Accurate material mixing device for chemical fertilizer production

An accurate and fertilizer technology, applied in mixer accessories, transportation and packaging, chemical instruments and methods, etc., can solve problems such as poor controllability and inaccurate proportioning, and achieve accurate proportioning, low labor cost, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

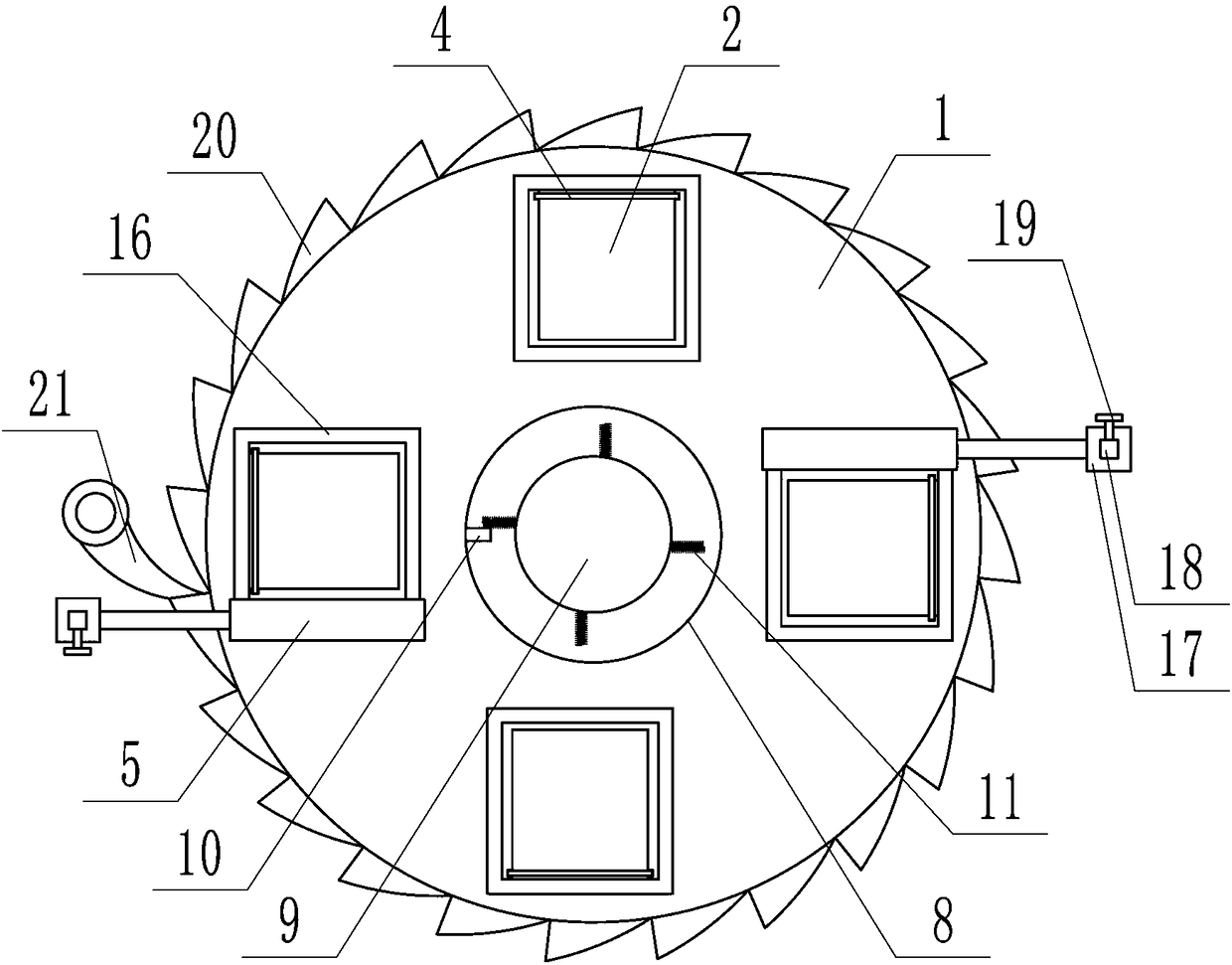

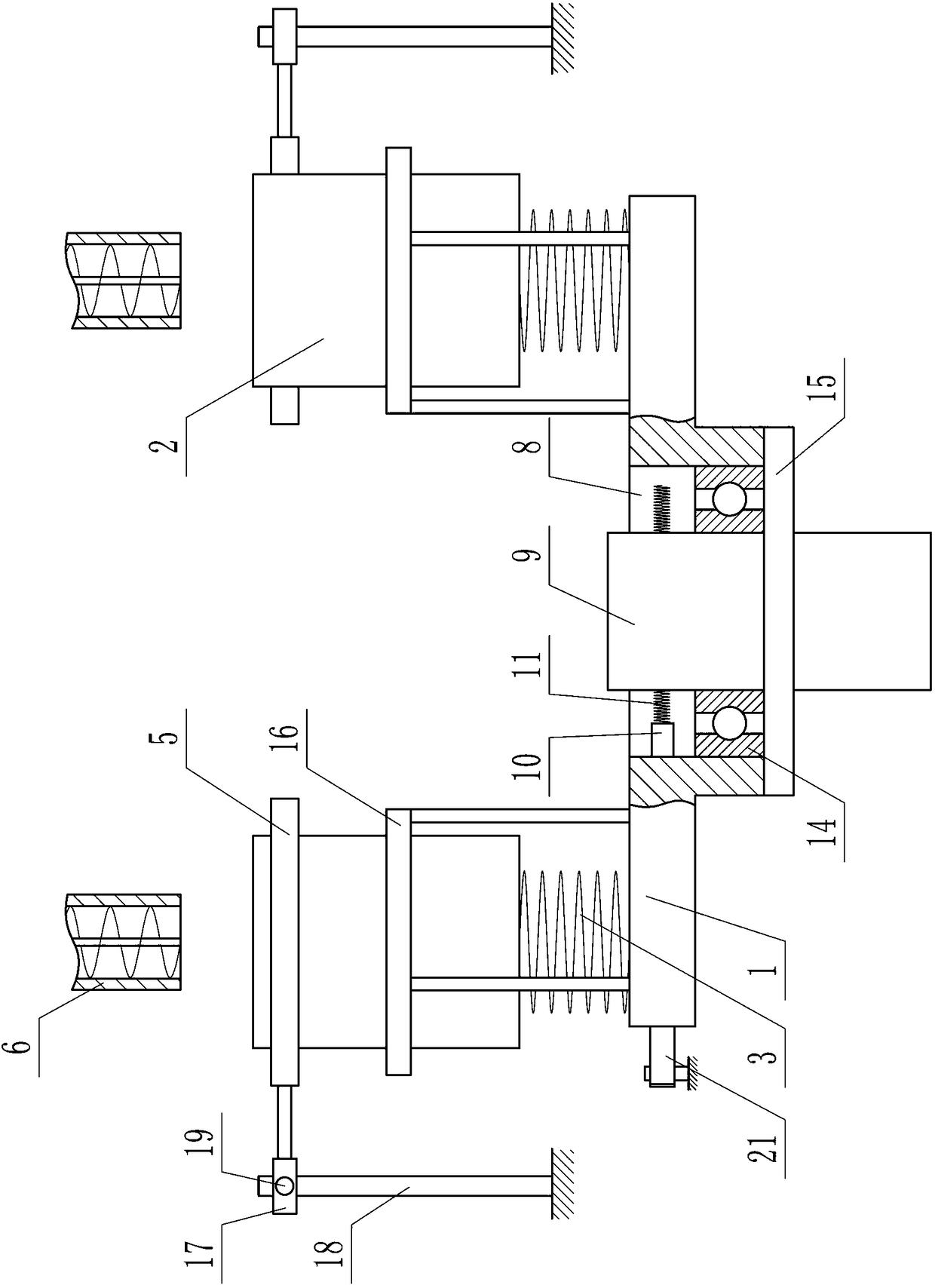

