A kind of acupuncture needle production method and acupuncture needle

A production method and technology for acupuncture needles, which are applied in the directions of needles, knitting, and acupuncture, can solve the problems of complex assembly of the needle body and the tube body, low firmness, etc., and achieve the effects of firm combination and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

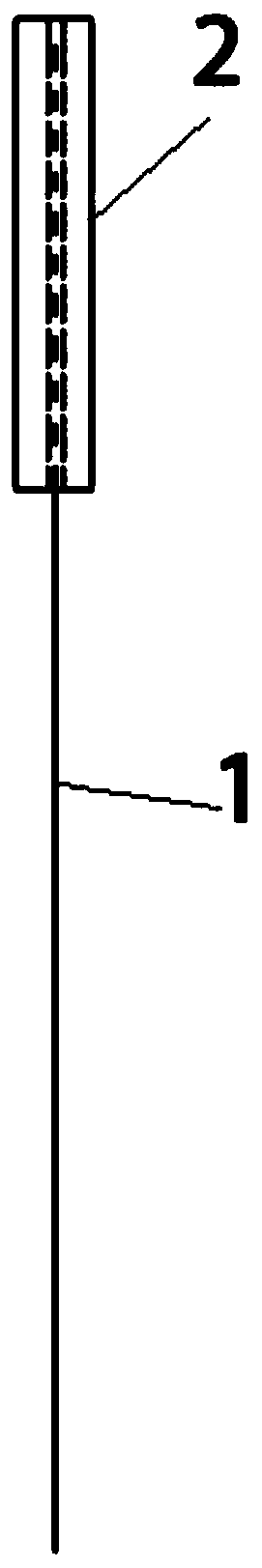

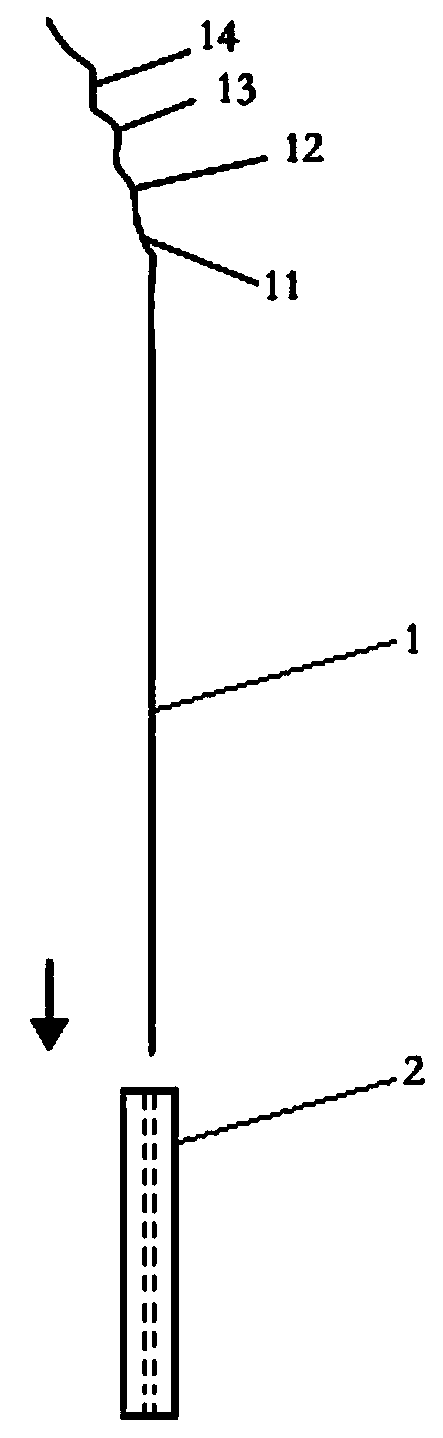

[0038] This embodiment provides an acupuncture needle needle body and tube body assembly method, such as figure 2 shown, including the following steps:

[0039] A method for producing acupuncture needles, comprising the following steps:

[0040] S1: Cut off an aluminum rod according to the required size;

[0041] S2: Open holes in the center of the aluminum rod to form several tubes;

[0042] S3: dye the tube body, the steps of dyeing include:

[0043] S11: Degreasing and cleaning the pipe body;

[0044] S12: Chemically polish the tube body and clean it with clean water;

[0045] S13: Carry out anodic oxidation on the tube body and clean it 7 times;

[0046] S14: coloring the tube body;

[0047] S15: sealing the pipe body, cleaning and drying;

[0048] S4: Take one end of the needle body 1 and process more than 4 folds, such as figure 2 Four folds are shown, first fold 11, second fold 12, third fold 13, fourth fold 14;

[0049] S5: Take a tube body 2 (handle), make ...

