Grinding area adjustable stone mill for bridge construction

A bridge construction and adjustable technology, applied in grinding machines, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to reduce dust, non-adjustable grinding area, low grinding efficiency, etc., to achieve the effect of enhancing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

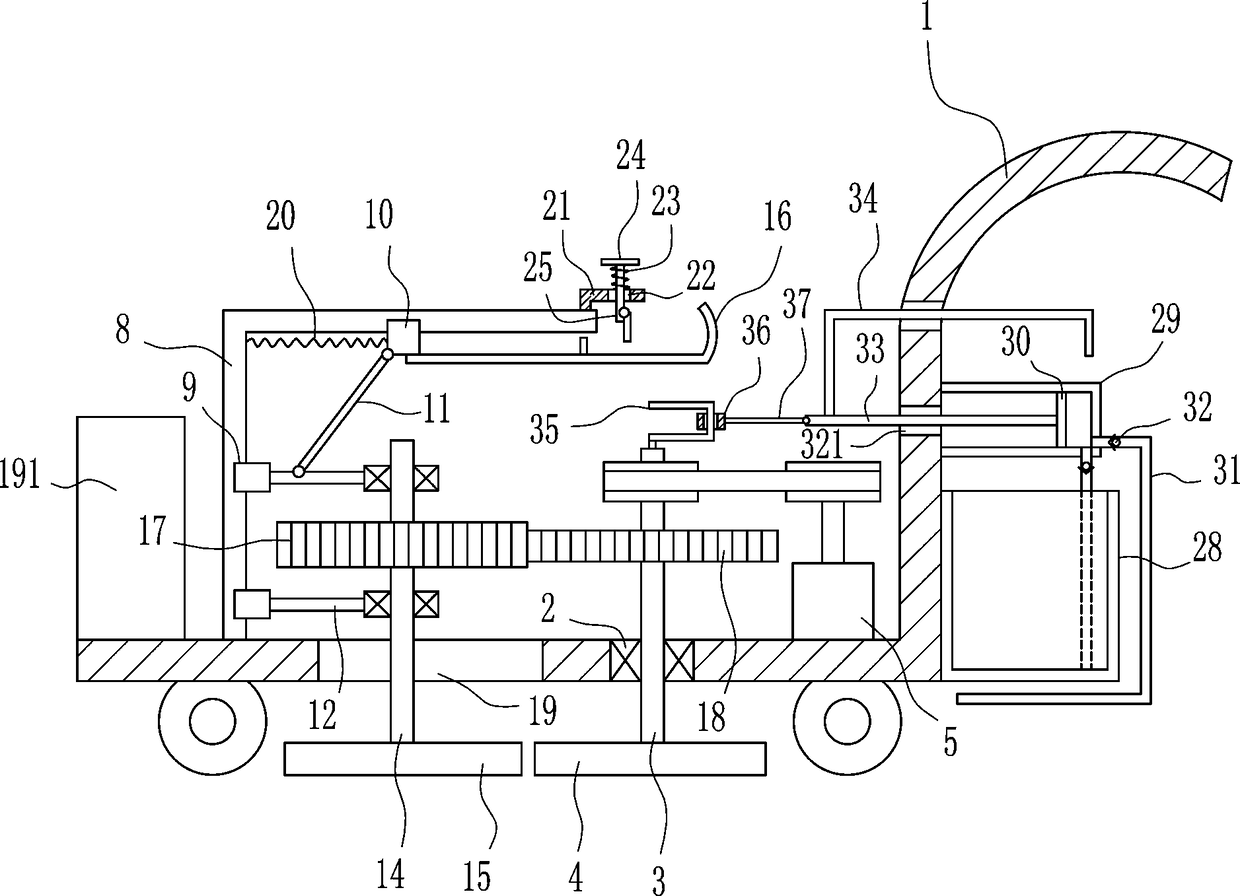

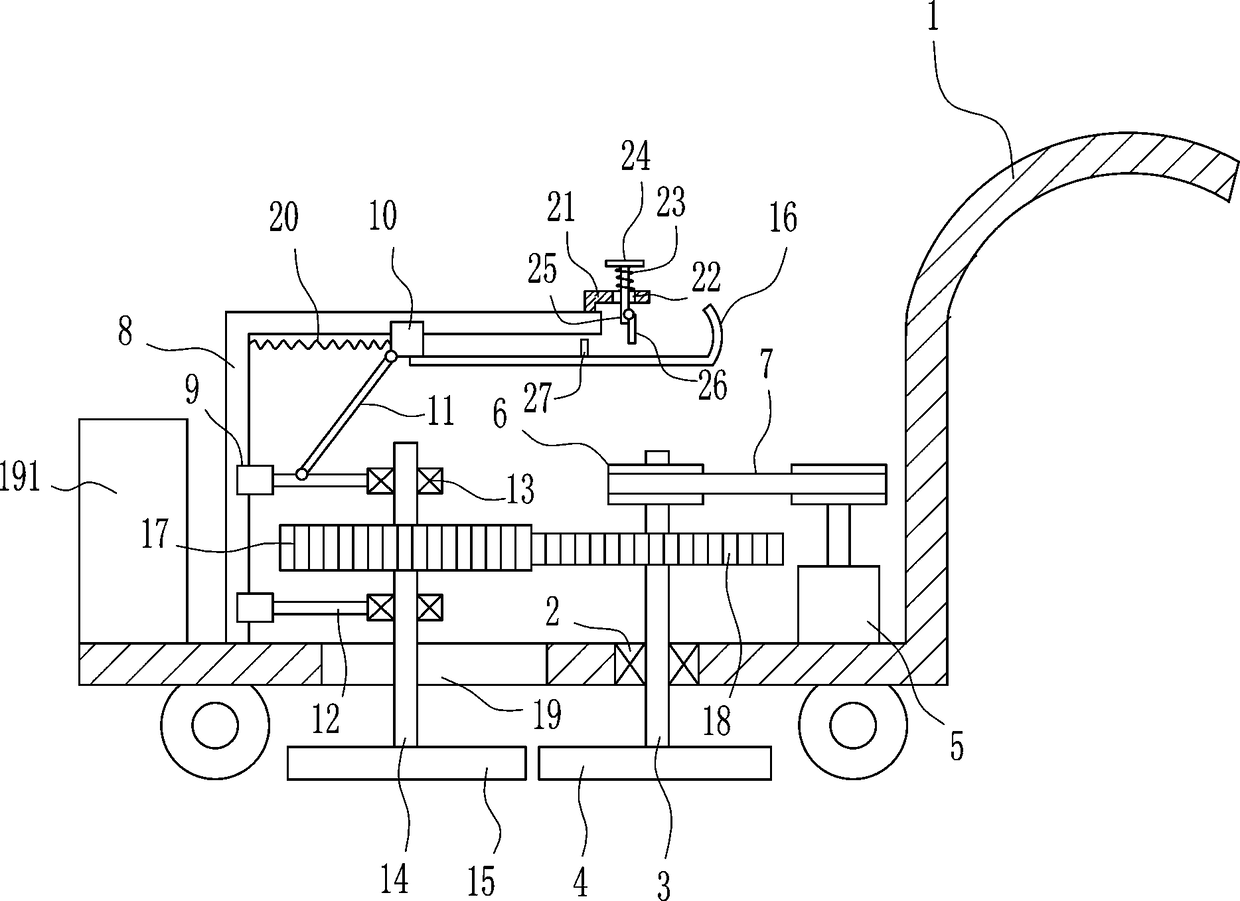

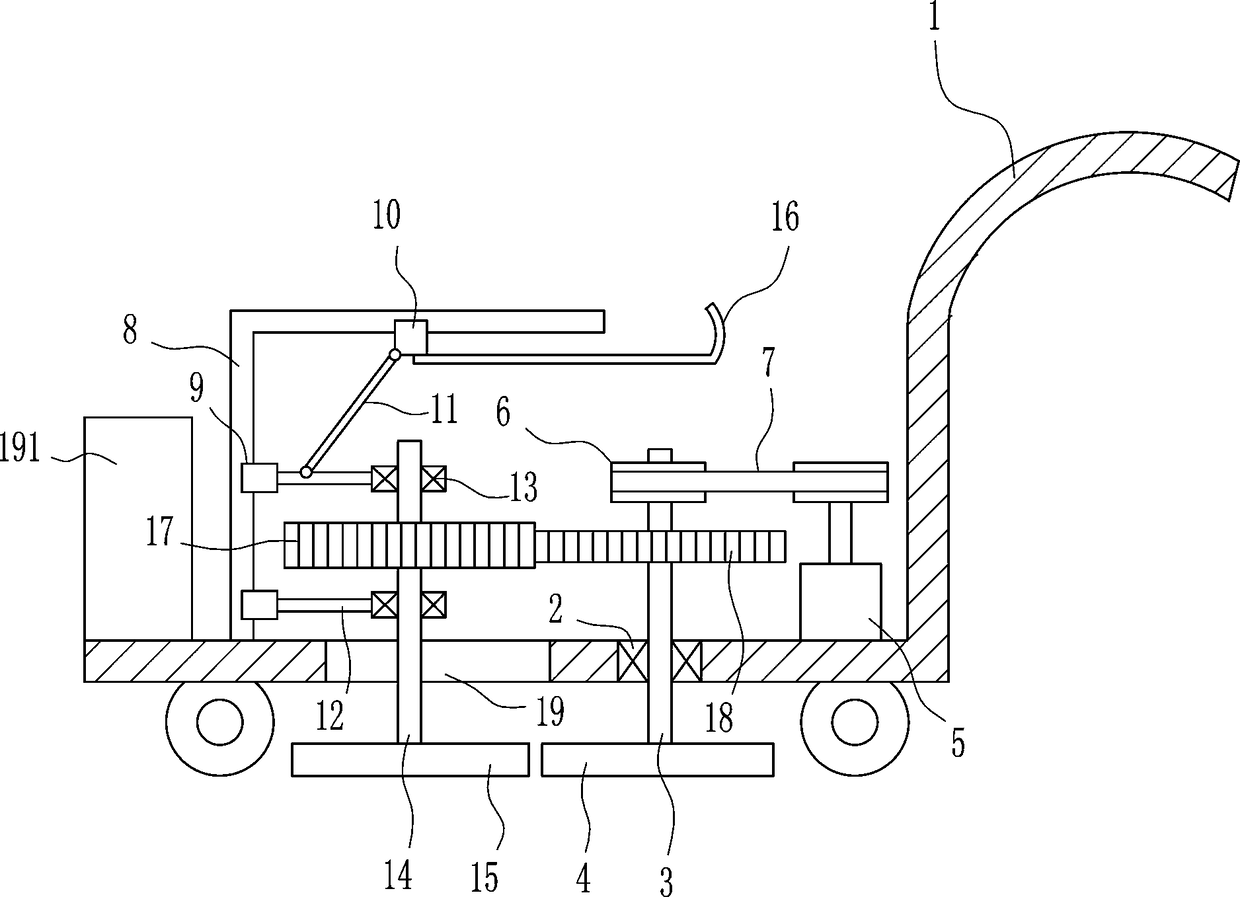

[0028] A kind of grinding area adjustable grinding stone machine for bridge construction, such as Figure 1-5 As shown, it includes a cart 1, a first bearing seat 2, a first rotating rod 3, a first grindstone 4, a motor 5, a pulley 6, a flat belt 7, an L-shaped slide rail 8, a first slider 9, a first Two slide blocks 10, connecting rod 11, the first mounting plate 12, the second bearing seat 13, the second rotating rod 14, the second grinding stone 15, the left and right moving rod 16, the first gear 17, the second gear 18 and the accumulator 191 , the right part of the lower side of the trolley 1 is embedded with the first bearing seat 2, the first bearing seat 2 is connected with the