Hardware tool abrasive belt polishing machine

A technology for abrasive belt polishing and hardware tools, which is applied to manufacturing tools, abrasive belt grinders, metal processing equipment, etc., can solve the problems of difficulty in adjusting the tightness of the abrasive belt, the angle of polishing is not easy to adjust, and the assembly efficiency is reduced. Installation efficiency, compact structure, easy assembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

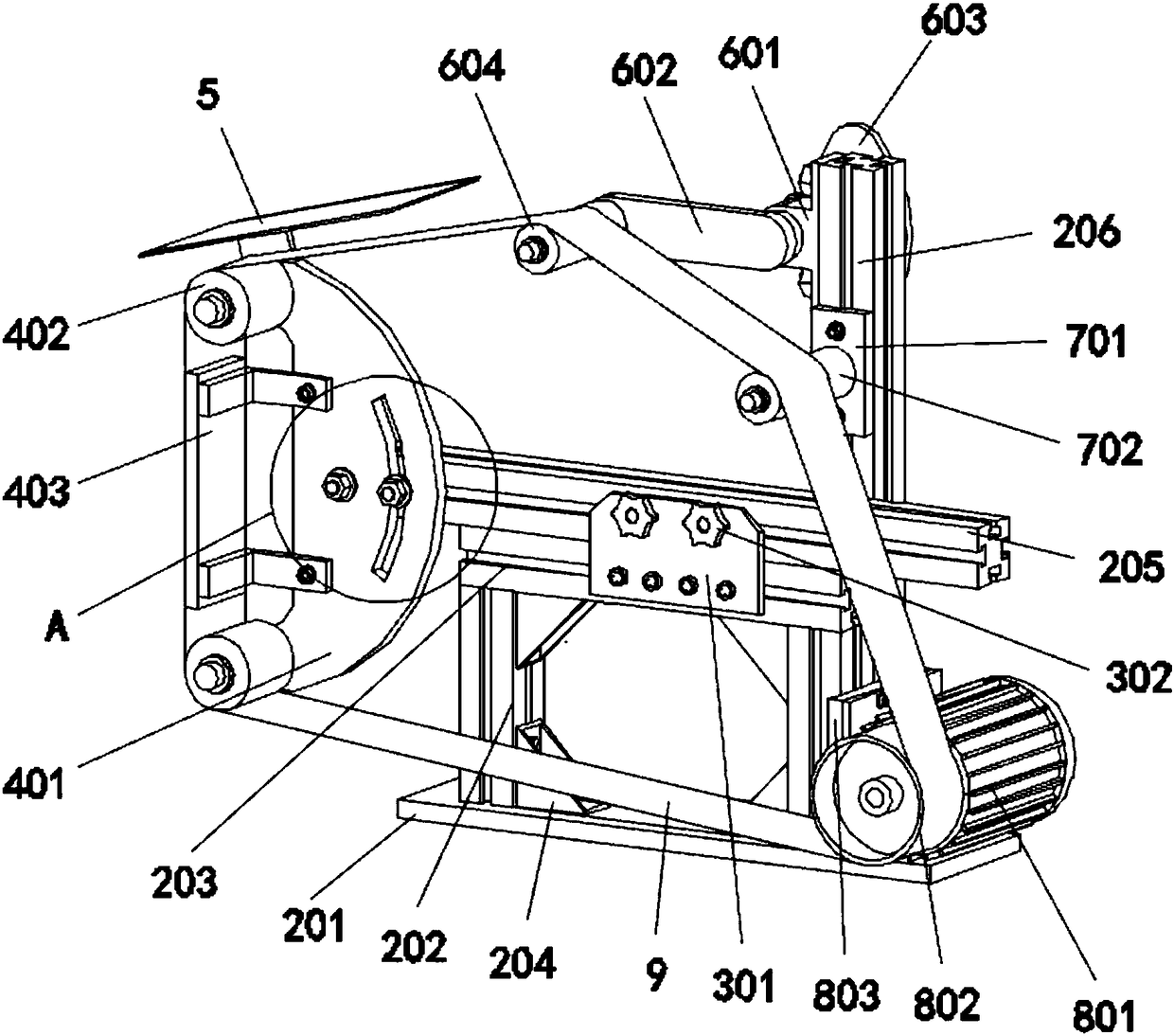

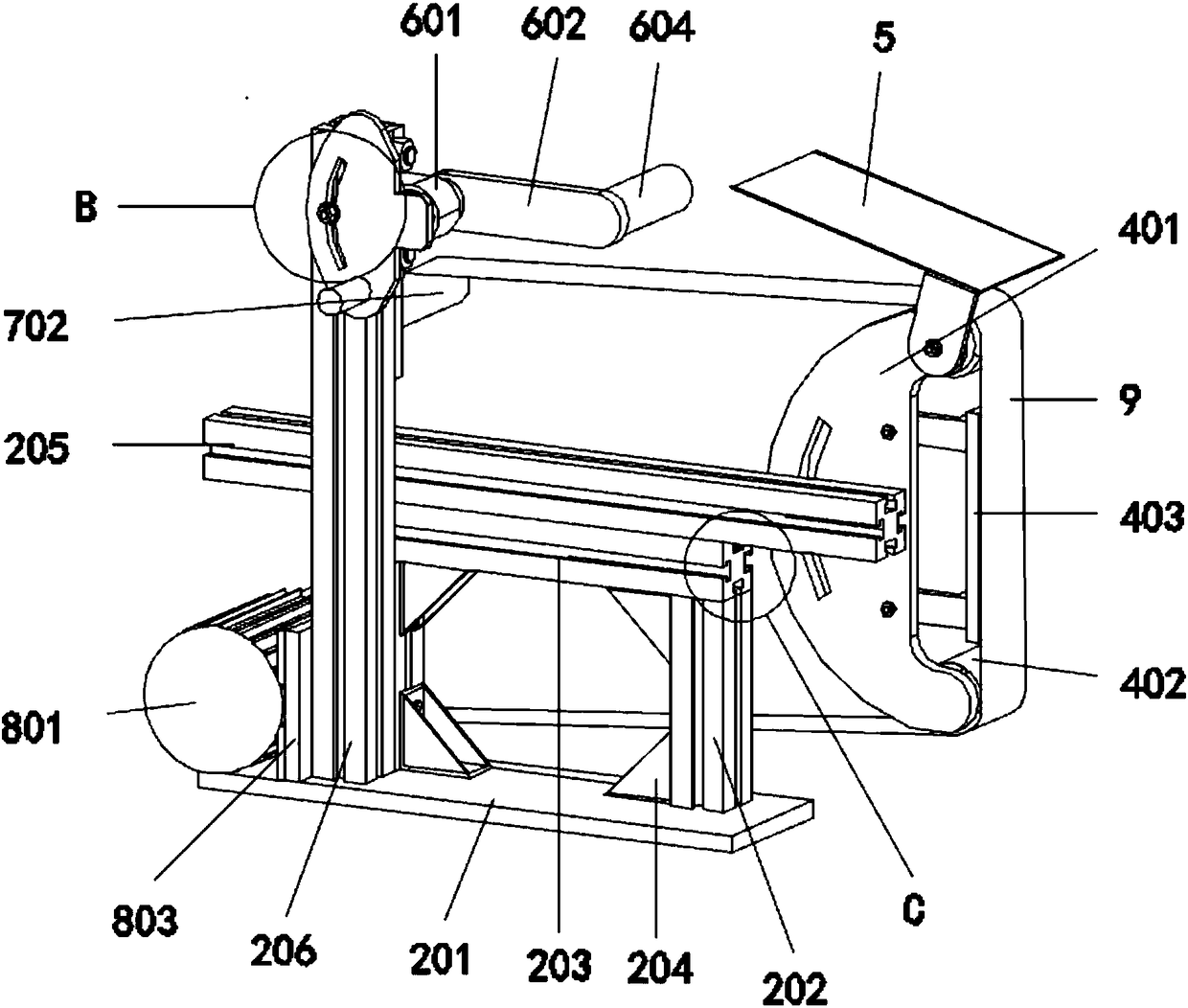

