Fully absorbed mg-zn-ag system amorphous medical implant substrate, its preparation method and application

A fully absorbed, amorphous technology, applied in medical science, prosthesis, surgery, etc., can solve the problems of inability to form protective oxide film, fast degradation rate of magnesium and magnesium alloys, loss of function of implanted components, etc. Market application prospect, excellent mechanical strength and hardness, slow degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

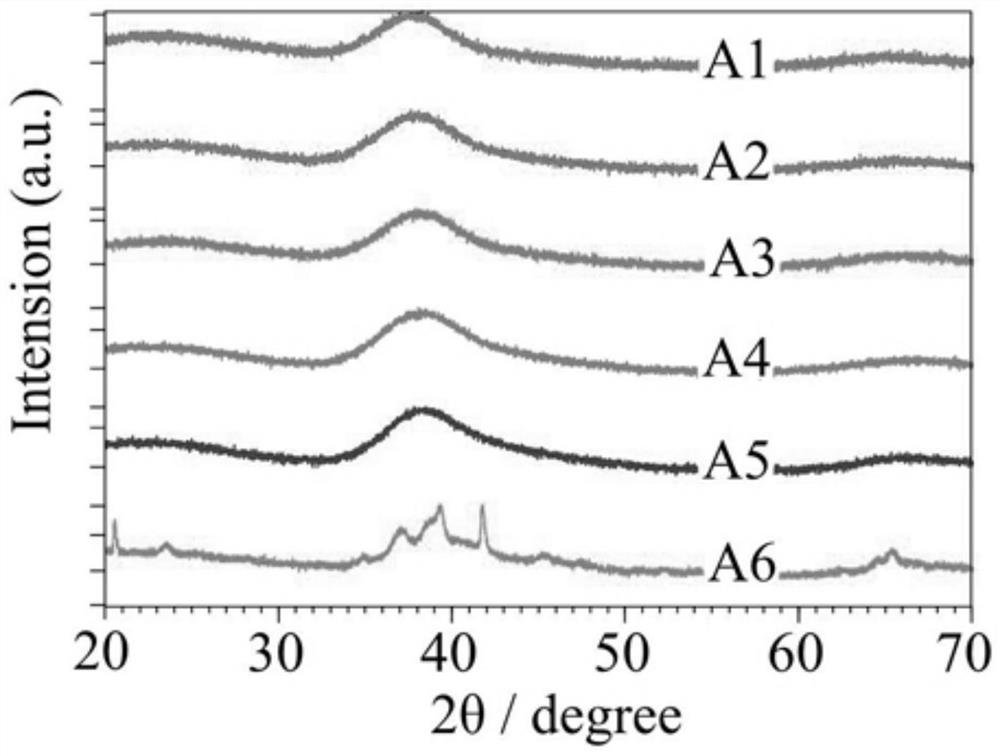

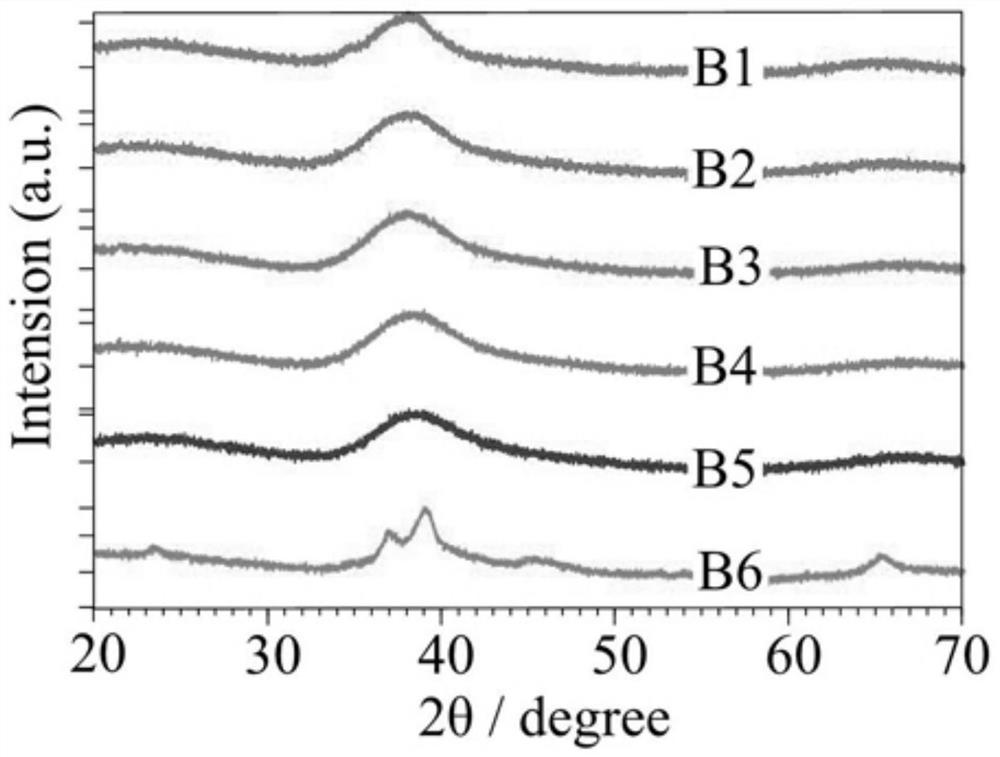

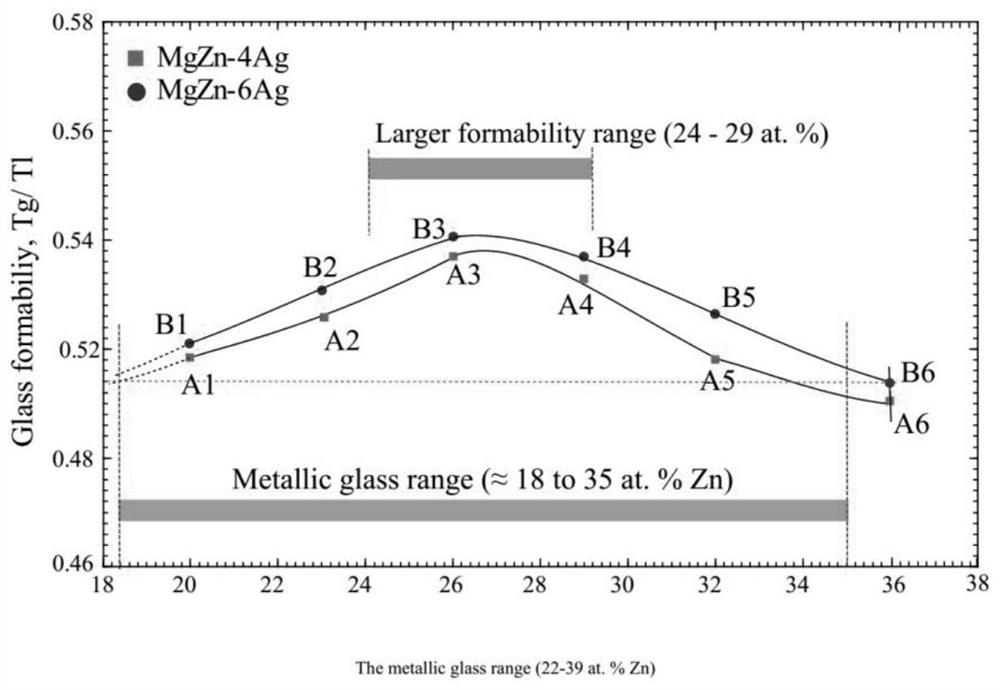

Embodiment 1

[0043] (1) According to the designed alloy composition ratio, weigh 76at.%Mg, 20at.%Zn and 4at.%Ag on an electronic balance with an accuracy of 0.0001g;

[0044] (2) put the weighed Mg, Zn, Ag raw materials into the test tube of the amorphous smelting furnace, carry out mixed smelting in the presence of high-purity inert protective gas helium, and the high-purity inert protective gas pressure is 1 standard atmospheric pressure , the input voltage of the amorphous melting furnace is three-phase 380V 50-60Hz, the maximum power is 40kW, and the working current is 300-1800A;

[0045] (3) remelting the obtained alloy at least 3 times, then feeding high-pressure inert protective gas helium into the test tube of the amorphous smelting furnace to carry out metal spray casting, and the high-pressure inert protective gas pressure is about 10Mpa;

[0046](4) demoulding after spray casting to obtain the fully absorbed Mg-Zn-Ag amorphous alloy sample A1 of the present invention: Mg76Zn20Ag...

Embodiment 2

[0049] (1) According to the designed alloy composition ratio, weigh 73at.%Mg, 23at.%Zn and 4at.%Ag on an electronic balance with an accuracy of 0.0001g;

