Patents

Literature

32results about How to "Long-term anti-corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

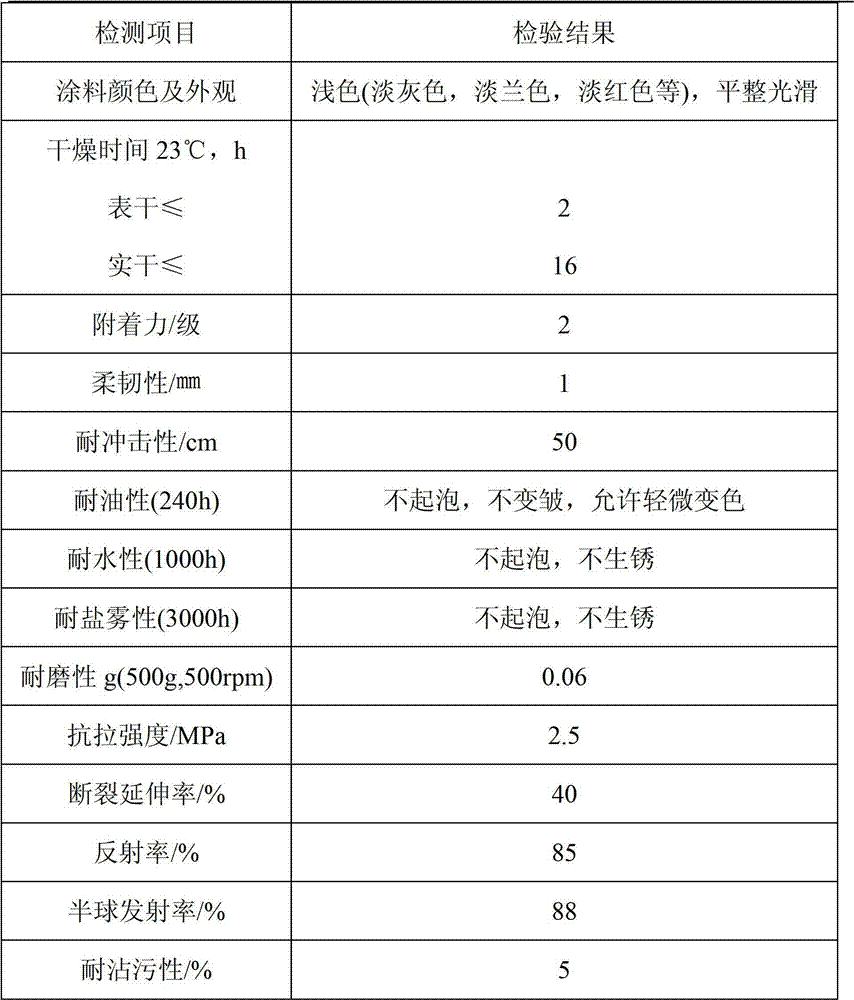

Heat reflection type epoxy anti-corrosion coating

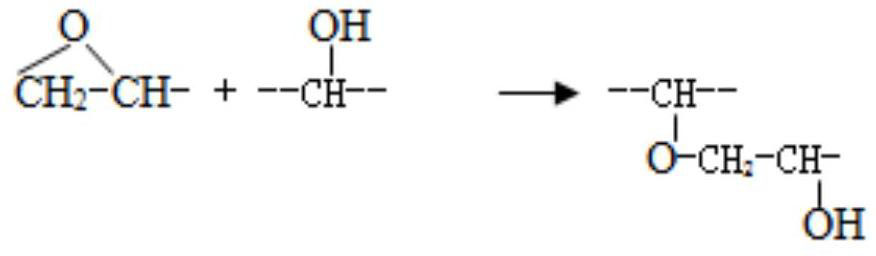

InactiveCN102888176ALong-term anti-corrosionSave resourcesAnti-corrosive paintsEpoxy resin coatingsCoating systemSolvent free

