Construction brick recycling device

A technology for building and processing boxes, which is applied in the directions of grinding/polishing safety devices, grinding machine parts, grinding feed movement, etc. It can solve the problem of low efficiency in recycling old bricks and reduce the possibility of brick breakage , saving time and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

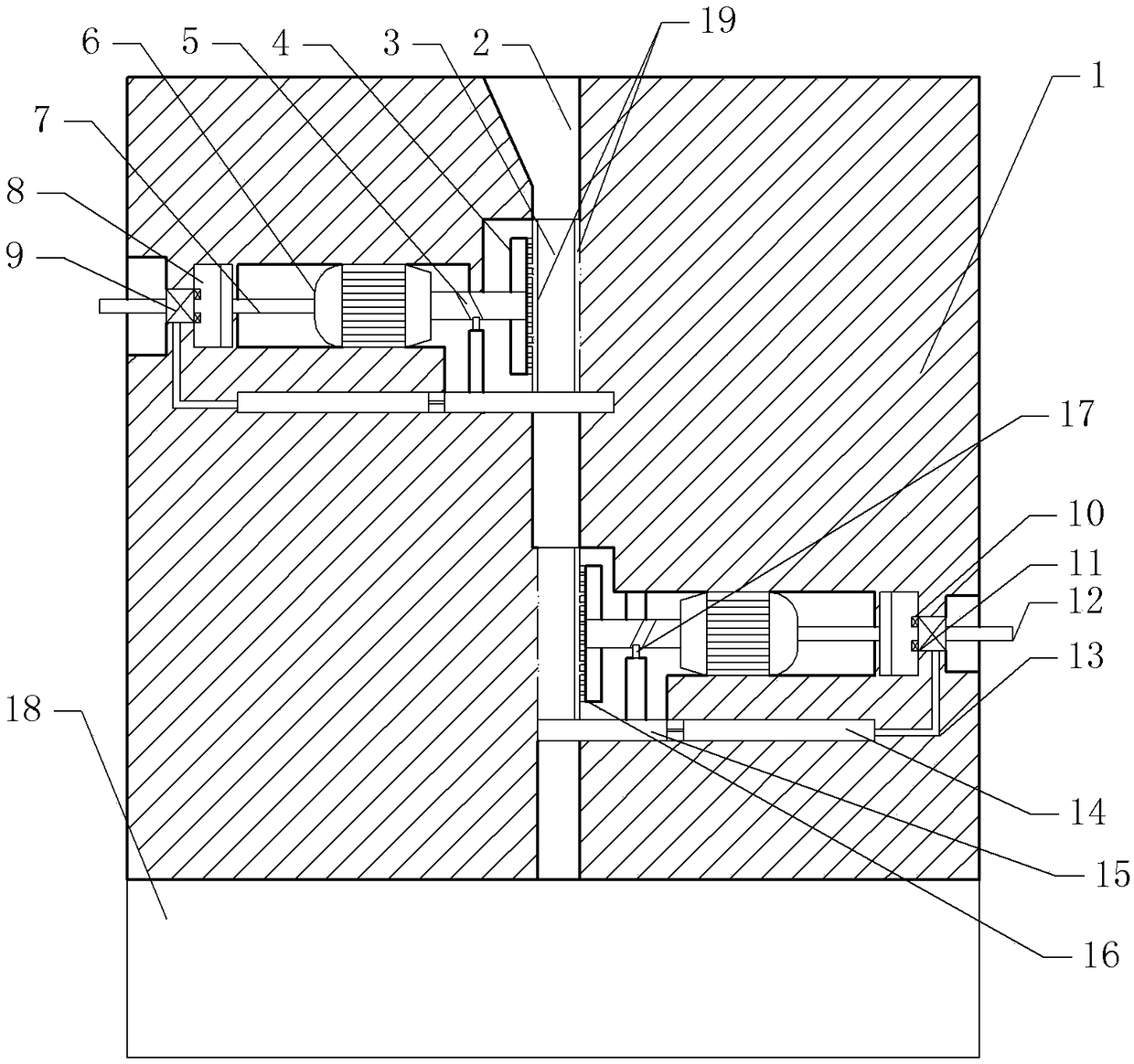

[0024] as attached figure 1 As shown, a device for recycling building bricks includes a processing box 1, which is provided with a feeding channel 2 that runs through the processing box 1 from top to bottom, and the upper opening of the feeding channel 2 is flared. The left side of the upper part of the feeding channel 2 is provided with a first processing mechanism, and the right side of the lower part of the feeding channel 2 is provided with a second processing mechanism, and the cross section of the upper part of the feeding channel 2 is greater than that of the lower part.

