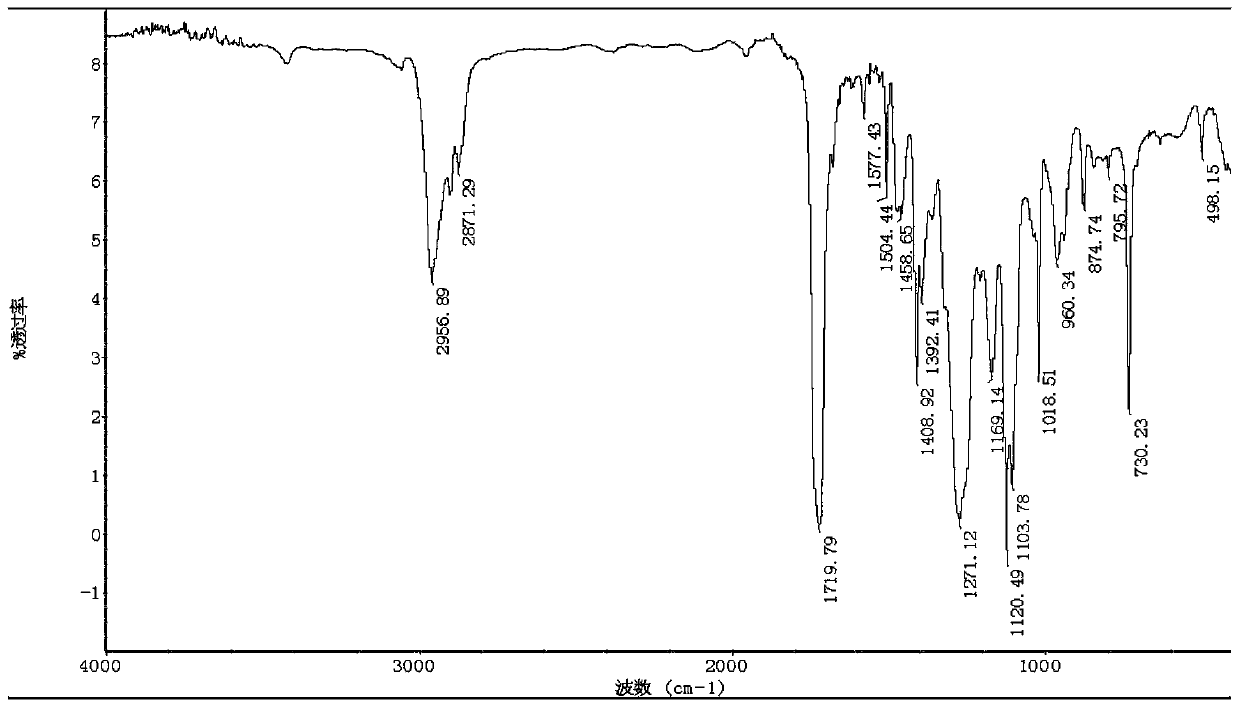

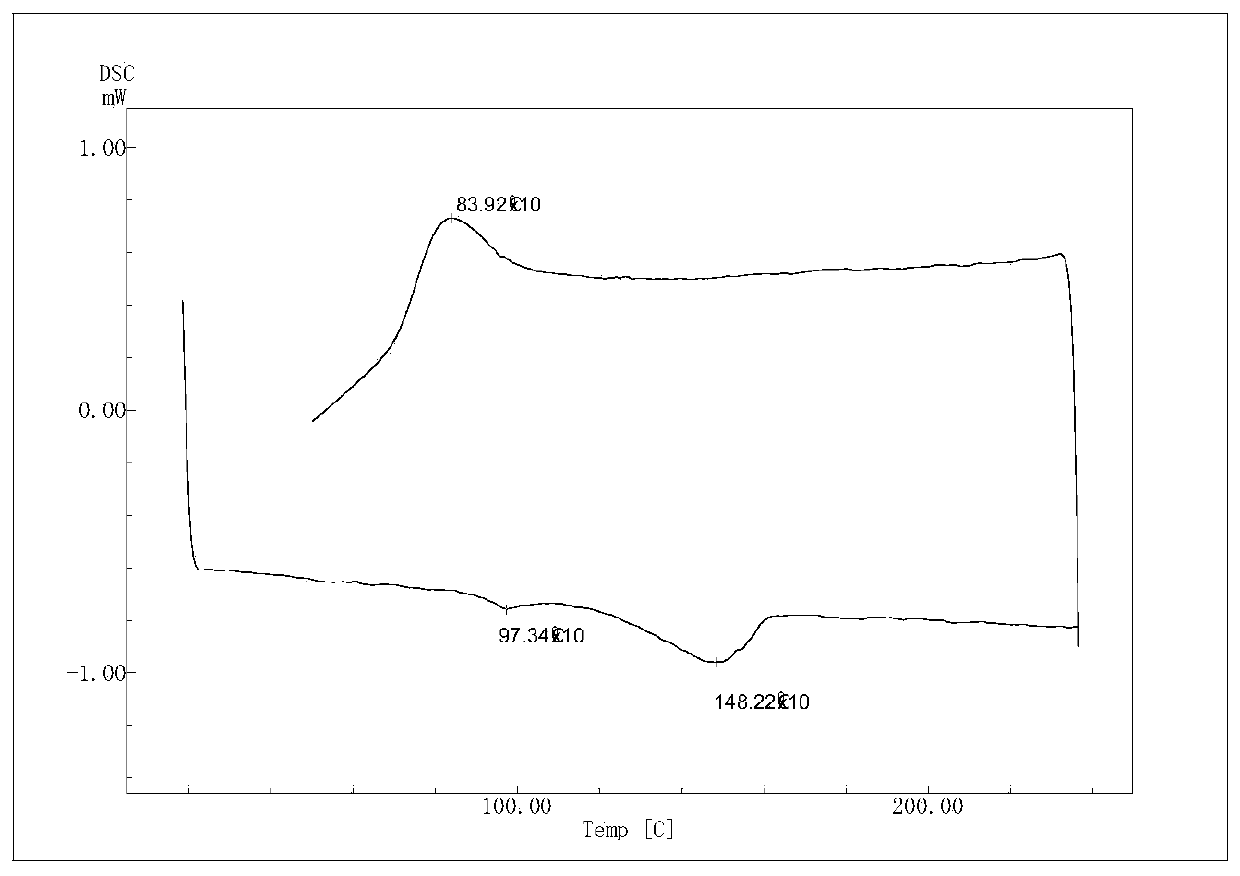

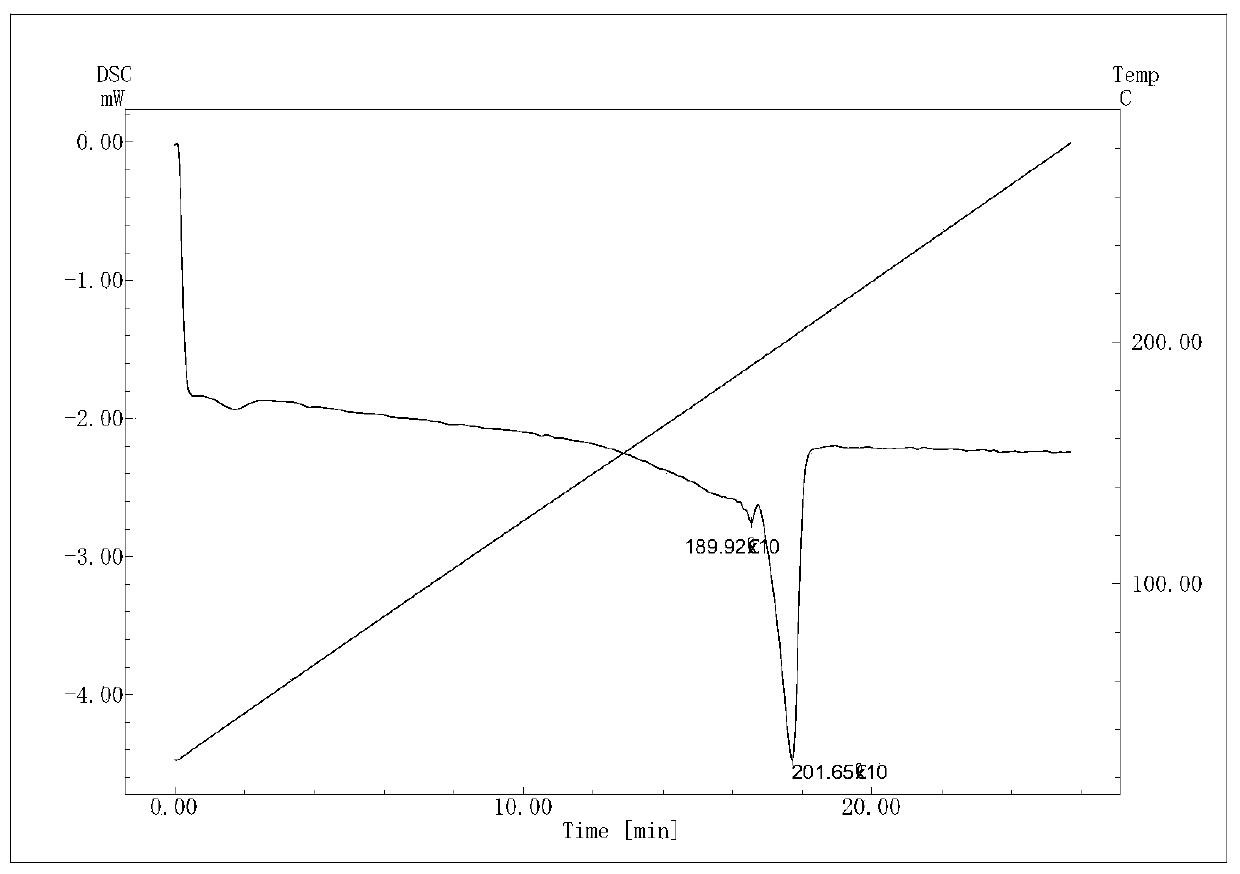

[0042] The invention provides a kind of preparation method of biodegradable polyester material, comprises the following steps:

[0043] Mix 1,4-butanediol, dimethyl terephthalate, polycaprolactone, and a transesterification catalyst to perform a transesterification reaction to obtain a transesterification product system;

[0044] The transesterification product system, chain extender, polycondensation antioxidant and polycondensation catalyst are mixed for polycondensation reaction to obtain biodegradable polyester material.

[0045] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0046]The invention mixes 1,4-butanediol, dimethyl terephthalate (DMT), polycaprolactone and a transesterification catalyst to carry out a transesterification reaction to obtain a transesterification product system. In the present invention, the molar ratio of the 1,4-butanediol, di...

Embodiment 1