The invention aims to provide a heat reflection type epoxy anti-corrosion coating. The heat reflection type epoxy anti-corrosion coating comprises the following components in percentage by weight: 25 to 35 percent of bisphenol A epoxy resin (E51), 10 to 15 percent of reactive diluent, 5 to 10 percent of titanium dioxide, 5 to 10 percent of hollow glass microsphere, 3 to 5 percent of infrared radiation powder, 10 to 24 percent of barium sulfate filler, 0.3 to 1.0 percent of rheological aid, 0.2 to 0.5 percent of dispersing agent and 15 to 25 percent of curing agent. Compared with the prior art, the anti-corrosion coating has the advantages that a solvent-free heavy-duty anti-corrosion coating system is adopted, so that environment can be improved, resources can be saved, cost can be reduced, economic benefit can be improved, the protection time can be prolonged to reach 15 years, and the coating is withy applying; and the coating can prevent corrosion, also has the functions of heat insulation and reflection, and is suitable for protecting the surface of steel, particularly the surfaces of open-air metal storage tanks and bunkers, so that the aim is fulfilled.

Owner:SHANGHAI DATONG TABERNACLE NEW ENERGY SAVING MATERIALS CO LTD

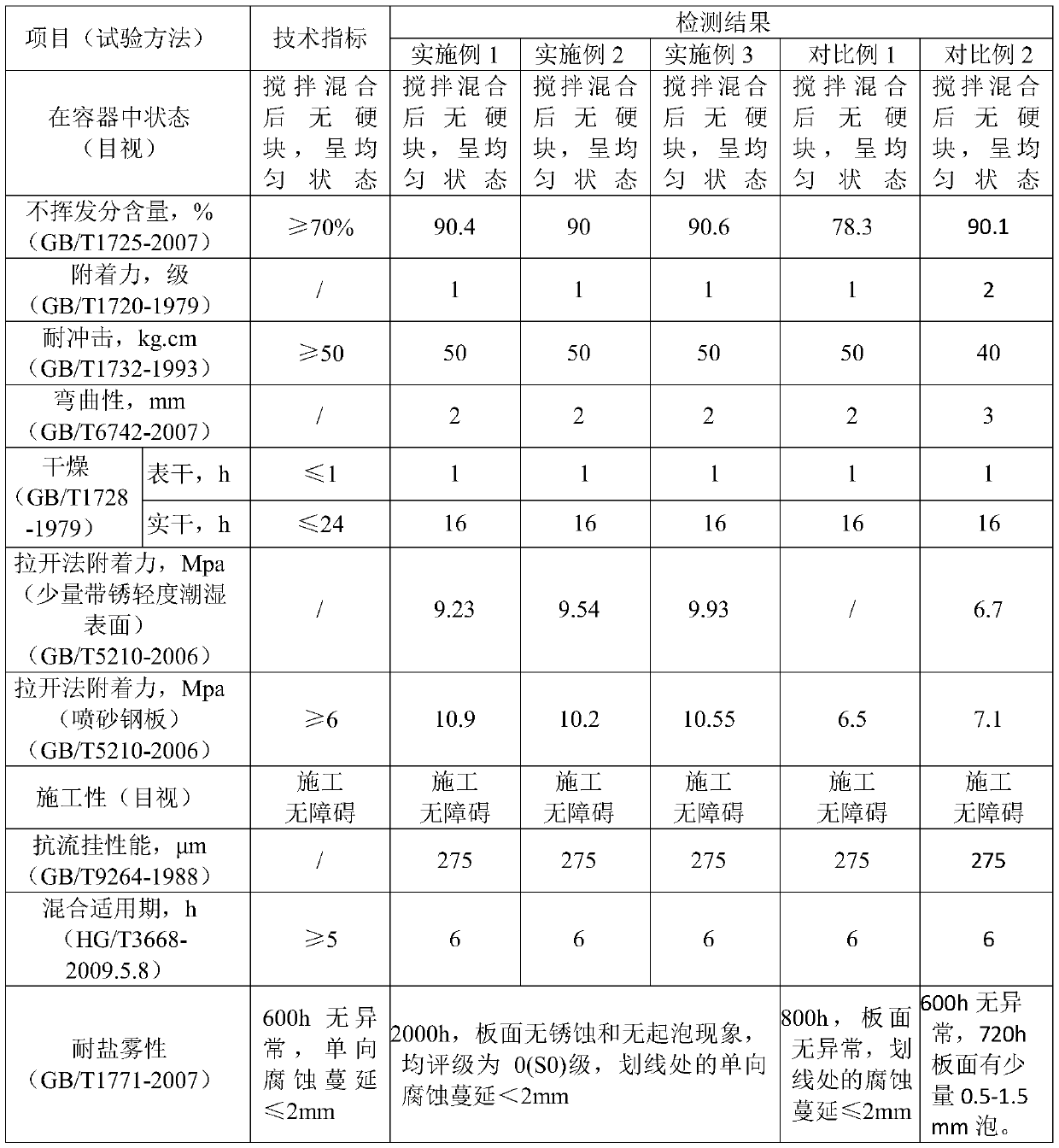

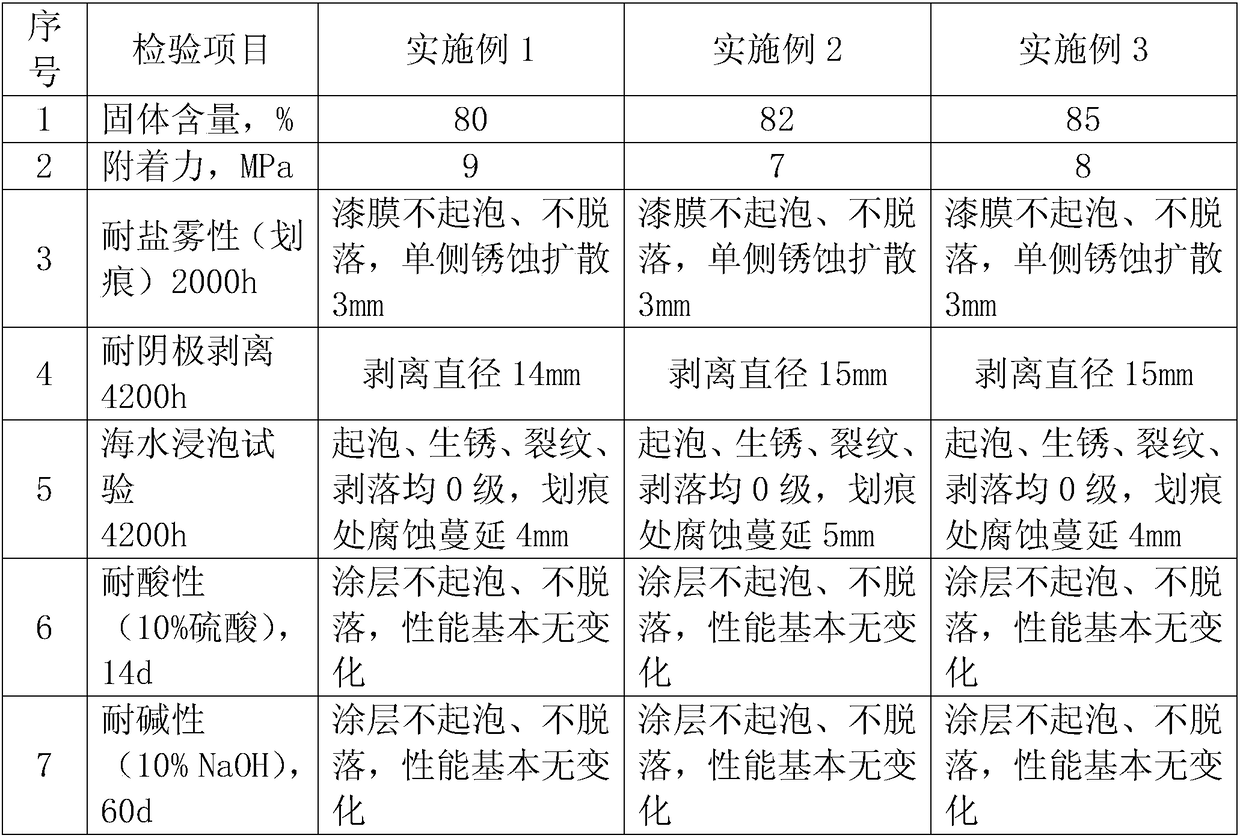

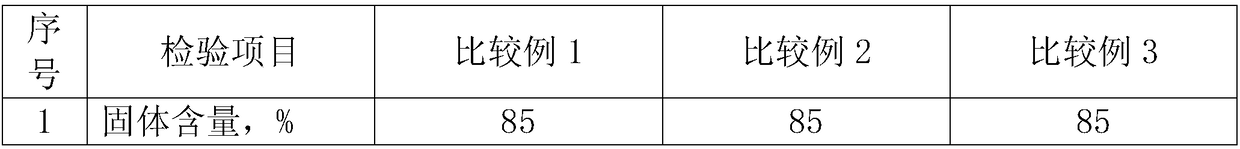

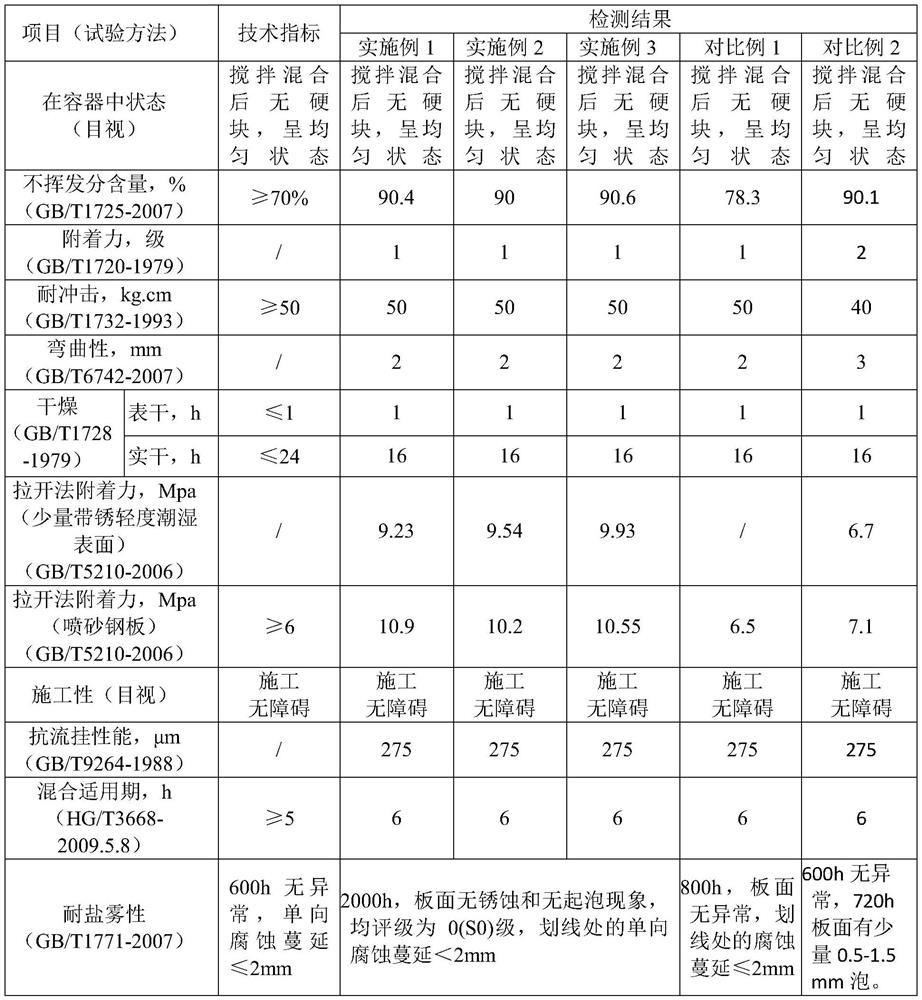

High-solid surface-tolerant epoxy zinc-rich primer and preparation method and application thereof

