Automatic loading tooling for rear wall outer panel assembly

The technology of the outer panel and the assembly is applied in the field of automatic loading and tooling of the rear outer panel assembly, which can solve the problems of low position accuracy of the upper part of the rear outer panel assembly, inability to guarantee the welding accuracy, and low labor cost, etc. Achieve the effect of being conducive to accurate positioning, safe and reliable locking, and low labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

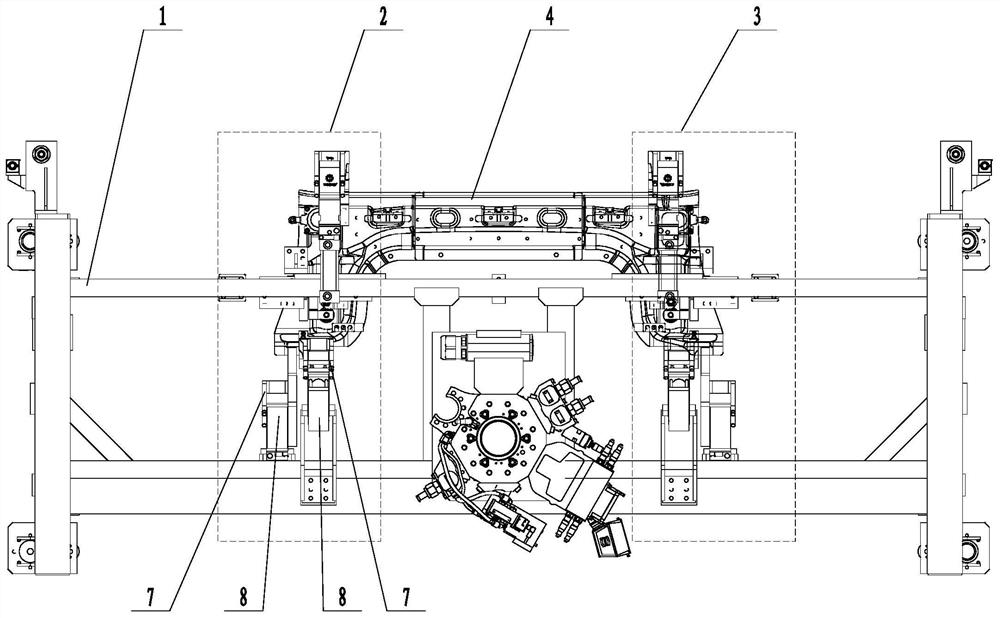

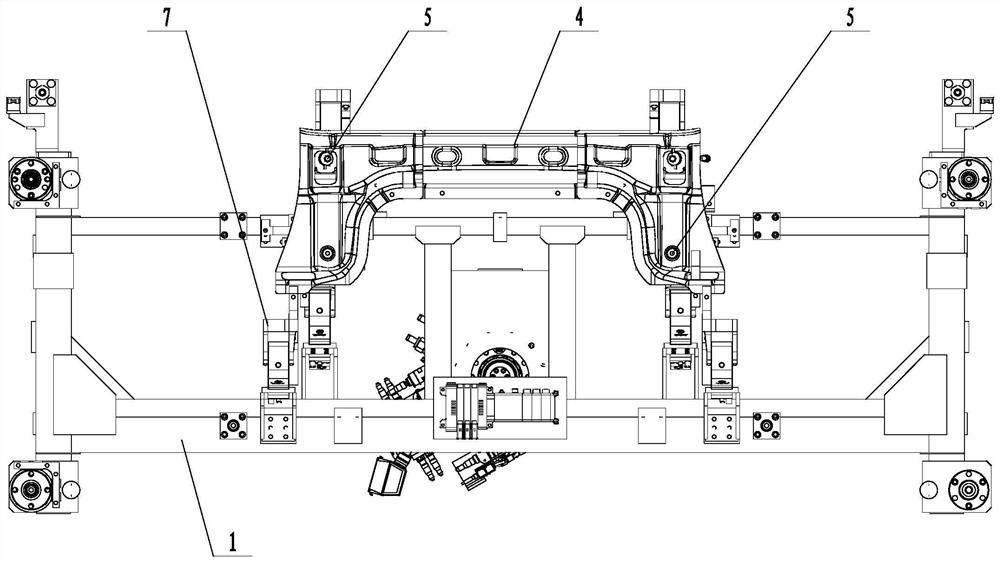

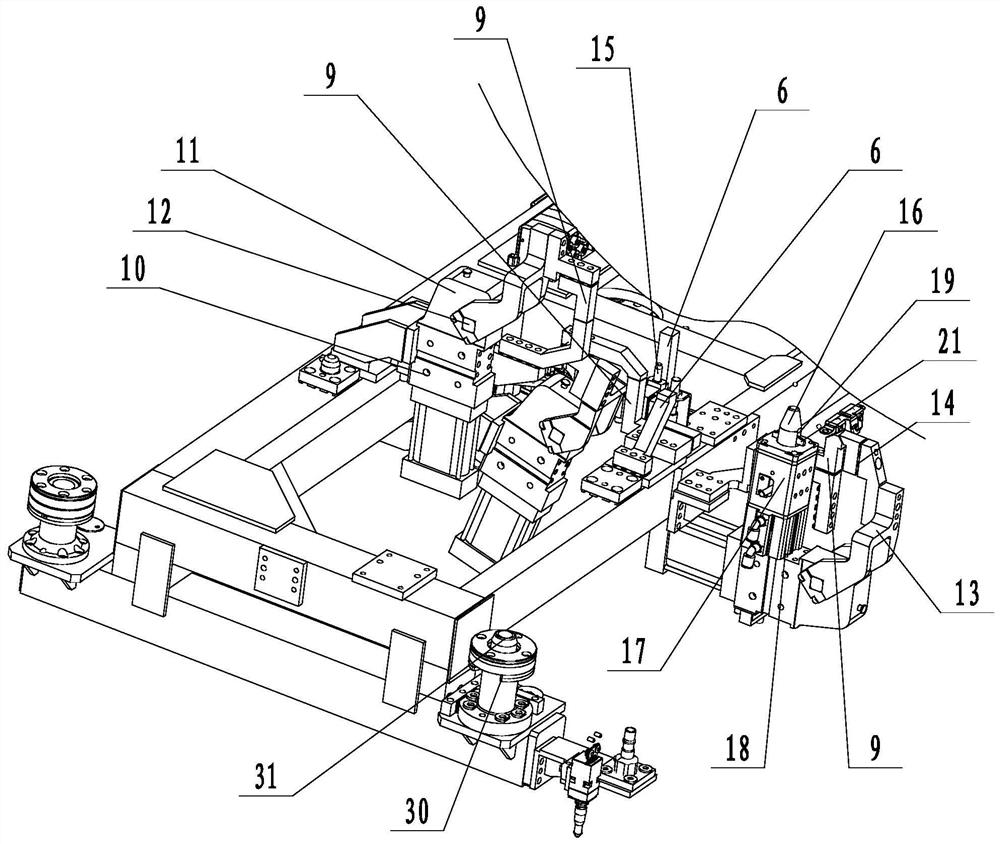

[0028] Example: A tooling for automatic loading of rear wall outer panel assembly (see attached Figure 1 to 6 ), including a rectangular mounting frame 1 for connecting with the robot arm. The four corners of the mounting frame are all equipped with positioning posts 30, of which positioning heads 31 are provided on the two diagonal positioning posts. A left positioning and clamping mechanism 2 and a right positioning and clamping mechanism 3 are tightly connected to the mounting frame. The left positioning and clamping mechanism 2 and the right positioning and clamping mechanism 3 are symmetrically arranged on the left and right sides of the mounting frame. The left positioning and clamping mechanism and the right positioning and clamping mechanism both include several positioning pins 5 corresponding to the through holes on the rear wall outer panel assembly 4, several support columns 6, several clamping heads 7, and clamping heads The driving mechanism 8 is connected, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com