Improved type shockproof self-locking bolt

An improved, self-locking technology, applied to bolts, screws, nuts, etc., can solve the problem of easy rotation, loosening and falling off of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

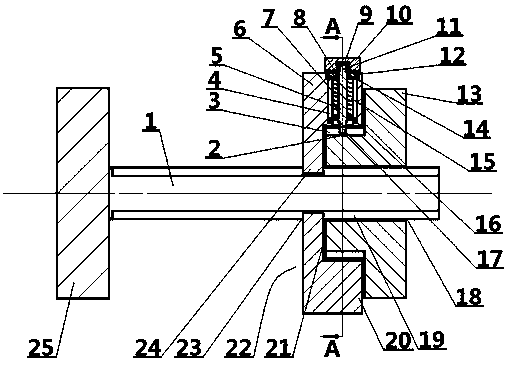

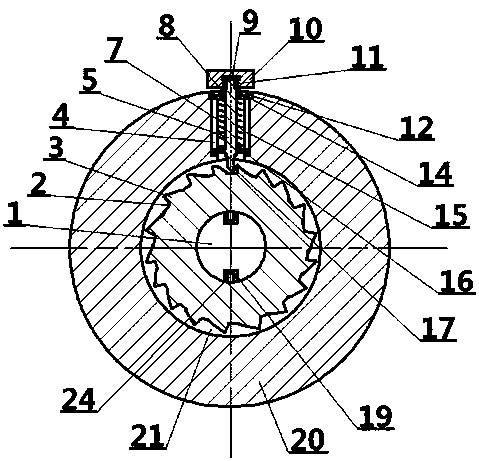

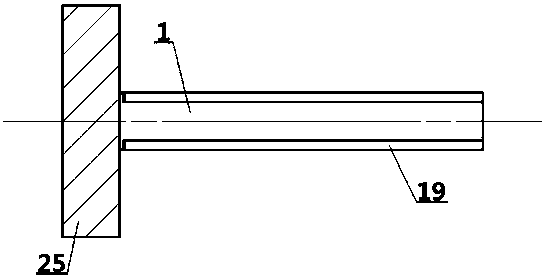

[0032] Example: such as Figure 1-6 As shown, an improved anti-vibration self-locking bolt is designed and manufactured, including a screw 1 and a nut 13. The left end of the screw 1 is provided with an integrally formed screw head 25, and the nut 13 cooperates with the screw 1 through the large threaded hole 18 on its axis. connect.

[0033] A spring washer is sheathed on the screw rod 1 on the left side of the nut 13 .

[0034] The screw head 25 is an outer hexagonal structure.

[0035] The main features of the present invention are: the upper and lower ends of the screw 1 are respectively provided with corresponding locking grooves 19, and the right end of the locking grooves 19 is in an open state.

[0036] The left end of the nut 13 is set as an annular boss 2, and the circumference of the outer diameter end of the annular boss 2 is provided with integrally formed, evenly distributed serrations 3, and the orientation of the tooth tips is set in the counterclockwise direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com