Preparation technology of environment-friendly aluminum foil packaging material

A packaging material and an environment-friendly technology, applied in the technical field of the preparation of environment-friendly aluminum foil packaging materials, can solve the problems of insufficient product performance stability, low production efficiency, poor tensile resistance, etc., so as to reduce the labor and production of adhesives. High efficiency and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

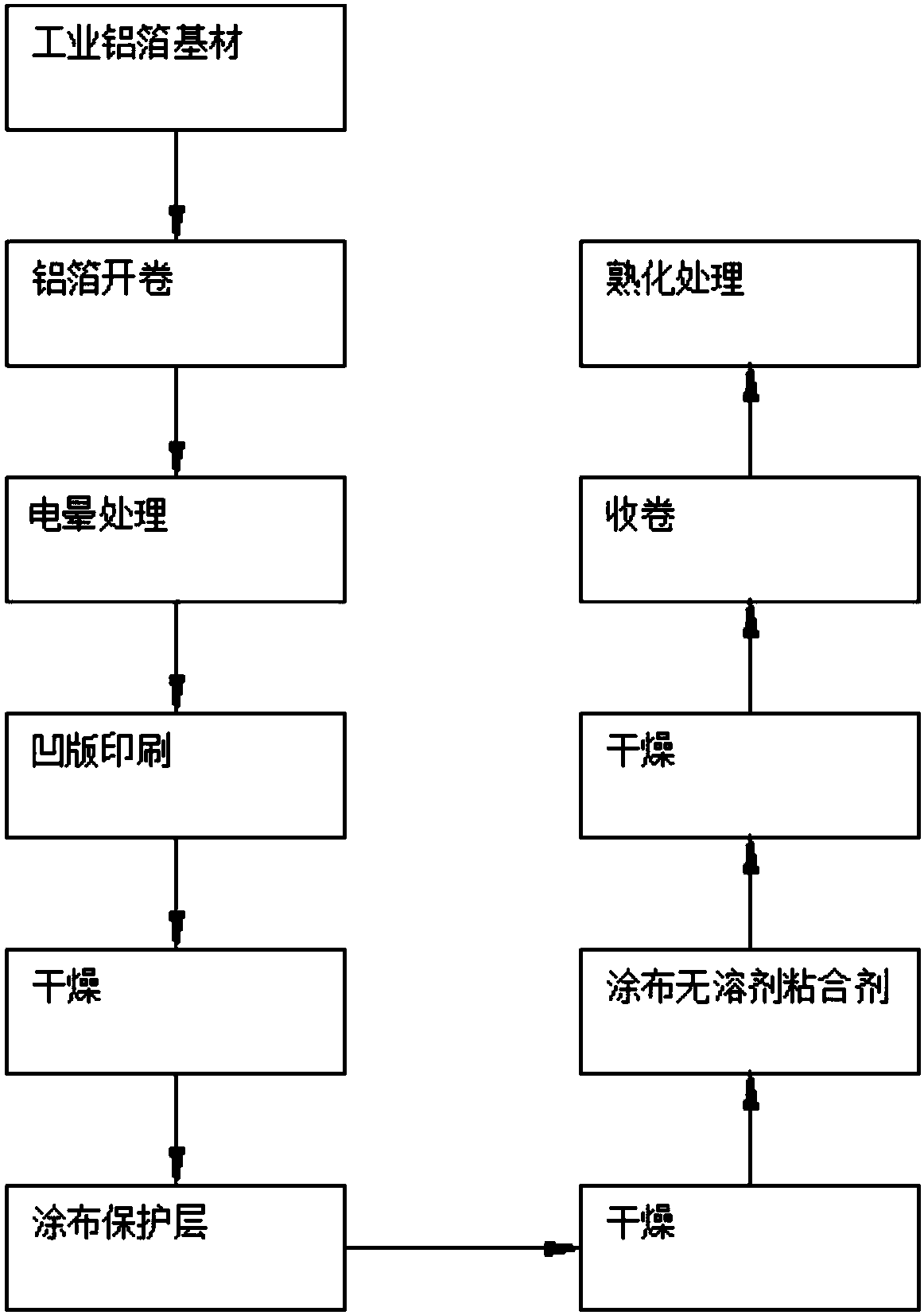

[0027] A preparation technology for an environment-friendly aluminum foil packaging material, comprising the following preparation steps:

[0028] Step 1: Select industrial aluminum foil as the base material, and unwind the aluminum foil;

[0029] Step 2: Carrying out corona treatment to the unrolled industrial aluminum foil described in step 1;

[0030] Step 3: gravure printing the corona-treated aluminum foil on a printing and coating machine, and the printing and coating machine runs at a speed of 55 m / min;

[0031] Step 4: Dry the aluminum foil after gravure printing. During the drying process, the temperature of the aluminum foil in the drying tunnel is controlled at 165°C;

[0032] Step 5: Coat the dried aluminum foil with a protective layer, and the coating thickness is controlled at 3.5mm;

[0033] Step 6: The aluminum foil coated with the protective layer is dried again, and the coating temperature is 38°C;

[0034] Step 7: Apply a solvent-free adhesive to the alum...

Embodiment 2

[0039] A preparation technology for an environment-friendly aluminum foil packaging material, comprising the following preparation steps:

[0040] Step 1: Select industrial aluminum foil as the base material, and unwind the aluminum foil;

[0041] Step 2: Carrying out corona treatment to the unrolled industrial aluminum foil described in step 1;

[0042] Step 3: gravure printing the corona-treated aluminum foil on a printing-coating machine, and the printing-coating machine runs at a speed of 105 m / min;

[0043] Step 4: Dry the gravure-printed aluminum foil. During the drying process, the temperature of the aluminum foil in the drying tunnel is controlled at 188°C;

[0044] Step 5: Coat the dried aluminum foil with a protective layer, and the thickness of the coating is controlled at 5.3 mm;

[0045] Step 6: The aluminum foil coated with the protective layer is dried again, and the coating temperature is 42°C;

[0046] Step 7: Apply a solvent-free adhesive to the aluminum f...

Embodiment 3

[0051] A preparation technology for an environment-friendly aluminum foil packaging material, comprising the following preparation steps:

[0052] Step 1: Select industrial aluminum foil as the base material, and unwind the aluminum foil;

[0053] Step 2: Carrying out corona treatment to the unrolled industrial aluminum foil described in step 1;

[0054] Step 3: gravure printing the corona-treated aluminum foil on a printing and coating machine, and the printing and coating machine runs at a speed of 155m / min;

[0055] Step 4: Dry the aluminum foil after gravure printing. During the drying process, the temperature of the aluminum foil in the drying tunnel is controlled at 210°C;

[0056] Step 5: Coat the dried aluminum foil with a protective layer, and control the thickness of the coating to 7.0mm;

[0057] Step 6: The aluminum foil coated with the protective layer is dried again, and the coating temperature is 46°C;

[0058] Step 7: Apply a solvent-free adhesive to the alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com