[0025] Both the first processing mechanism and the second processing mechanism include a motor 6, a processing disc 4 and a protrusion 16, the motor 6 is horizontally slidably connected with the processing box 1, the drive shaft of the motor 6 is provided with a chute 5, and a drive shaft is provided below the drive shaft. The baffle plate and the projection 17 fixed on the baffle plate, the projectio...

Embodiment approach

[0028] The specific implementation is as follows:

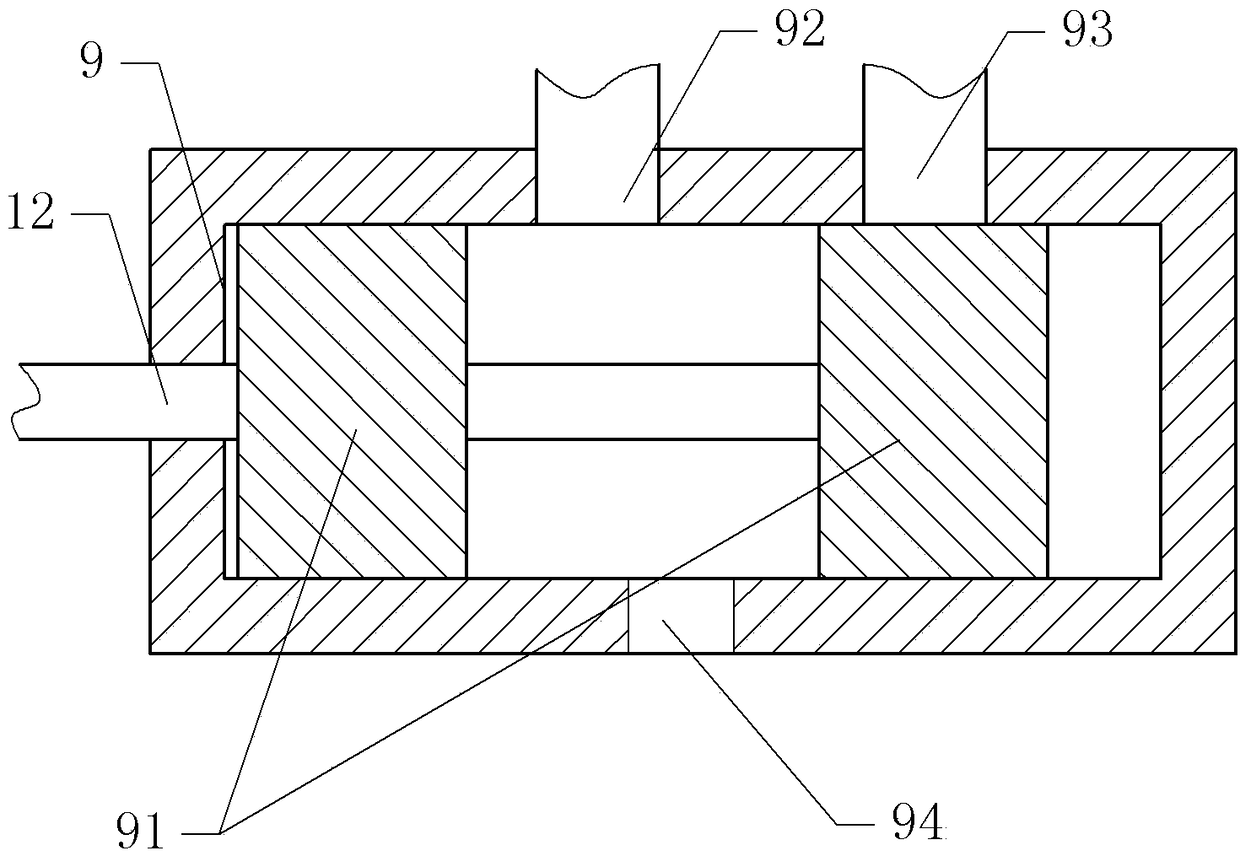

[0029] Turn on the motors 6 of the first processing mechanism and the second processing mechanism, and activate the reversing valve on the left, push the reversing shaft 12 and make the left slider 91 close the first valve port 92, so that the air outlet check valve 11 communicates with the intake port 94 through the second valve port 93 .

[0030] When the motor 6 of the first processing mechanism works, the motor 6 will drive the drive shaft to rotate, and the drive shaft will drive the processing disc 4 and the protrusion 16 to rotate. When the drive shaft rotates, under the action of the chute 5 and the projection 17, the motor 6 can slide horizontally on the processing box 1. When the motor 6 slides to the air chamber 8, the motor 6 will push the piston rod 7 and push the piston plate through the piston rod 7, and the piston plate will pass the gas in the air chamber 8 through the second valve port 93 and the air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com