Biodegradable iron-zinc-magnesium-based gradient composites based on biological bone healing and its preparation

A composite material and bone healing technology, applied in the fields of medical science, chemical instruments and methods, layered products, etc., can solve the problem of not being able to adapt to the constant changes in mechanical properties, reducing the corrosion rate of magnesium-based materials, and unable to independently meet the requirements of biological bone healing. and other problems, to achieve the effect of convenient and fast adjustment, dense and reliable combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

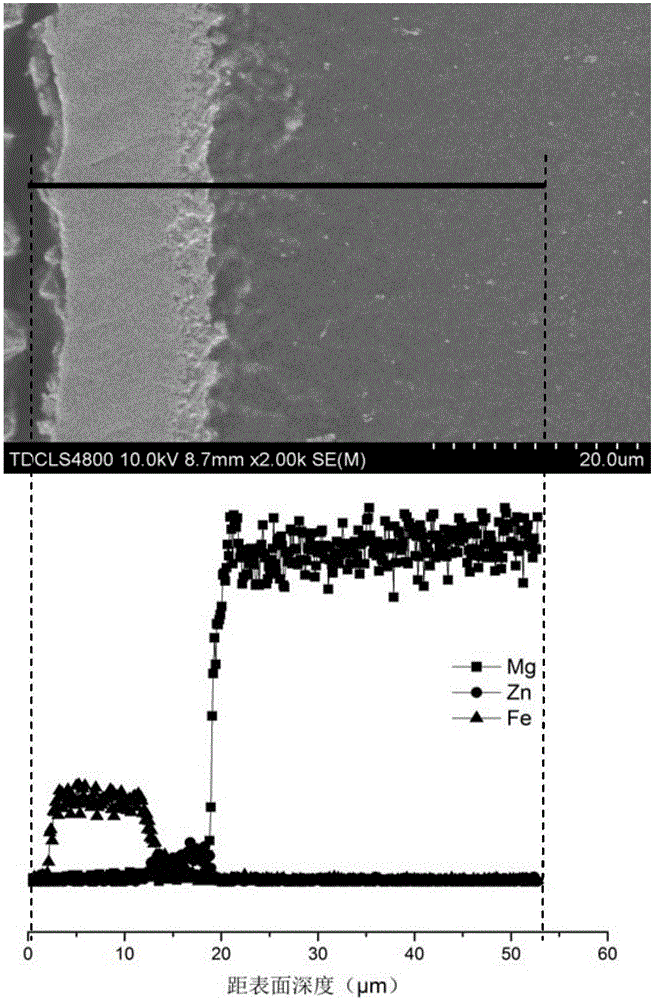

[0033] The rat model is used, and the thickness of each gradient layer of the material is designed according to the bone healing process of the rat. At the initial stage of implantation, materials with high elastic modulus and relatively slow degradation are required to ensure strong fixation, which is conducive to the growth of bone tissue. After 5 weeks, if the fixation is strong again, problems such as bone resorption caused by stress shielding effect will occur, which will affect bone tissue. heal. Therefore, after 5 weeks of rigid fixation, 3 weeks of elastic fixation is required, and a material with a lower elastic modulus is required at this time. After 8 weeks, the bone tissue is generally repaired, and the implant material needs to be rapidly degraded. Starting from the mechanical performance requirements of biological bone healing, combined with the respective advantages of iron, zinc and magnesium materials, a new type of degradable iron-zinc-magnesium-based gradie...

Embodiment 2

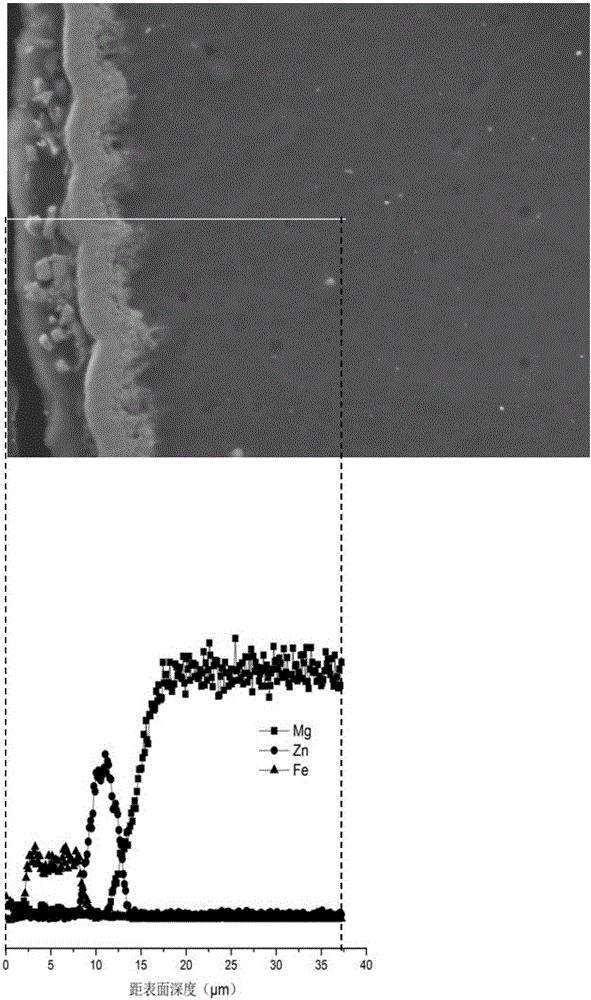

[0045] Taking the femur fracture in a 10-year-old child as an example, the thickness of each gradient layer of the material is designed according to the bone healing process of the child. At the initial stage of implantation, materials with high elastic modulus and relatively slow degradation are required to ensure strong fixation, which is conducive to the growth of bone tissue. After 3 weeks, if the fixation is strong again, problems such as bone resorption caused by stress shielding effect will occur, which will affect bone tissue. heal. Therefore, after 7 weeks of strong fixation, 3 weeks of elastic fixation is required, and a material with a lower elastic modulus is required at this time. After 7 weeks, the bone tissue is generally repaired, and the implant material needs to be rapidly degraded. Starting from the mechanical performance requirements of biological bone healing, combined with the respective advantages of iron, zinc, and magnesium materials, a new type of de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com