An environmentally friendly flame-retardant adhesive-free particle board for crop straw and preparation method thereof

A crop straw and particle board technology, which is applied to flat products, other household utensils, wood processing appliances, etc., can solve the problems that hinder the popularization and application of interior decoration materials, lack of strong adhesion of synthetic resin, and no flame retardant effect. Achieve low price, strong resistance and killing effect, and improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

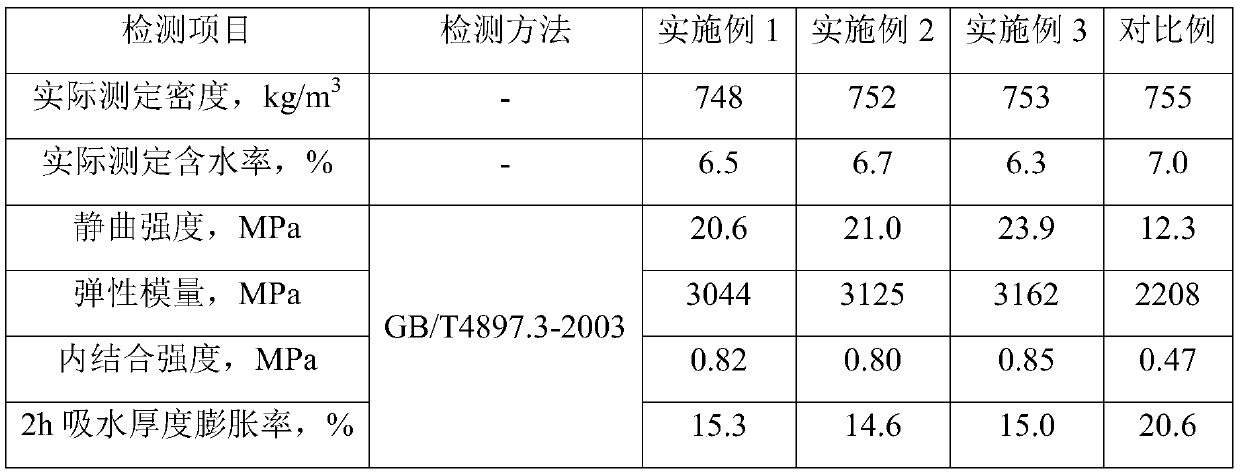

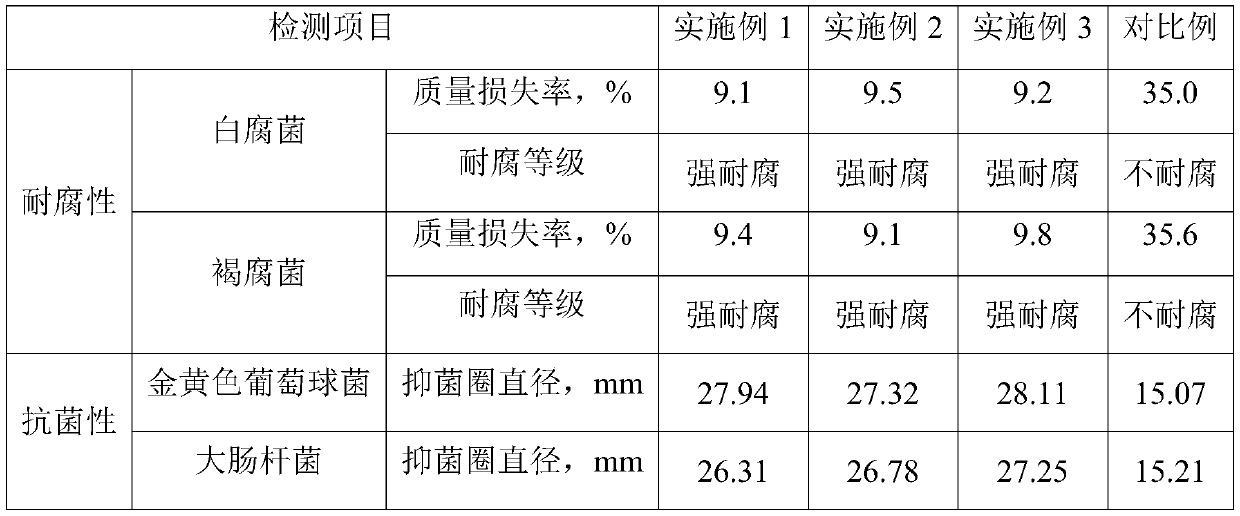

Embodiment 1

[0042] The crop straw environment-friendly flame-retardant adhesive-free particle board of this embodiment is prepared by the following method:

[0043] 1) Take dried wheat straw and crush it to below 3.0mm and sieve it to obtain coarse wheat straw with a particle diameter of 0.5-3.0mm and fine wheat straw with a particle diameter below 0.5mm; the fine wheat straw accounts for 20% of the total weight of the crushed wheat straw , the balance is wheat straw coarse material;

[0044] Take the dried sorghum stalks and crush them to less than 3.0 mm and sieve them to obtain coarse sorghum material with a particle size of 0.5-3.0 mm and fine sorghum material with a particle size of less than 0.5 mm; the fine sorghum material accounts for 20% of the total weight of the crushed sorghum stalk , and the balance is sorghum coarse material;

[0045] 2) After mixing nano-calcium carbonate, nano-zinc oxide and nano-copper oxide according to the mass ratio of 2.5:0.3:0.2, add them to the si...

Embodiment 2

[0053] The crop straw environment-friendly flame-retardant adhesive-free particle board of this embodiment is prepared by the following method:

[0054] 1) Take the dried wheat straw and grind it below 3.0 mm and sieve it to obtain coarse wheat straw with a particle diameter of 0.5-3.0 mm and fine wheat straw with a particle diameter below 0.5 mm; the fine wheat straw accounts for 23% of the total weight of the crushed wheat straw , the balance is wheat straw coarse material;

[0055] Take dried sorghum stalks and crush them to less than 3.0 mm and sieve them to obtain coarse sorghum materials with a particle size of 0.5-3.0 mm and fine sorghum materials with a particle size of less than 0.5 mm; fine sorghum materials account for 23% of the total weight of the crushed sorghum stalks , and the balance is sorghum coarse material;

[0056] 2) After mixing nano-calcium carbonate, nano-zinc oxide and nano-copper oxide according to the mass ratio of 2.5:0.35:0.15, add them to the s...

Embodiment 3

[0064] The crop straw environment-friendly flame-retardant adhesive-free particle board of this embodiment is prepared by the following method:

[0065] 1) Take dried wheat straw and crush it to below 3.0mm and sieve it to obtain coarse wheat straw with a particle diameter of 0.5-3.0mm and fine wheat straw with a particle diameter below 0.5mm; the fine wheat straw accounts for 25% of the total weight of the crushed wheat straw , the balance is wheat straw coarse material;

[0066] Take dried sorghum stalks and crush them to less than 3.0 mm and sieve them to obtain coarse sorghum material with a particle size of 0.5-3.0 mm and fine sorghum material with a particle size of less than 0.5 mm; the fine sorghum material accounts for 25% of the total weight of the crushed sorghum stalk material , and the balance is sorghum coarse material;

[0067] 2) After mixing nano-calcium carbonate, nano-zinc oxide and nano-copper oxide according to the mass ratio of 2.5:0.4:0.1, add them to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com