Heliostat main beam machining equipment

A technology for processing equipment and heliostats, which is applied in the field of heliostat main beam processing equipment, can solve the problems of rigidity, inability to arrange drilling spindle modules, and affecting the stability of drilling accuracy, so as to ensure processing accuracy and realize The effect of high-precision modular production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

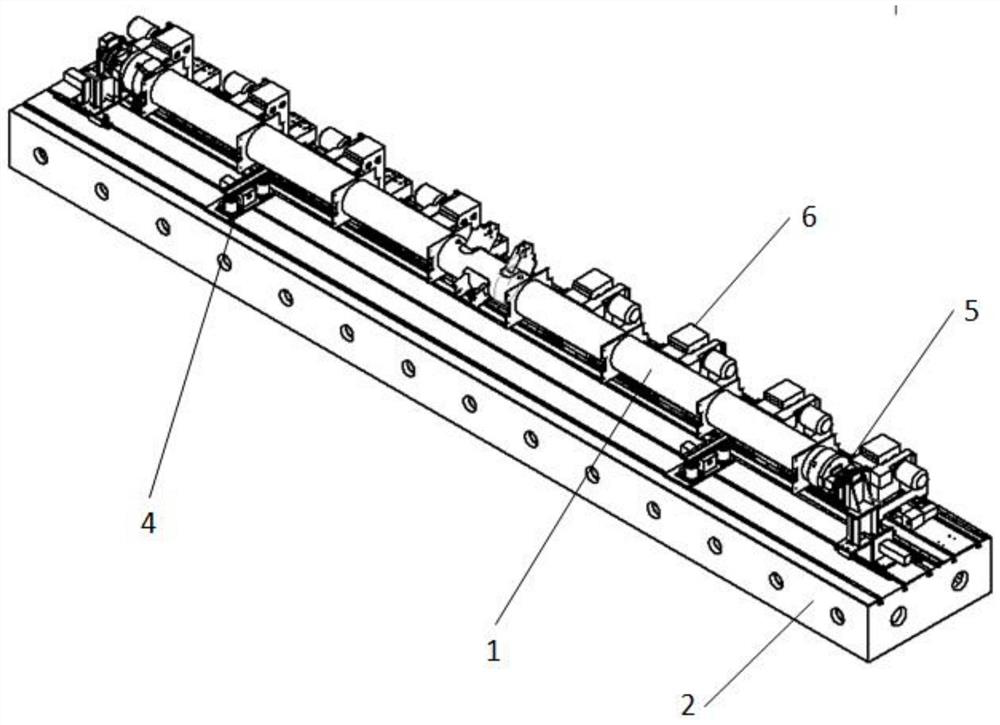

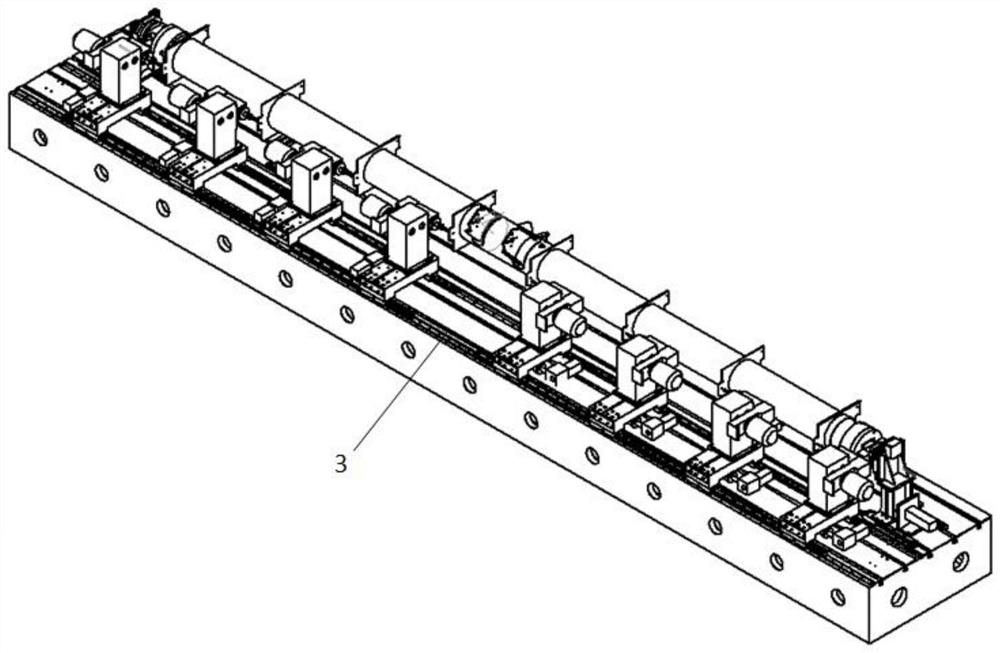

[0042] see Figure 1 to Figure 2 As mentioned above, the present invention provides a heliostat main beam processing equipment, including a base 2 , a longitudinal guide rail unit 3 , a main beam support unit 4 , a main beam adjustment unit 5 , and at least one main beam processing unit 6 .

