Rubber sealing ring compression elasticity modulus testing instrument

A compressive elastic modulus, rubber sealing ring technology, applied in the direction of machine sealing ring testing, application of stable tension/pressure testing material strength, testing of mechanical parts, etc., can solve the economic loss and safety problems of customers and production enterprises , grooves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

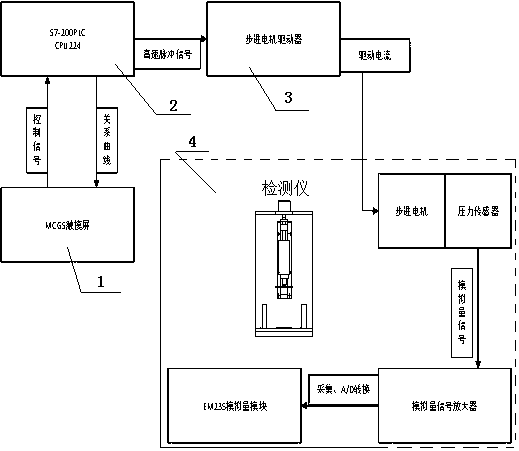

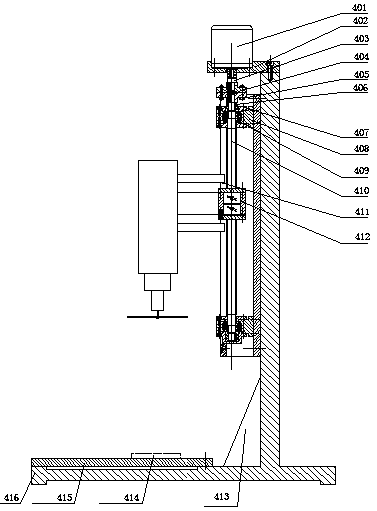

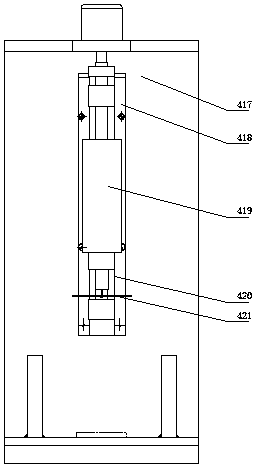

[0021] Such as Figure 1~8 As shown, a rubber sealing ring compression elastic modulus tester designed by the present invention includes a touch screen (1), a PLC controller (2), a stepper motor driver (3) and a detector device (4), and adopts an MT6071IE touch screen ( 1) Control the operation of the PLC program according to the task requirements, for the forward and reverse rotation of the stepping motor, the adjustment of the speed, the limit and the display of the final curve and data, the PLC controller (2) outputs a high-speed pulse signal to the stepping motor driver to control Stepper motor start and forward and reverse, primary speed change and emergency limit. When the contact of the weighing pressure sensor installed on the stepper moto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com