Elastic flow channel regulating particles and preparation method thereof

An elastic and granular technology, applied in the field of elastic flow regulating particles and their preparation, can solve problems such as water channeling in weathering crust reservoirs, and achieve the effects of improving product value, easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

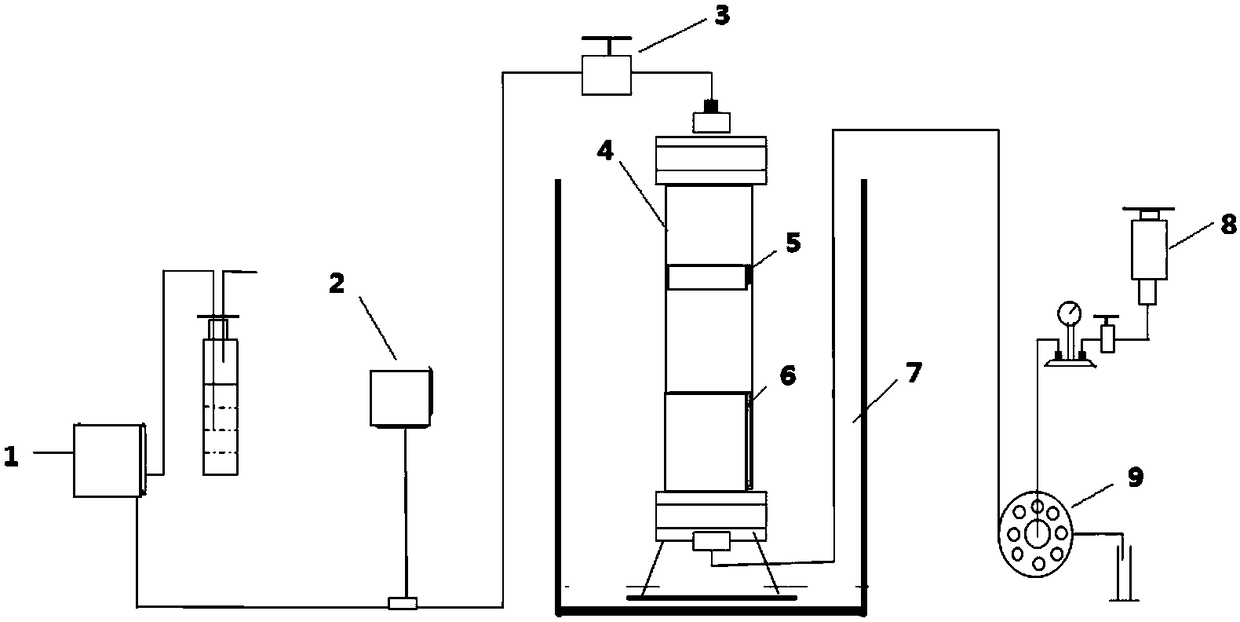

Method used

Image

Examples

preparation example Construction

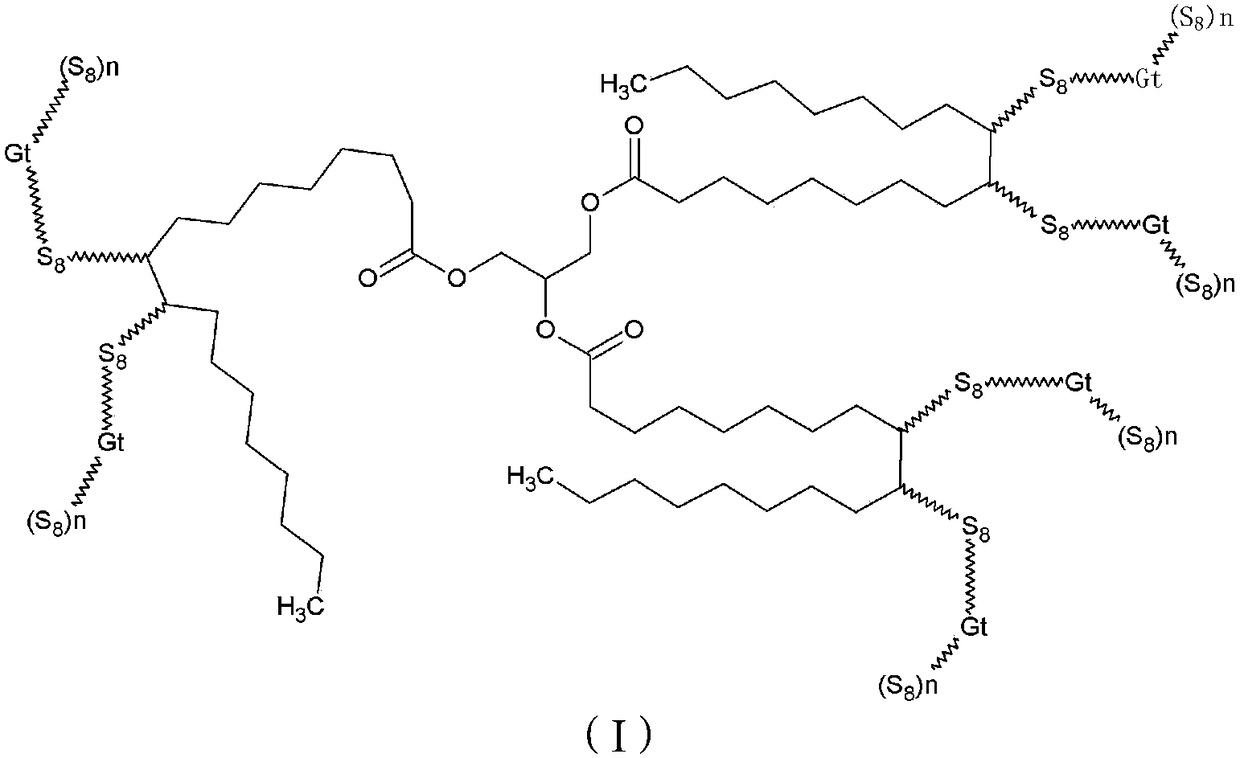

[0034] The second aspect of the present invention provides a method for preparing elastic flow-regulating particles, including: (1) heating sulfur to completely melt into a liquid to obtain liquid sulfur; (2) mixing the liquid sulfur with crude vegetable oil or oil bottoms evenly, Then, the reaction is carried out by raising the temperature to obtain solid sulfur rubber particles; (3) granulating and sorting the solid sulfur rubber particles to obtain elastic flow regulating particles.

[0035] In a preferred embodiment, the preparation method of the elastic flow regulating particles of the present invention comprises the following steps:

[0036] In the first step, sulfur is heated to 130°C to 150°C to completely melt it into a liquid to obtain liquid sulfur.

[0037] Sulfur is a light yellow brittle crystal or powder in appearance. It has a wide range of sources and can be obtained in desulfurization treatment and recovery of various oil and gas fields with high hydrogen sul...