[0079] The preparation process of tetrabutyl titanate-magnesium acetate-metal organic compound compound is as follows: mix 100g tetrabutyl titanate with 150mL methanol, obtain a saturated solution, reflux for 24h, evaporate half of the methanol, and convert the obtained organic titanium Product 175g is mixed with titanium powder (KRTi-4) according to mass ratio 1:1, obtains titanium catalyst; Said titanium catalyst 10g, magnesium oxide powder 15g and stannous octoate 22g are mixed, and gained mixture is mixed with ethyl acetate again according to mass Mix well at a ratio of 1:1, heat to boiling, reflux for 1 hour, add to the reaction kettle while it is hot, and carry out compounding at 85°C for 120 minutes to obtain a liquid compound, namely tetrabutyl titanate-magnesium acetate-metal organic compound compound. In this example, the mass percentage of each effective component in the tetrabutyl titanate-magnesium acetate-metal organic compound composite is calculated based on the...

Embodiment 2

[0083] The preparation process of tetrabutyl titanate-magnesium acetate-metal organic compound compound is as follows: mix 100g tetrabutyl titanate with 150mL methanol, obtain a saturated solution, reflux for 24h, evaporate half of the methanol, and convert the obtained organic titanium Product 175g is mixed with titanium powder (KRTi-4) according to mass ratio 1:1, obtains titanium catalyst; Said titanium catalyst 10g, magnesium oxide powder 7.5g and tetraphenyltin 8.1g are mixed, and gained mixture is mixed with ethyl acetate The esters are fully fused according to the mass ratio of 1:1, heated to boiling, refluxed for 1 hour, added to the reactor while hot, and compounded at 85°C for 120 minutes to obtain a liquid compound, namely tetrabutyl titanate-magnesium acetate-metal organic compound Complex. In this example, the mass percentage of each effective component in the tetrabutyl titanate-magnesium acetate-metal organic compound composite is calculated based on the mass pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com