first rotating rod 3, the lower end of the first rotating rod 3 is provided with the first grinding stone 4, and the cart 1 The right part of the side is provided with a motor 5, and the motor 5 is located on the right side of the first rotating rod 3, and a belt pulley 6 is arranged on the outp...

Embodiment 2

[0030] A kind of grinding area adjustable grinding stone machine for bridge construction, such as Figure 1-5 As shown, it includes a cart 1, a first bearing seat 2, a first rotating rod 3, a first grindstone 4, a motor 5, a pulley 6, a flat belt 7, an L-shaped slide rail 8, a first slider 9, a first Two slide blocks 10, connecting rod 11, the first mounting plate 12, the second bearing seat 13, the second rotating rod 14, the second grinding stone 15, the left and right moving rod 16, the first gear 17, the second gear 18 and the accumulator 191 , the right part of the lower side of the trolley 1 is embedded with the first bearing seat 2, the first bearing seat 2 is connected with the first rotating rod 3, the lower end of the first rotating rod 3 is provided with the first grinding stone 4, and the cart 1 The right part of the side is provided with a motor 5, and the motor 5 is located on the right side of the first rotating rod 3, and a belt pulley 6 is arranged on the outp...

Embodiment 3

[0033] A kind of grinding area adjustable grinding stone machine for bridge construction, such as Figure 1-5 As shown, it includes a cart 1, a first bearing seat 2, a first rotating rod 3, a first grindstone 4, a motor 5, a pulley 6, a flat belt 7, an L-shaped slide rail 8, a first slider 9, a first Two slide blocks 10, connecting rod 11, the first mounting plate 12, the second bearing seat 13, the second rotating rod 14, the second grinding stone 15, the left and right moving rod 16, the first gear 17, the second gear 18 and the accumulator 191 , the right part of the lower side of the trolley 1 is embedded with the first bearing seat 2, the first bearing seat 2 is connected with the first rotating rod 3, the lower end of the first rotating rod 3 is provided with the first grinding stone 4, and the cart 1 The right part of the side is provided with a motor 5, and the motor 5 is located on the right side of the first rotating rod 3, and a belt pulley 6 is arranged on the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com