Rail type bamboo breaking and stewing device

An orbital, stewing technology, applied in the field of papermaking, can solve problems such as the failure of steam pipelines, affecting product quality, and waste of human resources, so as to overcome uneven lye soaking, shorten cooking time, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

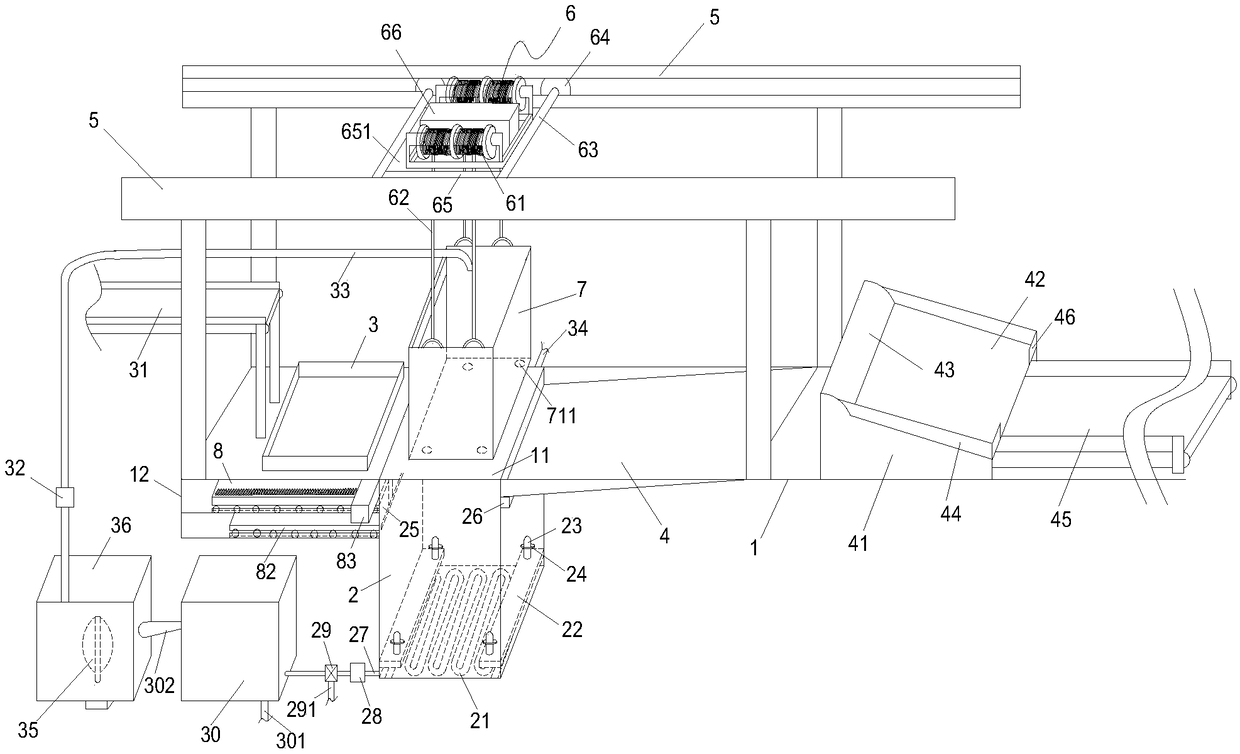

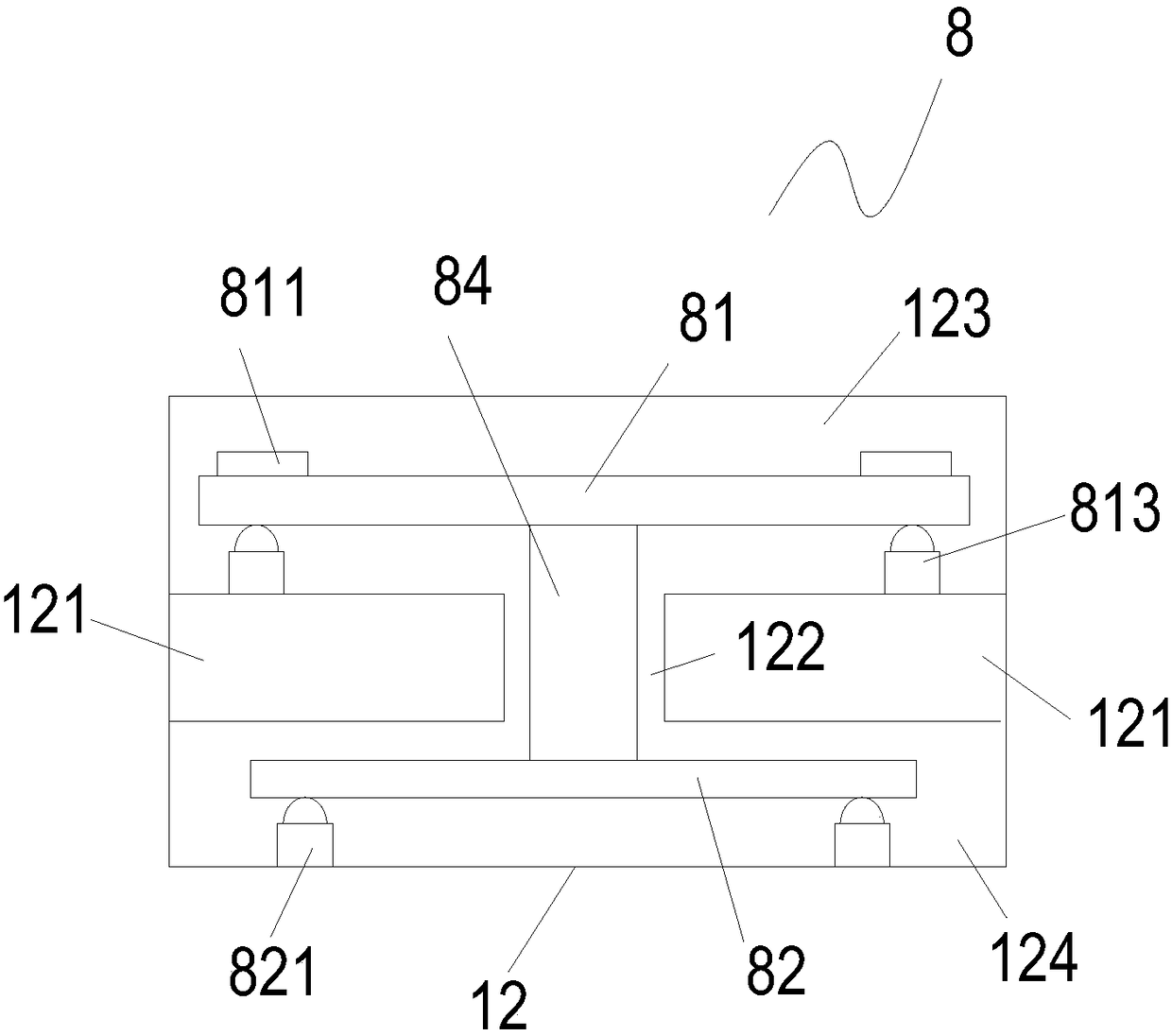

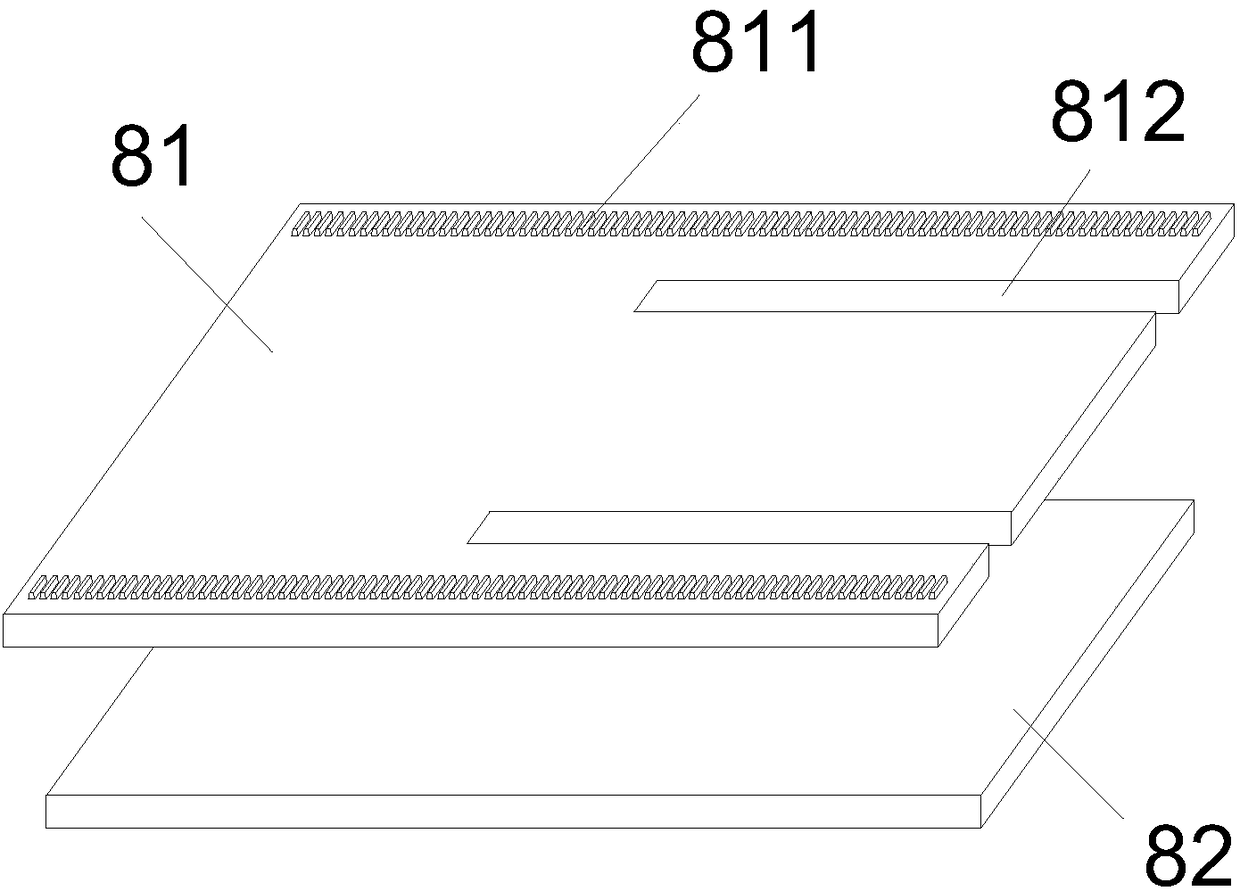

[0019] see Figure 1 to Figure 6 As shown, a kind of orbital broken bamboo stewing device of the present invention comprises a workbench 1, and an opening 11 is provided on the said workbench 1, and a stewing pool 2 is arranged under the opening 11, and the stewing pool 2 is provided with a heating tube 21, and two support plates 22 are horizontally arranged on the two side walls of the stewing pool 2, so that the stewing tank can be erected above the heating tube through the two support plates, so that the stewing tank can be better Stewing; both ends of the support plate 22 are vertically provided with a sealing column 23, the sealing column 23 is provided with a sealing ring 24, and the workbench 1 is provided with a limit frame 3, a water receiving tank body 4, and two Track 5; the limiting frame 3 is located in front of the opening 11, the water receiving tank 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com