Variable stiffness soft robot system

A robotic system and variable stiffness technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as low load-bearing capacity and insufficient material stiffness, and achieve the effects of enhancing load-bearing capacity, expanding the application range, and enhancing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

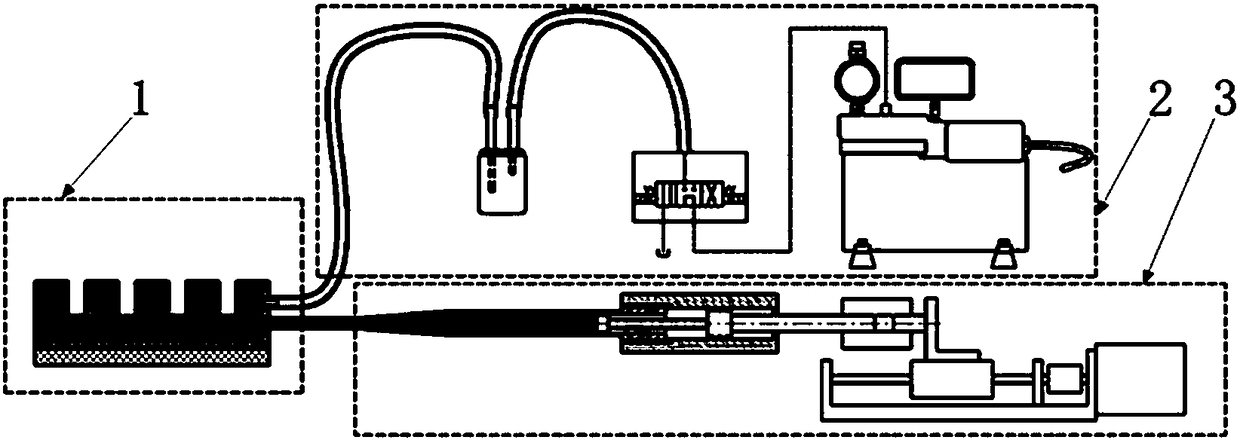

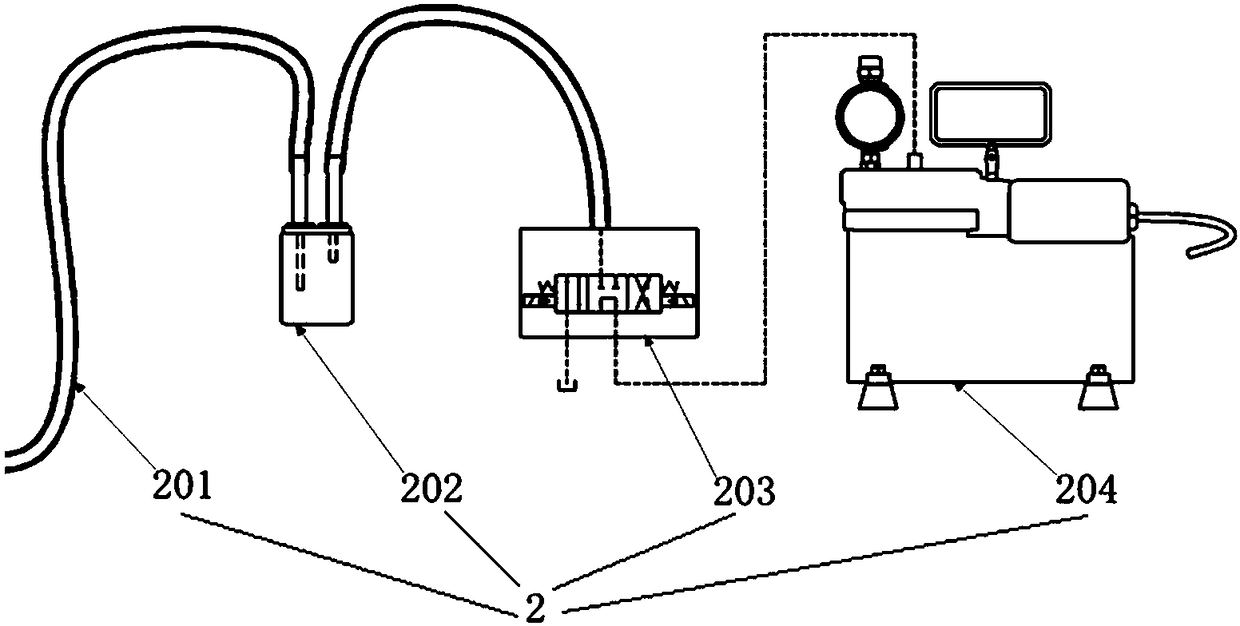

[0035] see figure 1 , a variable stiffness soft robot system in the illustration is the preferred solution of the present invention, specifically including a soft robot 1 capable of deformation, a vacuum pumping device 2 for vacuuming the inner cavity of the soft robot, Particle delivery device 3 for delivery of deformable medium.

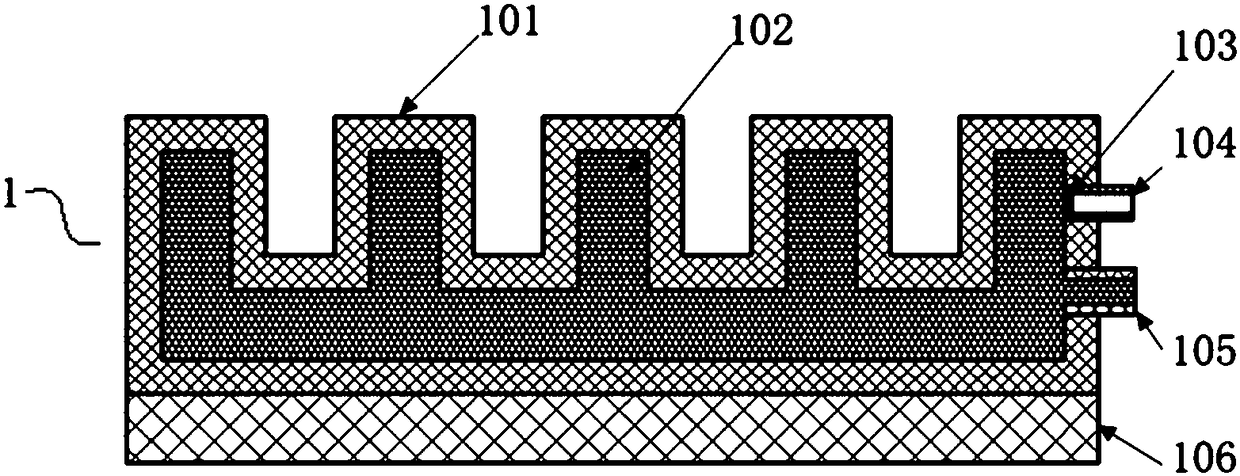

[0036] Specific as figure 2 As shown, the soft robot can realize the bending action, and is mainly composed of an elastically deformable cavity wall 101, a cavity 102 and a backing 106, wherein the elastically deformable cavity wall 101 is made of silicon rubber with a relatively low modulus of elasticity, and the backing 106 It is arranged in close contact with the outer wall of the elastic deformation cavity wall 101 along the axial direction, and is made of PP with a relatively high elastic modulus, so as to reduce the axial elongation of the soft robot and provide the main restoring force for the soft robot.

[0037] The cavity 102 is surrou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com