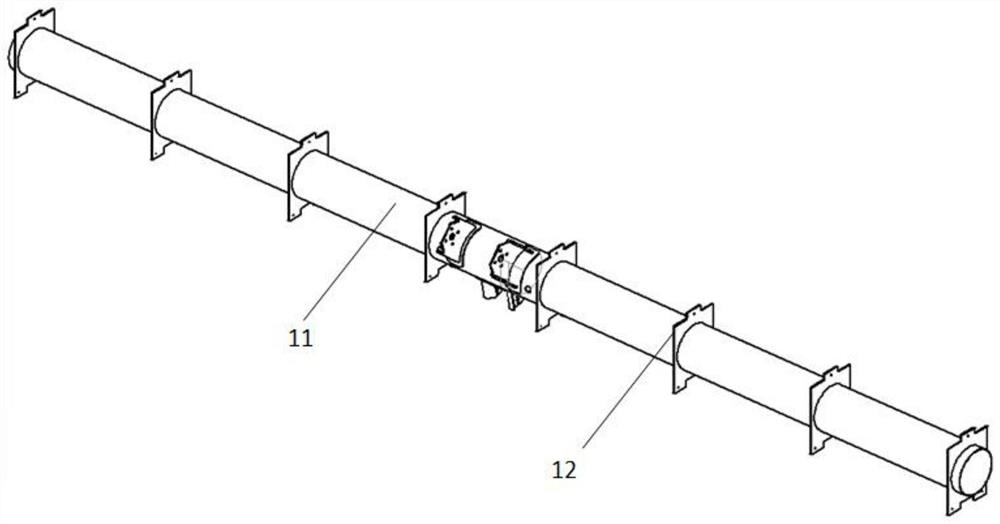

[0043] The processing object of the present invention is the heliostat main beam 1, see image 3 As shown, the heliostat main beam 1 includes a longitudinally extending main beam body 11 and at least one support assembly 12 fixedly arranged on the main beam body 11. In this embodiment, eight support assemblies 12 are symmetrically distributed to the center The way is welded on the main beam main body 11. Specifically, the core element that affects the accuracy of the heliostat frame is the processing holes distributed on the support components. In this embodiment, each support component 12 is distributed with three processing holes, and the centers of the three processing holes constitut...

Embodiment 2

[0059] Based on the same inventive concept, the present invention is improved on the basis of Embodiment 1. This embodiment provides a heliostat main beam processing equipment, which not only includes a base 2, a longitudinal guide rail unit 3, a main beam support unit 4, The main beam adjustment unit 5 and at least one main beam processing unit 6 also include an eccentric adjustment unit 7 for adjusting the relative position of the support assembly 12 and the drilling spindle mechanism 63 in the radial direction.

[0060] The processing object of this embodiment is the heliostat main beam 1, see image 3 As shown, the heliostat main beam 1 includes a longitudinally extending main beam body 11 and at least one support assembly 12 fixedly arranged on the main beam body 11. In this embodiment, eight support assemblies 12 are symmetrically distributed to the center The way is welded on the main beam main body 11. Specifically, the core element that affects the accuracy of the he...

Embodiment 3

[0073] Based on the same inventive concept, the present invention is improved on the basis of Embodiment 1, see Figure 18-Figure 19 As shown, this embodiment provides a heliostat main beam processing equipment, which not only includes a base 2, a longitudinal guide rail unit 3, a main beam support unit 4, a main beam adjustment unit 5, and at least one main beam processing unit 6, but also An eccentric adjustment unit 7 is included for adjusting the relative position of the support assembly 12 and the drilling spindle mechanism 63 in the radial direction.

[0074] The processing object of this embodiment is the heliostat main beam 1, see image 3 As shown, the heliostat main beam 1 includes a longitudinally extending main beam body 11 and at least one support assembly 12 fixedly arranged on the main beam body 11. In this embodiment, eight support assemblies 12 are symmetrically distributed to the center The way is welded on the main beam main body 11. Specifically, the core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com