Embodiment 2

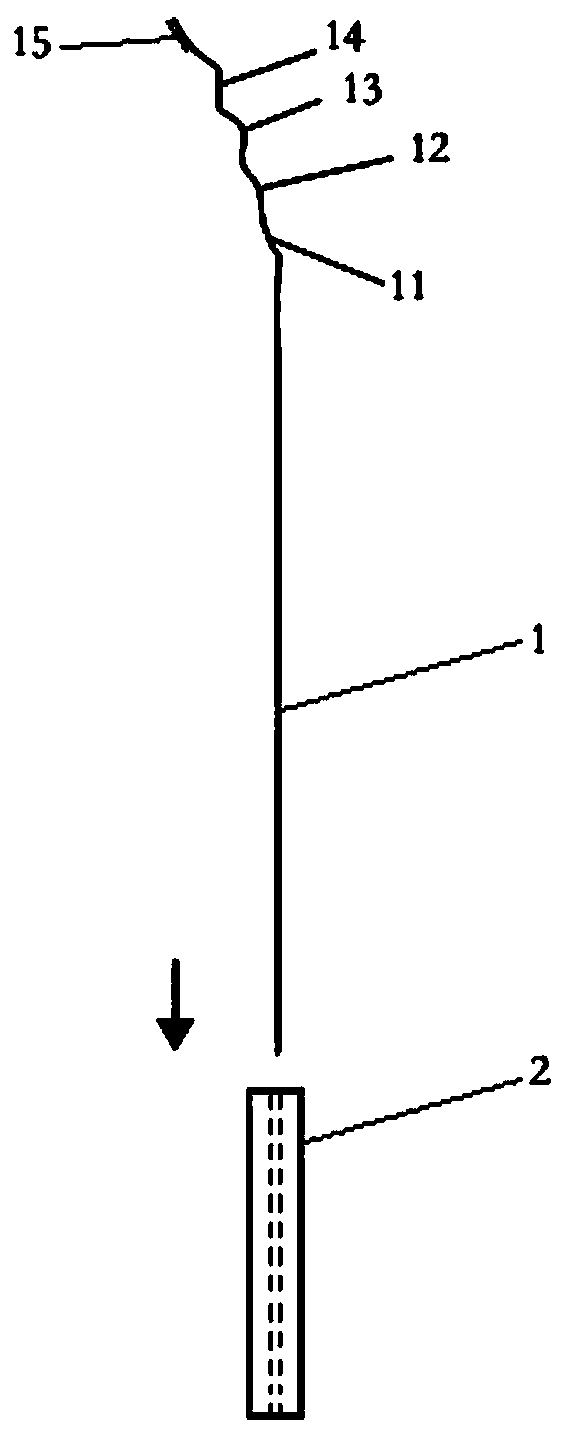

[0059] The present embodiment provides a method for assembling an acupuncture needle body and a tube body, comprising the following steps:

[0060] S1: Cut off an aluminum rod according to the required size;

[0061] S2: Open holes in the center of the aluminum rod to form several tubes;

[0062] S3: dye the tube body, the steps of dyeing include:

[0063] S11: Degreasing and cleaning the pipe body;

[0064] S12: Chemically polish the tube body and clean it with clean water;

[0065] S13: Carry out anodic oxidation on the tube body and clean it 7 times;

[0066] S14: coloring the tube body;

[0067] S15: sealing the pipe body, cleaning and drying;

[0068] S4: Take a needle body 1, and process more than 4 folds at one end of the needle body 1 (the folds are inclined in one direction);

[0069] S5: bending the end of the fold part of the needle body 1 by 180° to form an overlapping part;

[0070]S6: Take a tube body 2, make the other end of the needle body 1 pass through...

Embodiment 3

[0082] This embodiment provides an acupuncture needle prepared by the acupuncture needle preparation method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com