Tail gas treatment apparatus for thermal power generation

A technology for exhaust gas treatment and treatment box, which is applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of plants unable to obtain nutrients, loss of minerals, withering, etc., to improve work effect, ensure environmental protection, and improve contact The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

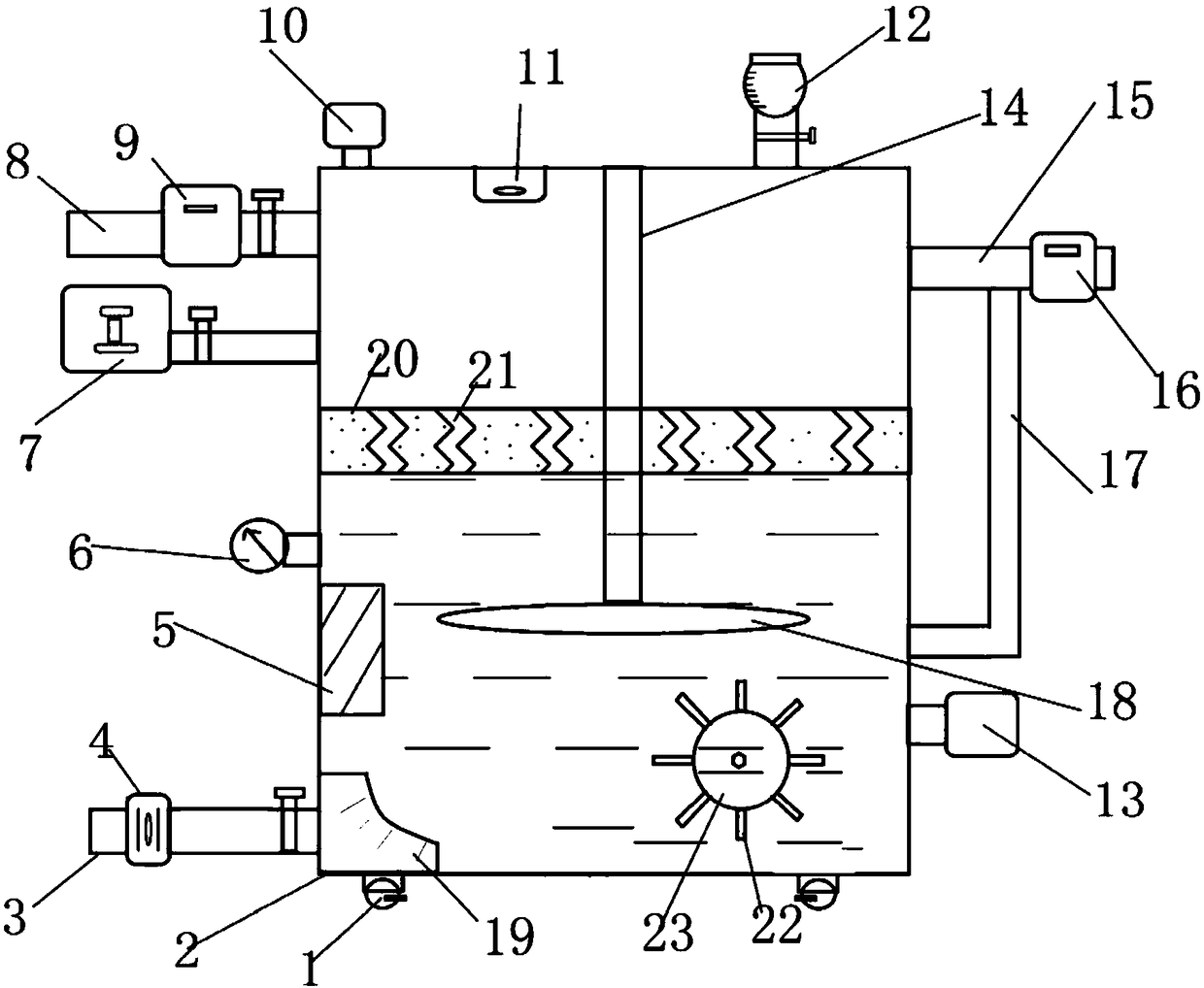

[0012] see figure 1 , a thermal power generation tail gas treatment device, comprising a guide wheel 1, a treatment box 2, an intake pipe 3, an air pump 4, a heater 5, a pressurizing device 7, a water inlet pipe 8, a camera 11, an additive burette 12, a pH tester 13, Rotating shaft 14, air outlet pipe 15, gas detection device 16, return pipe 17 and impeller 18, described processing box 2 bottom surface is provided with guide wheel 1, is provided with handbrake on guide wheel 1, and guide wheel 1 facilitates device to move, saves time and effort , the air intake pipe 3 communicates with the treatment box 2, and the joint between the air intake pipe 3 and the treatment box 2 is provided with a spiral air inlet 19, through which the tail gas is conveniently spiraled into the treatment box 2, slows down its rising speed, and is convenient Its full con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com