[0050] (2) put the weighed Mg, Zn, Ag raw materials into the test tube of the amorphous smelting furnace, and carry out mixed smelting in the presence of high-purity inert protective gas argon, and the high-purity inert protective gas pressure is 1 standard atmospheric pressure , the input voltage of the amorphous melting furnace is three-phase 380V 50-60Hz, the maximum power is 40kW, and the working current is 300-1800A;

[0051] (3) remelting the obtained alloy at least 3 times, then feeding high-pressure inert protective gas argon into the test tube of the amorphous smelting furnace to carry out metal spray casting, and the high-pressure inert protective gas pressure is about 10Mpa;

[0052] (4) demoulding after spray casting to obtain the fully absorbed Mg-Zn-Ag amorphous alloy sample A2 of the present invention: Mg73Zn2...

Embodiment 3

[0055] (1) According to the designed alloy composition ratio, weigh 70at.%Mg, 26at.%Zn and 4at.%Ag on an electronic balance with an accuracy of 0.0001g;

[0056] (2) put the weighed Mg, Zn, Ag raw materials into the test tube of the amorphous smelting furnace, carry out mixed smelting in the presence of high-purity inert protective gas helium, and the high-purity inert protective gas pressure is 1 standard atmospheric pressure , the input voltage of the amorphous melting furnace is three-phase 380V 50-60Hz, the maximum power is 40kW, and the working current is 300-1800A;

[0057] (3) remelting the obtained alloy at least 3 times, then feeding high-pressure inert protective gas helium into the test tube of the amorphous smelting furnace to carry out metal spray casting, and the high-pressure inert protective gas pressure is about 10Mpa;

[0058] (4) demoulding after spray casting to obtain the fully absorbed Mg-Zn-Ag amorphous alloy sample A3 of the present invention: Mg73Zn23A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com