Aeration pipe structure

A technology of aeration tube and tube body, which is applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc. It can solve the problems of high equipment cost, reduced bubble function, energy consumption, etc., and achieve cost reduction And equipment costs, increase the service life, reduce the effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable your examiner to have a further understanding and recognition of the features and features of the present invention, the following preferred embodiments are now listed and described as follows in conjunction with the drawings:

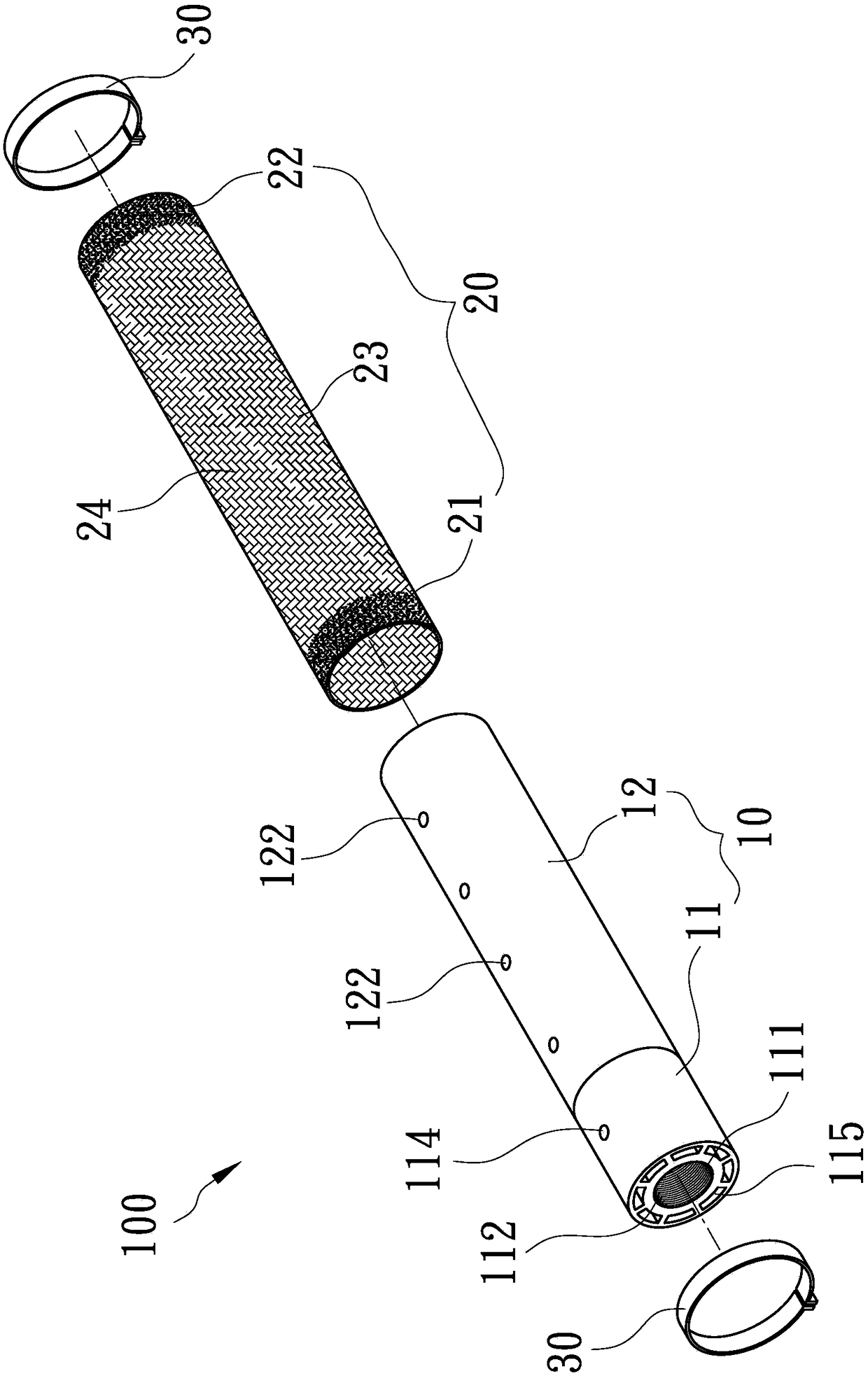

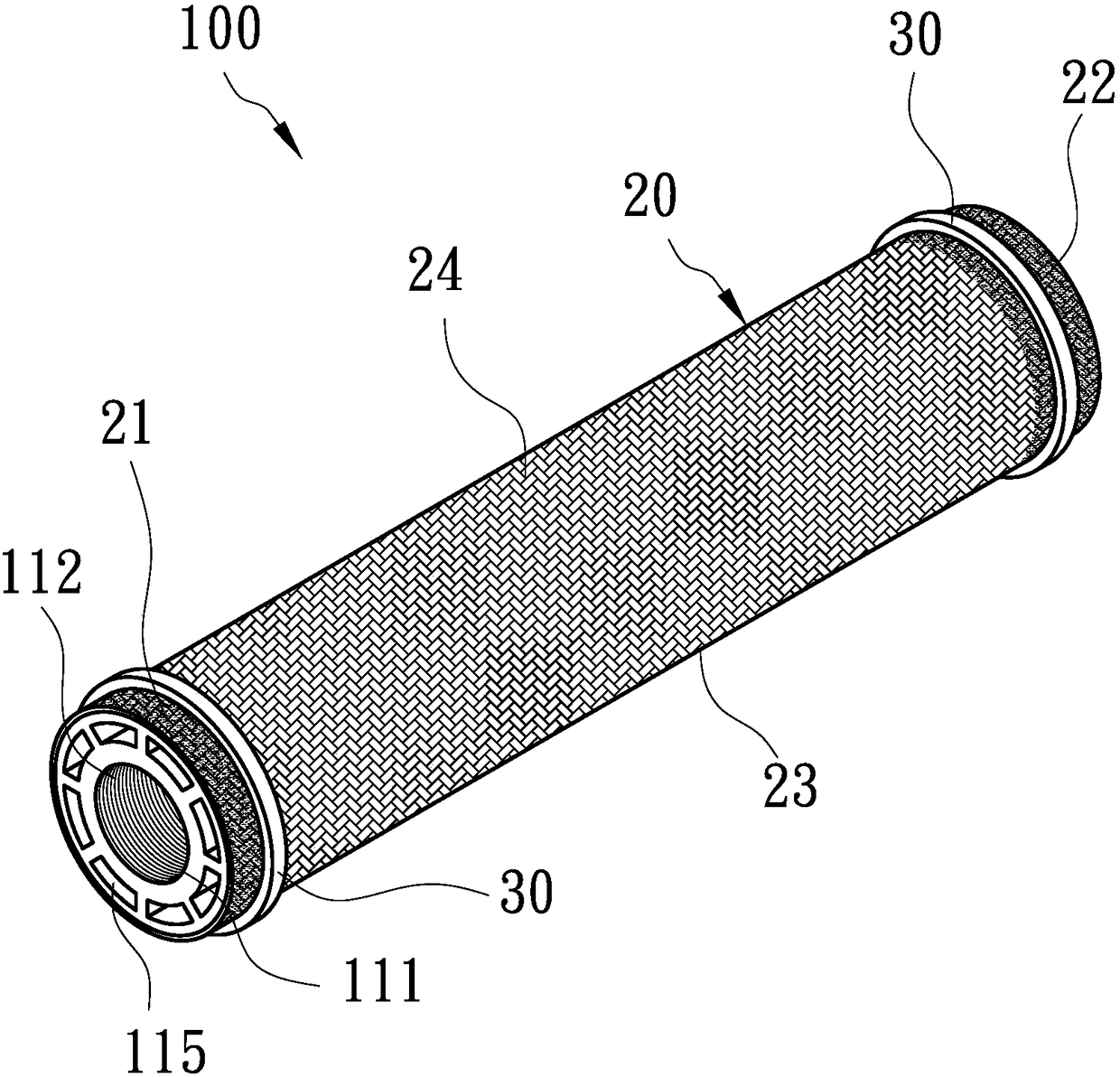

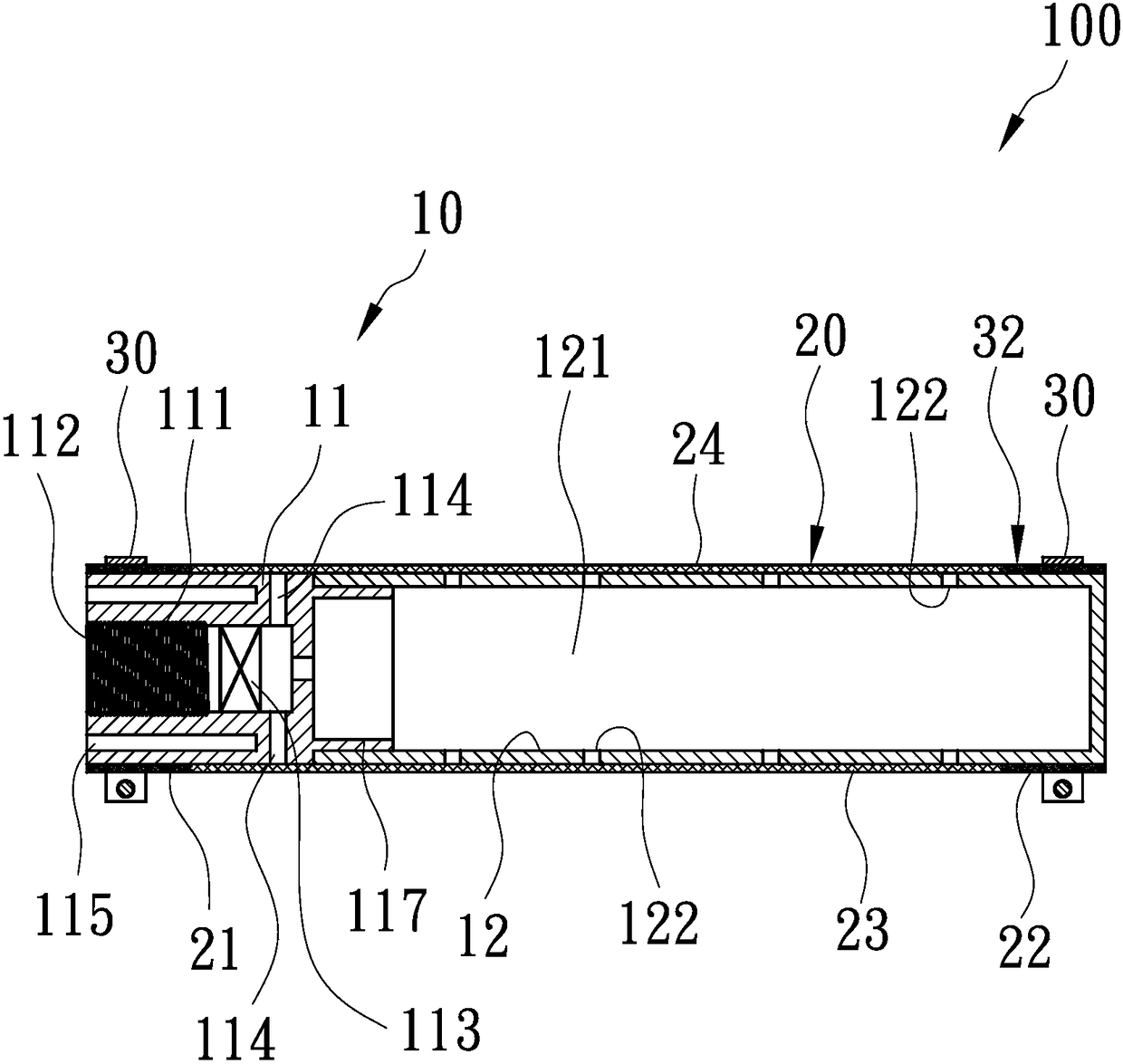

[0027] see Figure 1-Figure 8 , is an aeration pipe structure 100 provided by a preferred embodiment of the present invention, which includes a pipe body 10, a braided sheath 20 and two bundle rings 30, wherein:

[0028] see Figure 1-Figure 4 , the tube body 10 has a connector 11 and an inner tube 12 . The axis of the connector 11 has an air guide hole 111 that runs through the front and rear ends. The inner wall of the front section of the air guide hole 111 has an internal thread 112. A check valve 113 is arranged in the rear section of the air guide hole 111. By the air guide hole 111 After air supply, the fluid can only enter from the front section of the air guide hole 111 to the rear section, but cannot enter from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com