Full-automatic multi-station forging hydraulic press

A hydraulic press and multi-station technology, applied in the field of hydraulic presses and forging hydraulic presses, can solve the problems of lower forging temperature, affecting production efficiency, unfavorable forging process completion and forging quality, etc., so as to reduce the temperature drop of forgings, improve production efficiency, and improve forging. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

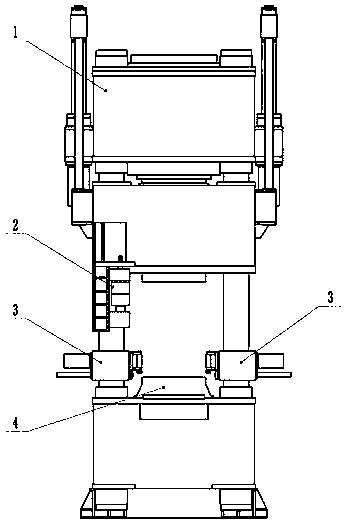

[0029] see figure 1 , the present invention mainly includes: a host machine 1, a swing mold frame 2, a moving manipulator 3, and a mobile workbench 4. The main machine 1 is a four-column hydraulic machine body; the swing mold frame 2 is installed on the slider of the main machine 1; there are two transfer manipulators 3, which are respectively installed on the left and right sides of the main machine 1; The mobile workbench 4 is installed on the workbench of the main machine 1 and supported by guide rails, can move forward and backward, and is driven by a hydraulic cylinder.

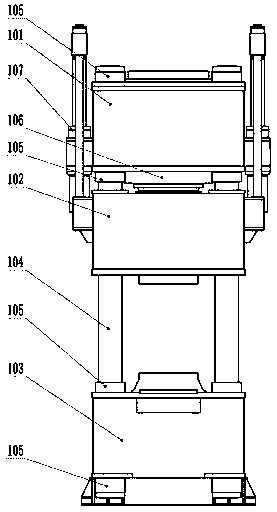

[0030] see figure 2 , the main engine 1 of the present invention is a four-column hydraulic press body composed of an upper beam 101, a slide block 102, a workbench 103, a column 104, a nut 105, a master cylinder 106, and a return cylinder 107.

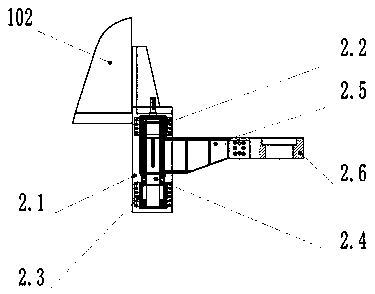

[0031] see image 3 The swing formwork 2 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com