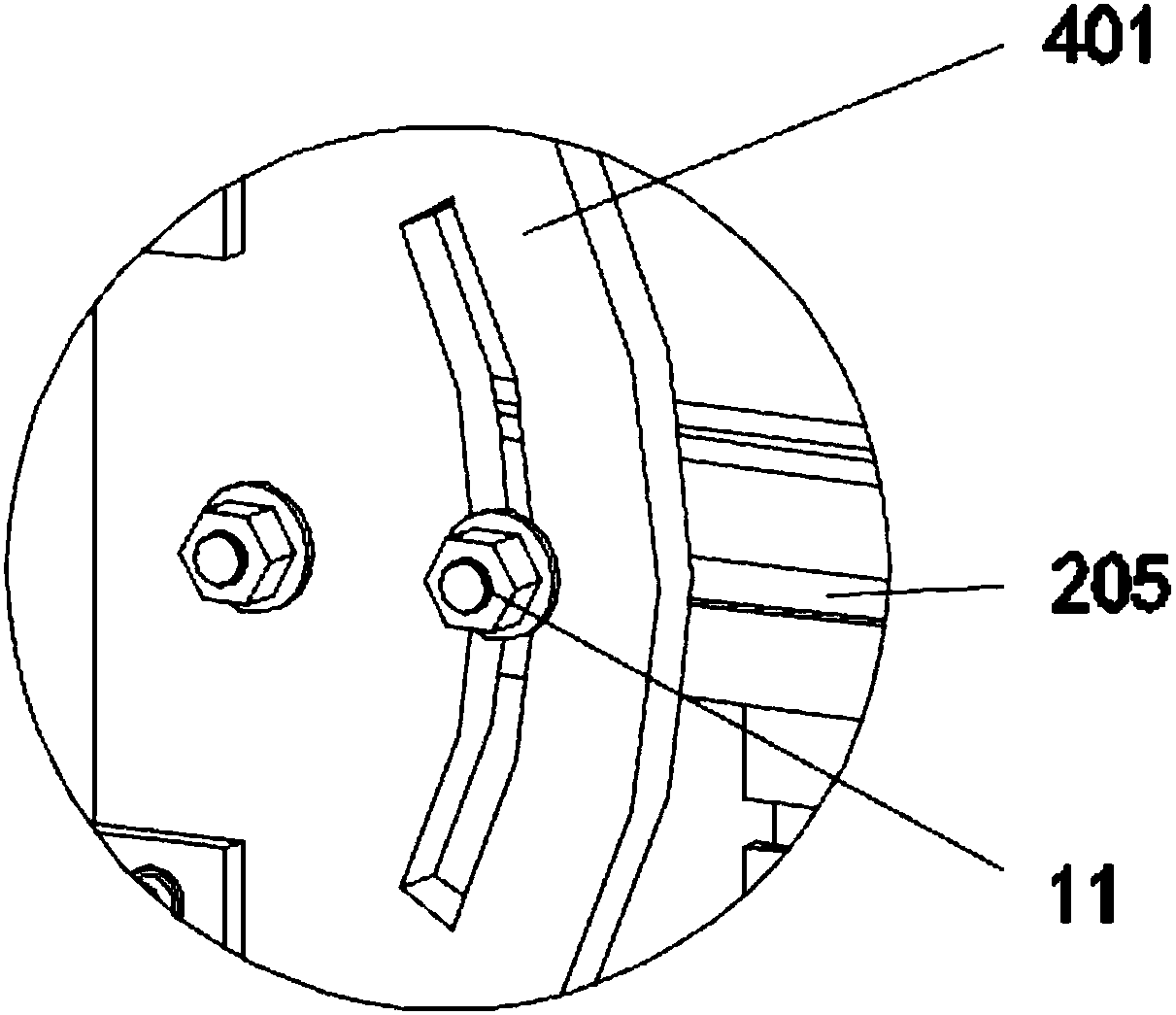

[0036] An abrasive belt polishing machine for hardware tools, comprising: a machine body 1, a frame 2, a locking lever device 3, a polishing device 4, a guard plate 5, a tension adjusting device 6, a guiding device 7, a driving device 8, an abrasive belt 9, and a guide rail 10 , Bottom plate 201, vertical bar 202, cross bar 203, reinforcement plate 204, slide bar 205, support bar 206, connecting plate 301, handle bolt 302, swing plate 401, driven wheel 402, polishing plate 403, fixed seat 601, adjustment arm 602, adjusting plate 603, adjusting wheel 604, fixed plate 701, guide wheel 702, driving motor 801, driving wheel 802, mounting plate 803; body 1 includes frame 2 and locking bar device 3 installed on frame 2 , polishing device 4, tension adjusting device 6, guiding device 7, driving device 8 and abrasive belt 9; Vertical bar 202 is vertically arranged on the top of base plate 201, and the lower end of vertical bar 202 is connected with base plate 201 by bolt; Cross bar 203...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com