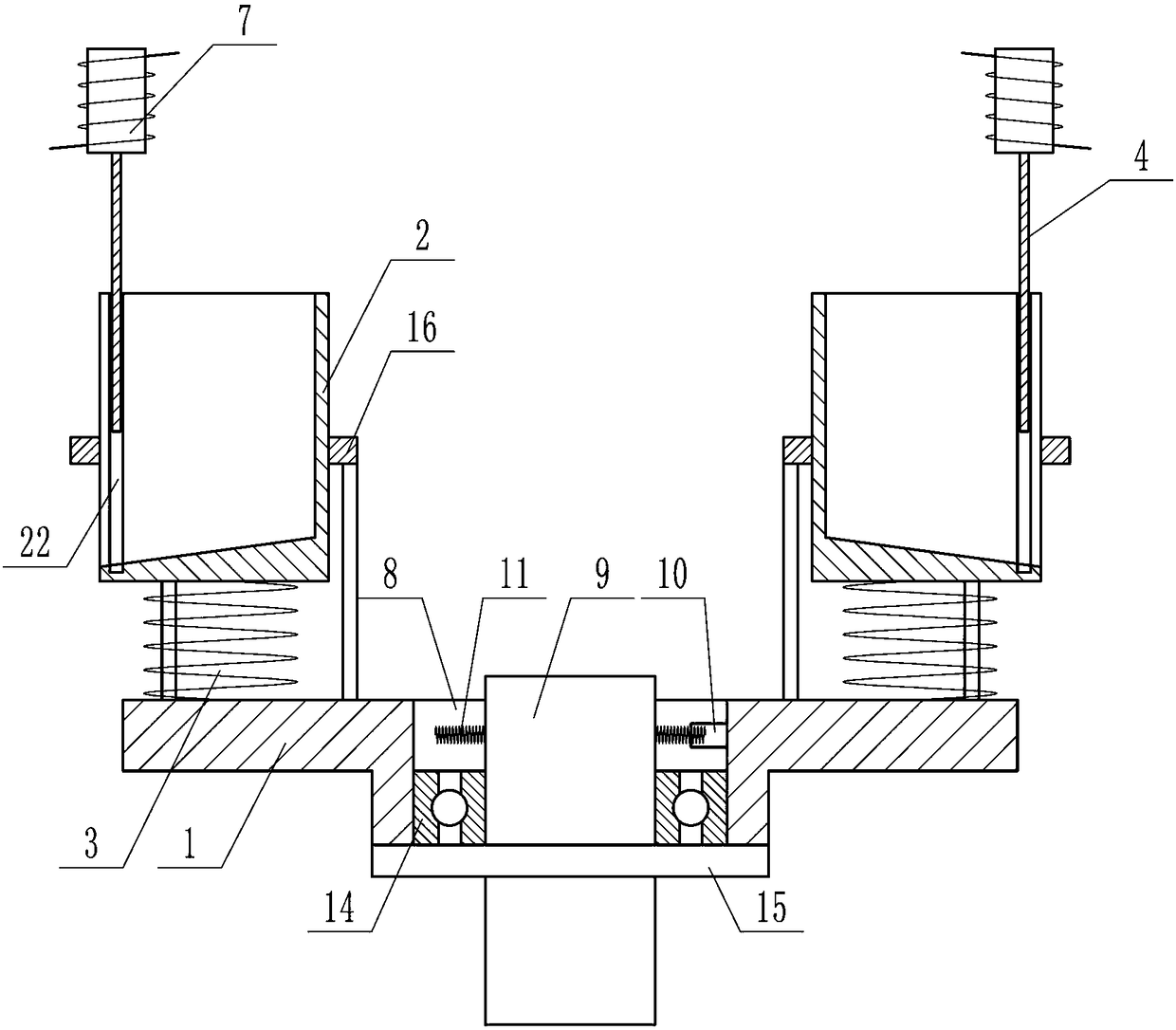

[0014] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] Depend on Figure 1 to Figure 6 Given, the present invention comprises a horizontally placed and rotatable disc 1, four vertical and open upper-end receiving barrels 2 are installed on the upper surface of the disc 1, the four receiving barrels 2 are evenly distributed around the circumference, and four A compression spring 3 is respectively connected between the lower end of the receiving barrel 2 and the disc 1, and the four receiving barrels 2 can rotate synchronously with the disc 1 and can move up and down respectively, and the outward side plate of the receiving barrel 2 is a The pumping plate 4 that can be twitched up and down, the pumping plate 4 is a magnetic material, the pumping plate 4 slides up and down to realize the opening and closing of the side of the receiving barrel 2; two horizontal stop rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com