An experimental device for measuring the thickness of the airflow boundary layer near the wall of an inverted V-shaped aircraft

A technology of thickness measurement and experimental equipment, applied in the field of experimental mechanics, can solve the problems of difficulty in improving spatial resolution, complicated installation and operation, etc., and achieve the effect of simple structure, fine measurement and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

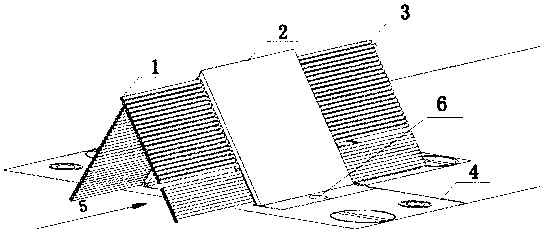

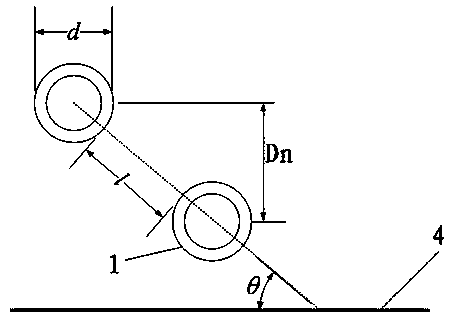

[0047] Such as figure 1 As shown, the device for measuring the thickness of the airflow boundary layer near the wall of the present invention includes a rake body and an air inlet pipe and an air outlet pipe arranged on the rake body, wherein the rake body is arranged on a flat plate model, and the flat plate model plays a supporting role. The rake body in the present invention changes the traditional single-sided straight plate shape, adopts a V-shaped structure, and changes the relative distance between the intake pipes through the V-shaped design, thereby reducing the influence on the state of the flow field.

[0048] In the present invention, the surface part of the V-shaped rake body exposing the flat plate model is a V-shaped thin plate with a thickness of 2mm. The distance from the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com