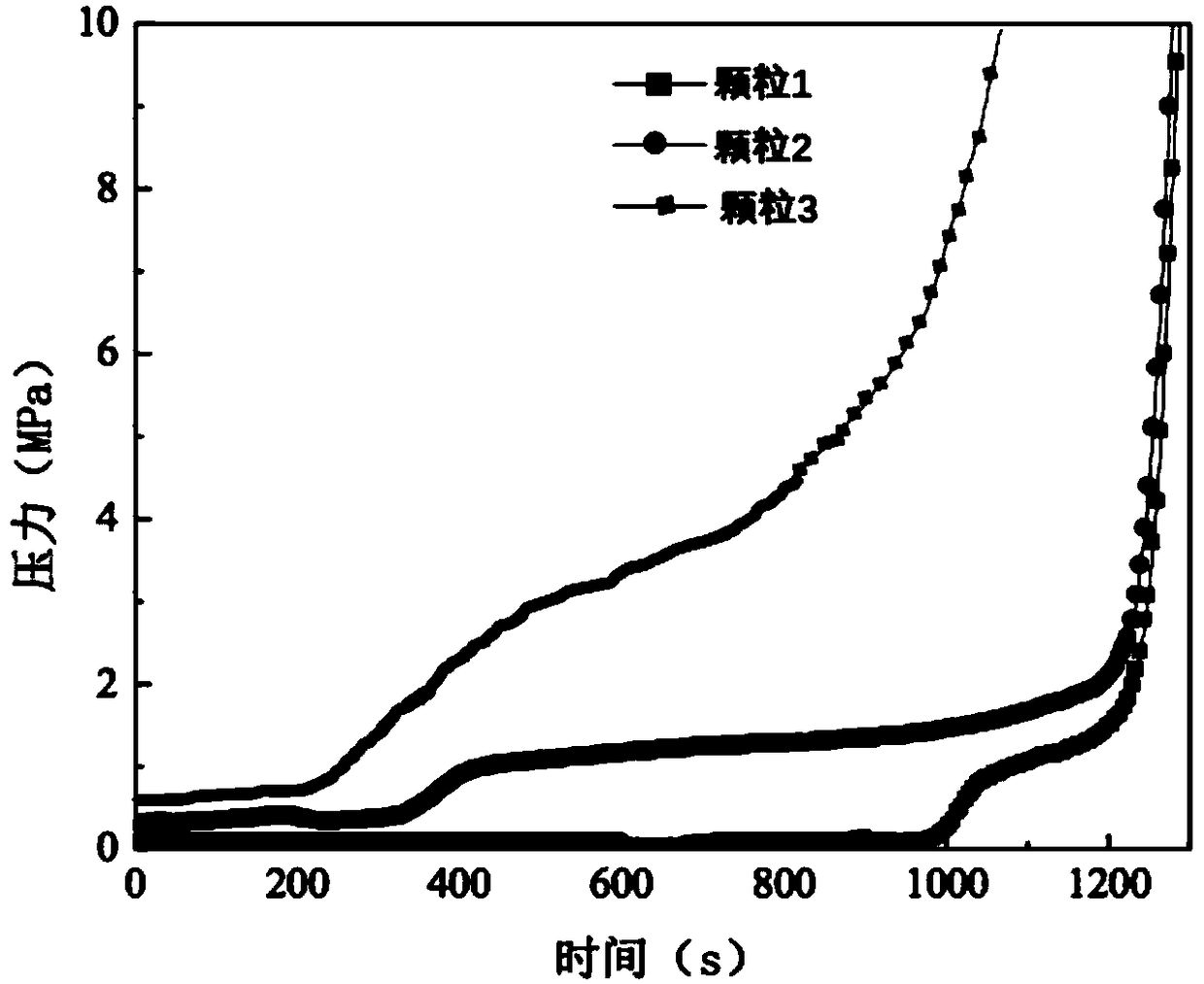

Embodiment 1

[0047]Add 50g of industrial sulfur into a 250mL beaker, start the stirrer, the temperature rises to 140°C, and after it is completely melted into a liquid, add 52.5g of vegetable crude oil preheated to 140°C, continue stirring at 140°C for 0.5 hours, and raise the temperature to 180°C (heating frequency 2.0°C / min), constant temperature reaction for 0.45h to obtain solid sulfur rubber, after cooling, crush and sort to obtain particles with a particle size of 1-2 mm, namely to obtain elastic flow regulating particles of sulfur rubber 1.

Embodiment 2

[0049] Add 60g of industrial sulfur into a 250mL beaker, start the stirrer, and raise the temperature to 150°C. After it is completely melted into a liquid, add 40g of vegetable crude oil preheated to 150°C, continue stirring at 150°C for 0.3 hours, and then heat up to 180°C ( Heating frequency 3.0°C / min), constant temperature reaction for 0.5h, to obtain sulfur rubber solid, after cooling, crush and sort particles with a particle size of 3-5mm, and obtain sulfur rubber elastic flow-regulating particles 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com