Reversing image camera assembly for vehicle

A camera assembly, reversing image technology, applied in the field of vehicle parts, can solve the problems of increasing labor cost, increasing economic cost, large volume and quality, etc., and achieve the effect of saving labor cost, optimizing assembly cost, and simplifying manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

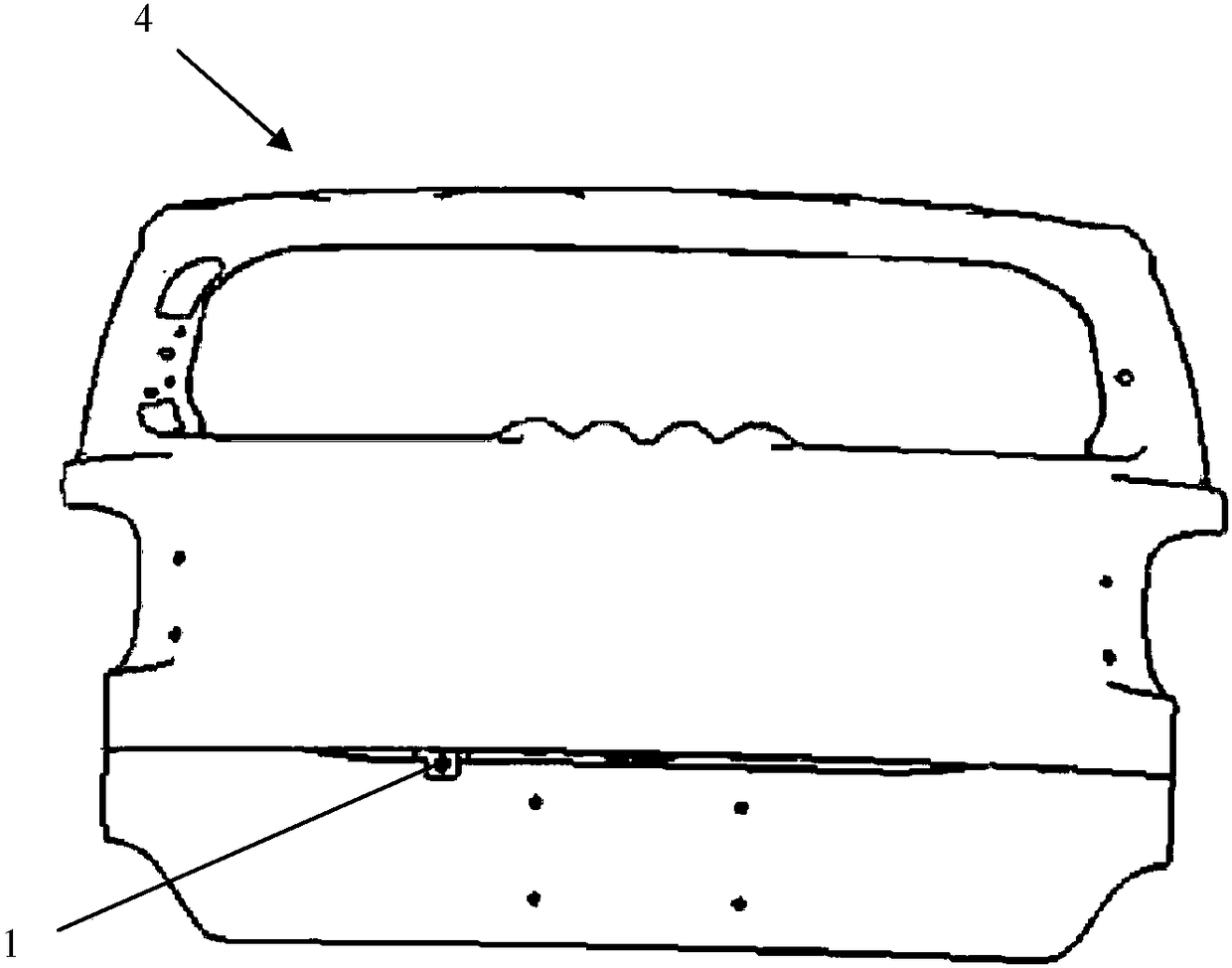

[0031] figure 1 is a schematic diagram of the rear cover 4 of the vehicle, wherein the installation position of the camera 1 is shown as an example. It should be understood that for different types of vehicles (such as cars, sports utility vehicles (SUVs), trucks, etc.), the rear covers have different shapes, and the rear view camera assembly according to the present invention is not limited to be mounted on figure 1 installation location shown. In fact, the reversing image camera assembly according to the present invention can be installed on any position where the real-time image of the rear of the vehicle can be clearly captured and is easy to install (usually on the rear cover or rear bumper of the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com