Manufacturing method of composite material metal bone implant with structural function

A manufacturing method and composite material technology, applied in the field of medical devices, can solve the problems of matching between degradation behavior and bone reconstruction process, unreliability, and few research data on degradation behavior, so as to achieve the effect of improving bone reconstruction effect, smooth stress conduction and stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

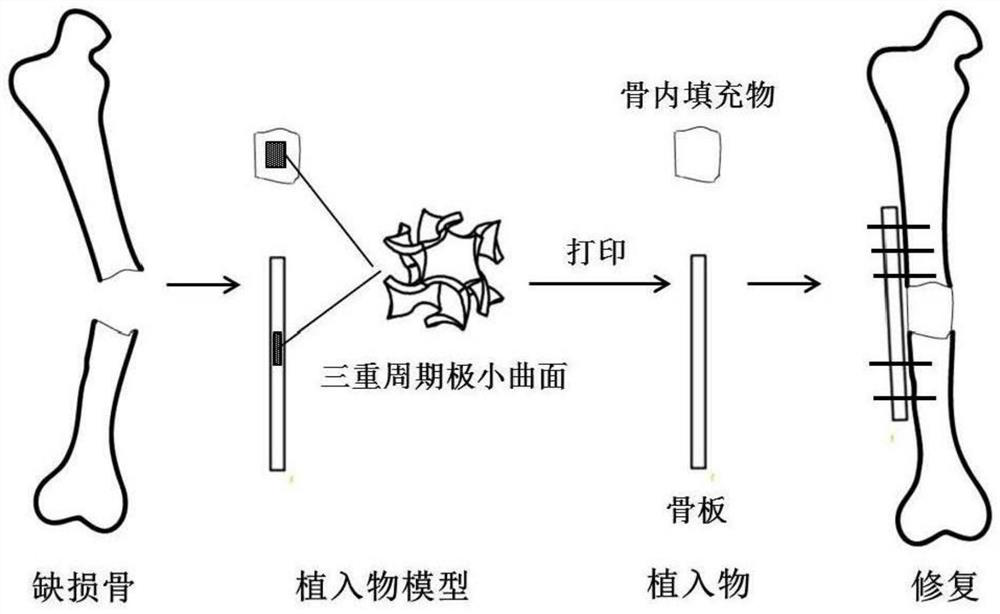

[0050] The present preferred embodiment designs and manufactures the metallic bone implant of composite material and structural function by Ti-6Al-4V-5Cu titanium alloy and Mg-5.2Zn-0.5Zr (ZK60) magnesium alloy, in order to be used for repairing femur Bone defects caused by fractures, see figure 1 . The particle size of the ZK60 magnesium alloy powder used is 15-43 μm, and the particle size of the Ti-6Al-4V-5Cu titanium alloy powder is 15-45 μm. The specific operation method is as follows:

[0051] (1) Carry out CT scanning on the patient's defect bone, and import the data into the computer to establish a three-dimensional model of the implant for repairing the bone defect;

[0052] (2) According to the physiological structure and functional requirements of the bone, the implant was divided into the functional area of the titanium alloy internal fixation bone plate and the functional area of the magnesium alloy bone filler, and the three-dimensional models of the parts in...

Embodiment 2

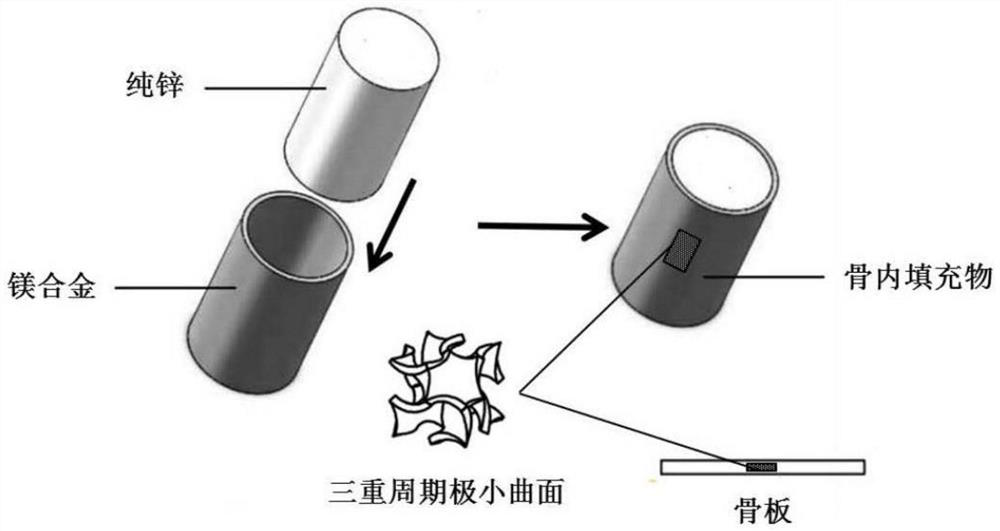

[0058] This preferred embodiment designs and manufactures the metal bone implant of composite material and structural function by Ti-6Al-4V (TC4 titanium alloy), Mg-5.2Zn-0.5Zr (ZK60 magnesium alloy) and Zn, to use For the repair of large bone defects caused by bone tumor treatment in the femur, please refer to figure 2 . The particle size of ZK60 magnesium alloy powder used is 15-43 μm, the particle size of TC4 titanium alloy powder is 14-56 μm, and the particle size of Zn powder is 15-45 μm. The specific operation method is as follows:

[0059] (1) Carry out CT scanning on the patient's defect bone, and import the data into the computer to establish a three-dimensional model of the implant for repairing the bone defect;

[0060] (2) According to the physiological structure and functional requirements of the bone, the implant was divided into titanium alloy internal fixation bone plate functional area, magnesium alloy intraosseous filling functional area and zinc alloy intr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com