Oil return system of straight expanding ground-source heat pump system with double injectors and oil return method thereof

A technology of ground source heat pumps and ejectors, applied in lighting and heating equipment, compressors, fluid circulation arrangements, etc., can solve the problem of compressor oil return that cannot be solved, cannot fundamentally solve the problem of oil return, and downhole heat exchange Inconvenient manufacturing process and other problems to achieve the effect of ensuring superheat, saving input work, and avoiding liquid hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

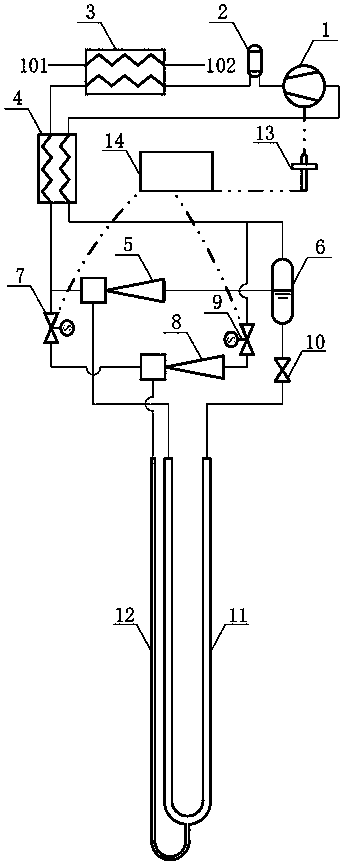

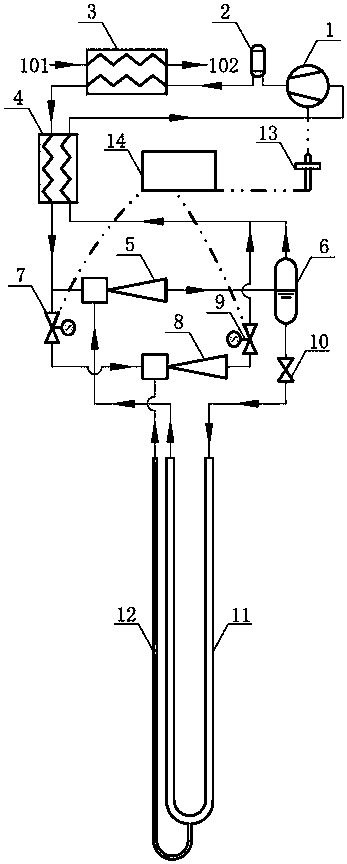

[0034] Such as figure 1 As shown, this embodiment discloses an oil return device for a direct expansion ground source heat pump system with double ejectors, including a compressor 1, an oil separator 2, a condenser / gas cooler 3, an intermediate heat exchanger 4, First injector 5, gas-liquid separator 6, first solenoid valve 7, second injector 8, second solenoid valve 9, throttle valve 10, downhole heat exchanger 11, oil return pipe 12, oil level sensor 13, A controller 14 , a low-temperature brine working fluid outlet 101 , and a high-temperature brine working fluid inlet 102 .

[0035] Wherein, the downhole heat exchanger 11 and the oil return pipe 12 are buried in the underground soil, and the rest of the compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com