Preparation technology of burnishing treatment agent

A technology for preparation process and treatment agent, which is applied in the field of preparation of coke polishing treatment agent, which can solve the problems of powdery, oily and burnt feeling on the leather surface, easy mold on the leather surface, etc., so as to improve the anti-mildew effect and water resistance Effect and temperature resistance, strong color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

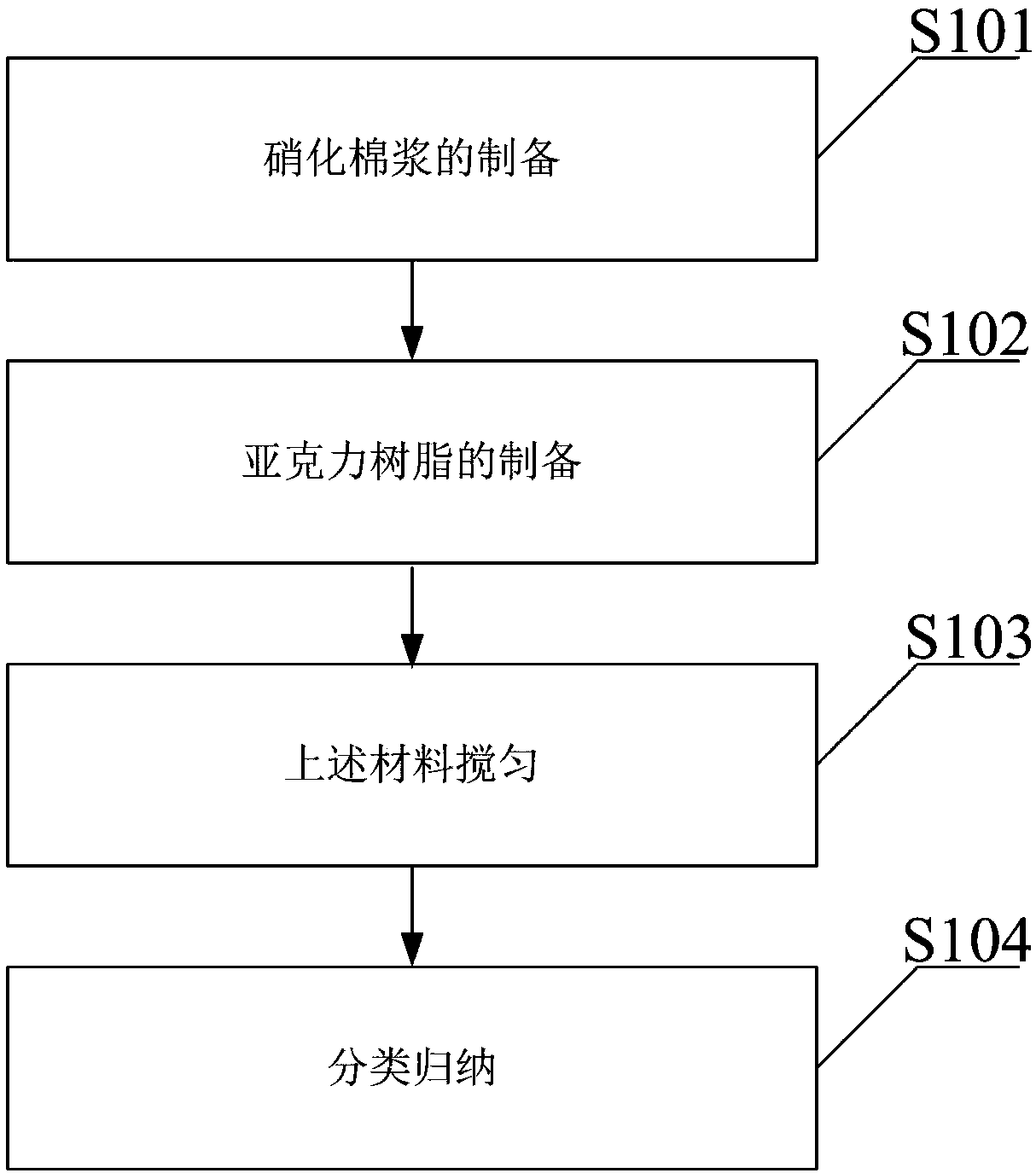

[0029] A kind of preparation technology of coke throwing treatment agent specifically comprises the following steps:

[0030] S101: Preparation of nitrocellulose pulp; the nitrocellulose pulp uses nitrocellulose powder and butyl acetate as raw materials, adds nitrocellulose powder and butyl acetate in the stirring equipment, and uses the stirring equipment to mix the nitrocellulose powder and butyl acetate in the Mix and stir at a suitable temperature for a certain period of time.

[0031] S102: Preparation of acrylic resin; the acrylic resin uses acrylic powder and DMF as raw materials, adds acrylic powder and DMF into a stirring device, and uses the stirring device to mix the acrylic powder and DMF evenly within a certain period of time.

[0032] S103: Prepare and stir the above materials; the above materials use nitrocellulose pulp and acrylic resin as raw materials, add nitrocellulose pulp and acrylic resin into the stirring equipment, and use the stirring equipment to mix...

Embodiment 1

[0046] Embodiment 1: during the preparation of nitrocellulose pulp, the nitrocellulose pulp is made of nitrocellulose powder and butyl acetate as raw materials, and the ratio of parts by weight of nitrocellulose powder and butyl acetate is set to 1:1 in the chemical industry Add the nitrocellulose powder and butyl acetate in the above ratio into the powder multi-purpose mixer, and use the chemical powder multi-purpose mixer to mix the nitrocellulose powder and butyl acetate for 1.5 hours at 20°C; then put the The acrylic resin is made of acrylic powder and DMF with a weight ratio of 3:1 as the raw material. Add acrylic powder and DMF into the chemical powder multi-purpose mixer, and use the chemical powder multi-purpose mixer to mix the acrylic powder and DMF within 2.5 hours. Mix and stir; then use nitrocellulose pulp and acrylic resin as raw materials for the above materials, add nitrocellulose pulp and acrylic resin in the stirring equipment, and use the stirring equipment t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com