Crushed bamboo boiling equipment for preparation of bamboo pulp

A technology of stewing and bamboo pulp, which is applied in the field of papermaking, can solve the problems of steam pipelines, affecting product quality, and waste of human resources, so as to overcome uneven lye soaking, shorten cooking time, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

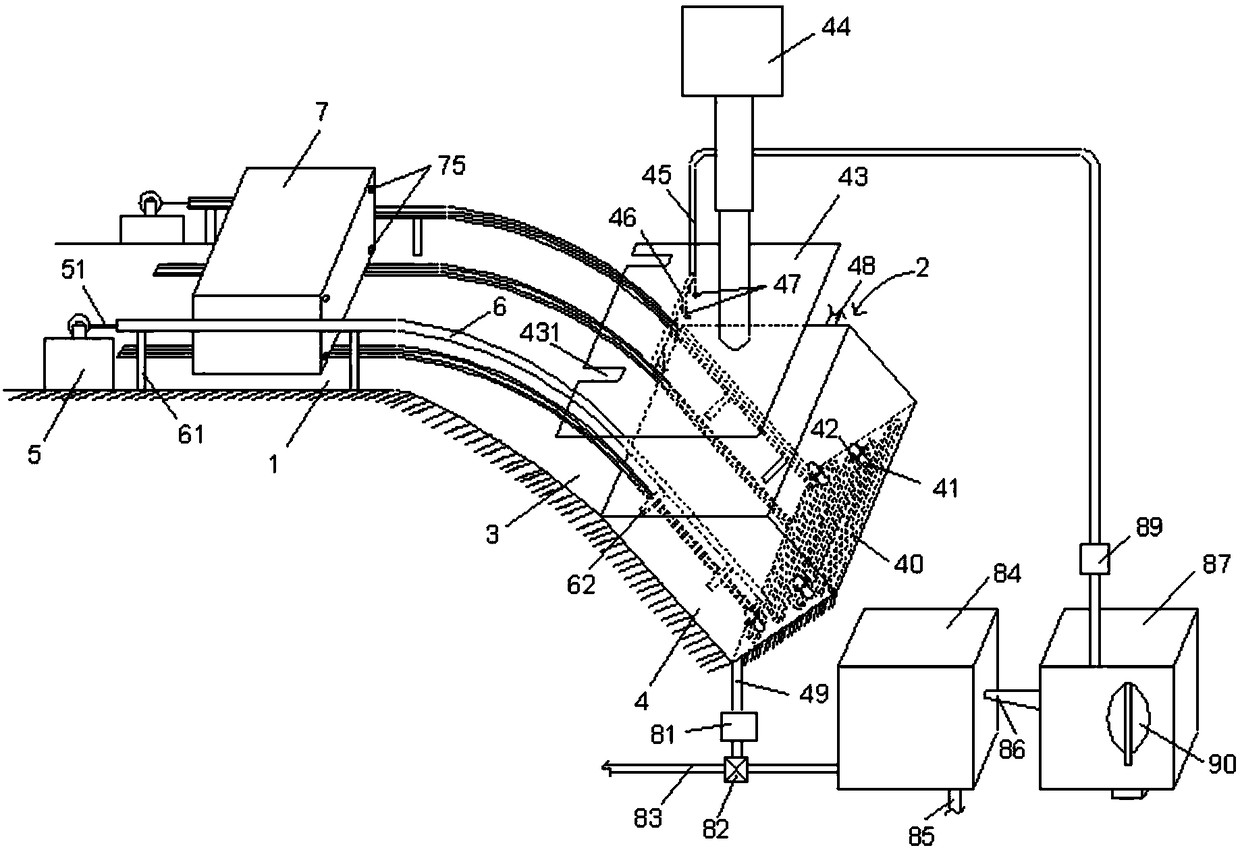

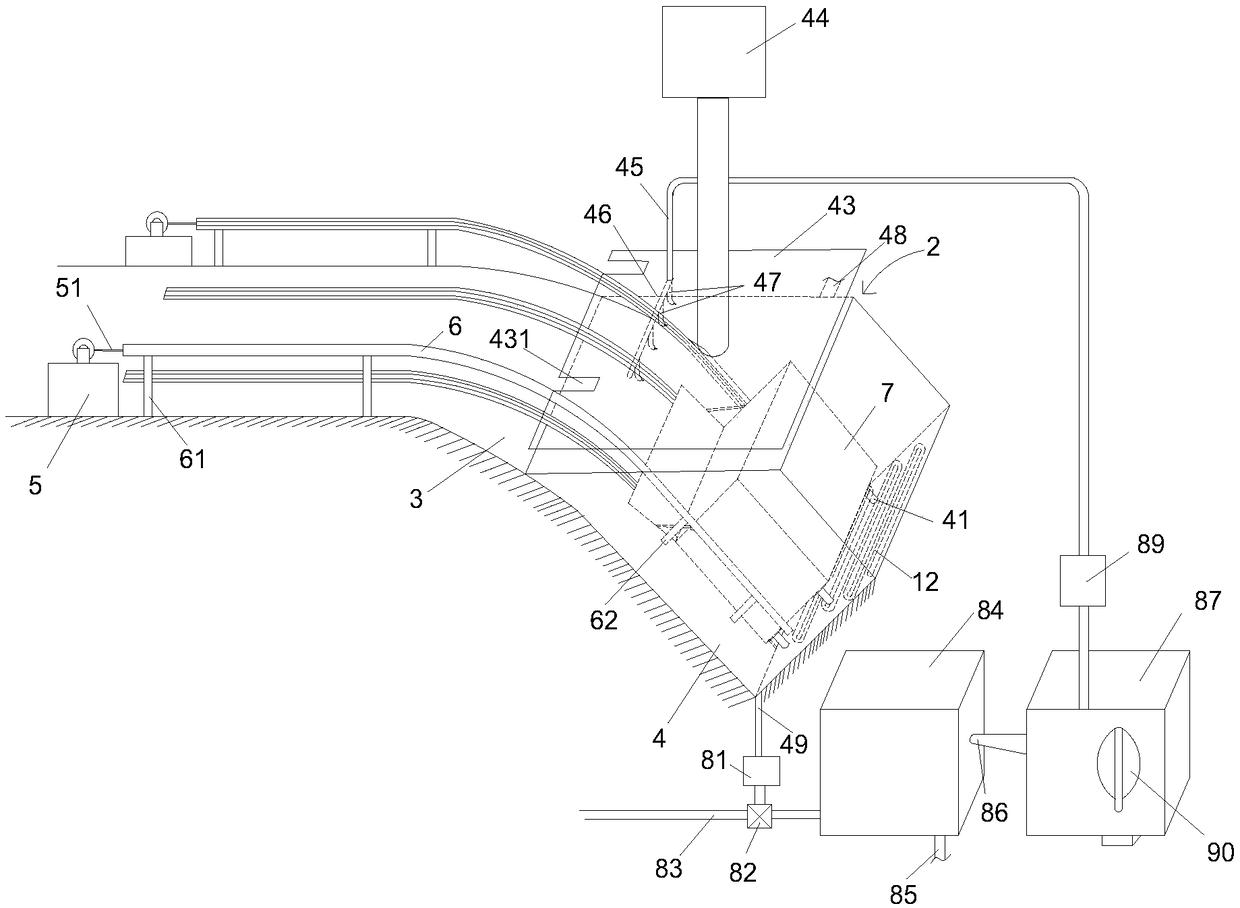

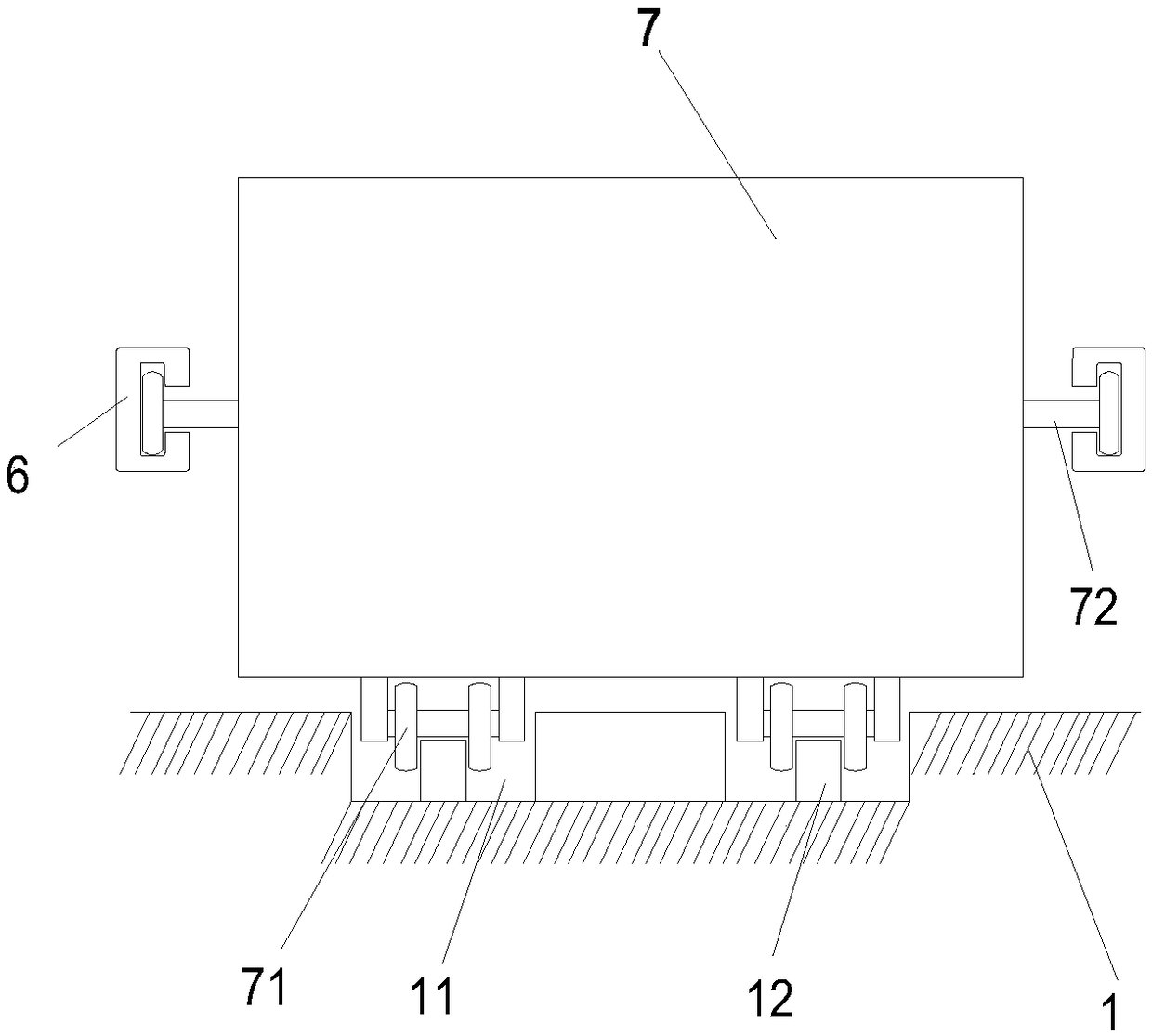

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] see Figure 1 to Figure 4 Shown, a kind of crushed bamboo stewing equipment that is applied to the preparation of bamboo pulp of the present invention comprises a road surface 1 for feeding and discharging and a deep pit 2 arranged at the front end of the road surface 1 for a forklift, and the road surface 1 and the The deep pits 2 are connected by an arc-shaped slope 3; a cooking pool 4 is arranged in the deep pit 2, and the cooking pool 4 is closely attached to the bottom surface of the arc-shaped slope 3; Pipe 40, two hoisting machines 5 are arranged on the road surface 1, and a limit guide rail 6 is arranged in front of the hoist machine 5. Extending into the cooking pool 4, and the limit guide rail 6 is erected on the road surface 1 and the arc-shaped slope 3; two grooves 11 are provided on the road surface 1 and the arc-shaped slope 3, and the grooves 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com