Dish-washing machine

A technology for dishwashers and cabinets, which is applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, cleaning equipment, etc., and can solve problems such as poor cleaning effect and inability to be sprayed , to achieve the effect of reducing the area that cannot be irradiated, reducing the thickness, and reducing the space used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

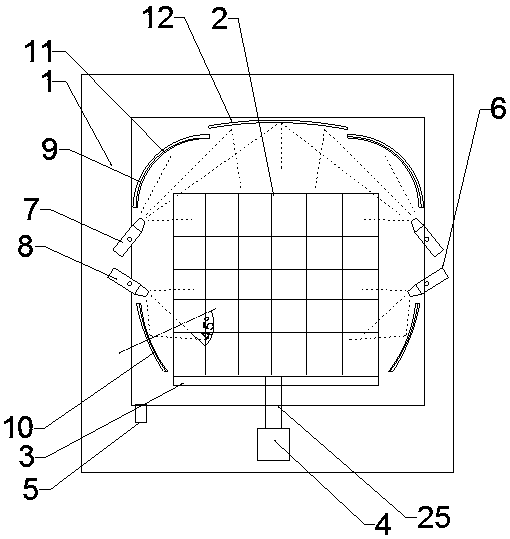

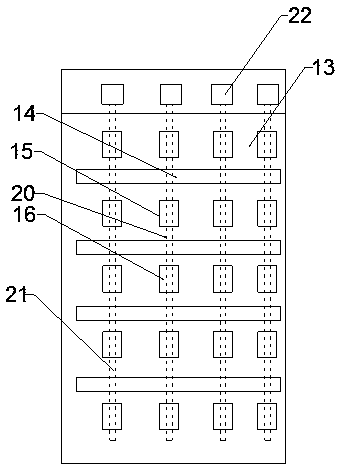

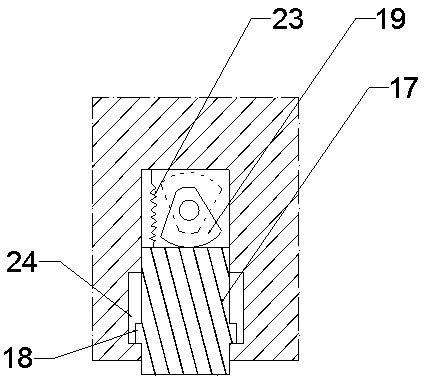

[0032] Such as figure 1 , figure 2 , image 3 As shown, a kind of dishwasher provided by the present invention includes: a casing 1 and a dish rack 2, the dishwasher also includes a base 3, the bowl rack is placed on the base, and the base is driven by a fixed rotating shaft 25 Connect the second drive motor 4 located at the bottom of the case. The bottom of the casing is provided with an outlet pipe 5 . The water outlet pipe is located on the left side of the casing.

[0033] The left and right inner walls of the casing are provided with a pair of oppositely arranged water spray pipe groups 6, and the water spray pipe groups include a first water spray pipe 7 on the upper part and a second water spray pipe 8 on the lower part. The central axis of a water spray pipe is 45° to the vertical line, and the central axis of the second water spray pipe is -45° to the vertical line; the first water spray pipe and the second water spray pipe of the present invention are configured...

Embodiment 2

[0040] A kind of dishwasher provided by the present invention comprises: a casing and a dish rack, and a pair of relatively arranged water spray pipe groups are arranged on the left and right inner walls of the casing, and the water spray pipe groups include a first spray nozzle located on the upper part. The water pipe and the second water spray pipe located at the bottom, the central axis of the first water spray pipe is 45° to the vertical line, and the central axis of the second water spray pipe is -45° to the vertical line;

[0041] A pair of upper side ultraviolet lamps and a pair of lower side ultraviolet lamps are also fixed in the casing, the pair of upper side ultraviolet lamps are respectively located at the left and right corners of the upper part of the bowl rack, and the pair of lower side ultraviolet lamps are respectively located at the bowl rack. At the left and right end corners of the upper part of the frame, the surface of the upper ultraviolet light fixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com