ActiveCN110144160AIncrease crosslink densityImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemical industryEpoxy

The invention relates to a high-solid surface-tolerant epoxy zinc-rich primer. The primer is prepared from a component A and a component B according to a weight ratio of (16-20):1; the component A comprises the following components in parts by weight: 5-9 parts of liquid phenolic epoxy resin, 6-15 parts of E20 solid epoxy resin, 0.5-1.5 parts of an active diluent, 0.1-0.3 part of a dispersing agent, 70-80 parts of main rust-proof pigment, 2-6 parts of chemical anti-rust pigment, 1.5-2.5 parts of an anti-settling agent and 3-4 parts of an organic mixed solvent; and the component B comprises thefollowing components in parts by weight: 1.5-2.5 parts of a polyamide curing agent, 2-3 parts of a Mannich base curing agent, 0.3-0.6 part of a silane coupling agent and 0.2-0.6 part of an organic mixed solvent. The invention also relates to a preparation method of the primer and a coating film. The primer is high in solid content and low in VOC content, is resistant to corrosion, has a long effect, has good adhesive force and salt fog resistance, and is particularly suitable for repairing and maintaining equipment in industries such as chemical industry, thermoelectricity, machinery and thelike.

Owner:江阴市大阪涂料有限公司

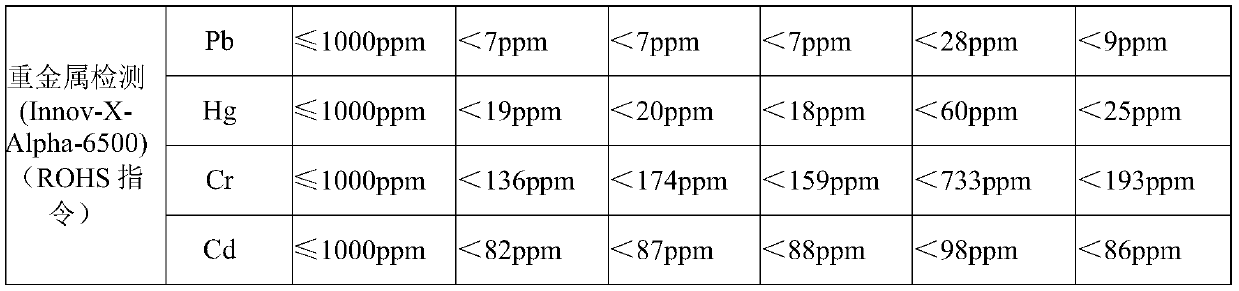

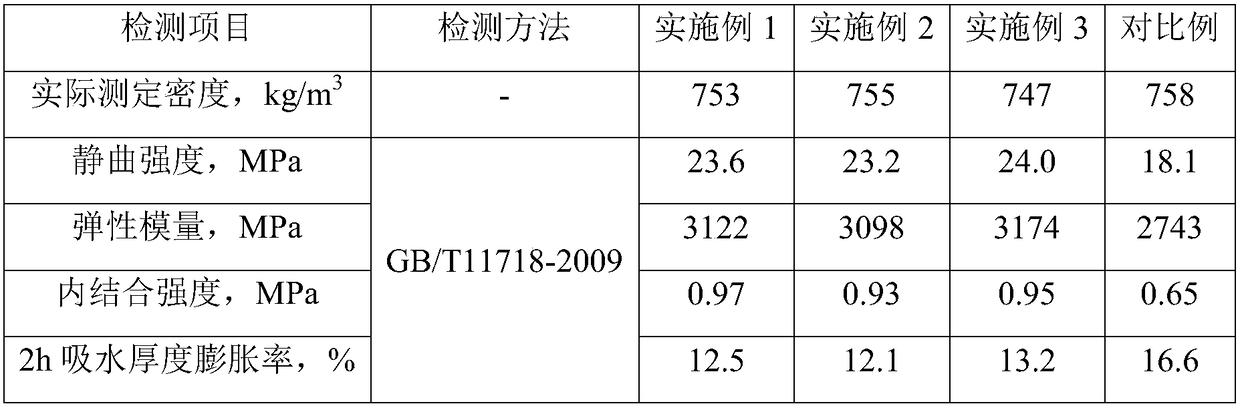

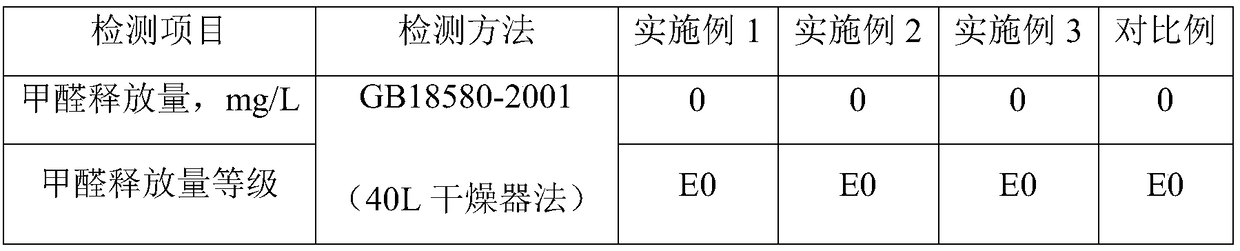

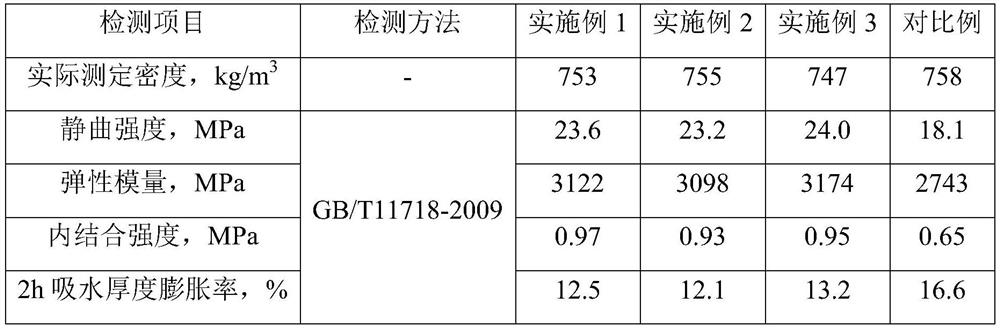

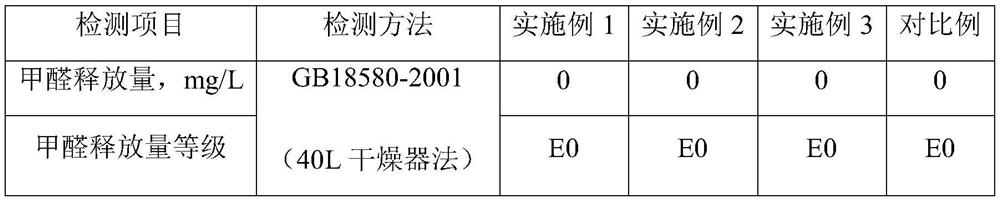

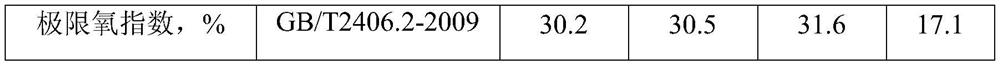

Environment-friendly flame-retardant non-adhesive fiberboard of crop straw and preparation method thereof

ActiveCN108656305AHigh bonding strengthImprove mechanical propertiesWood working apparatusDomestic articlesFiberFiberboard

The invention relates to an environment-friendly flame-retardant non-adhesive fiberboard of crop straw and a preparation method thereof. The fiberboard is prepared by the following steps that 1 ) wheat straw and sorghum straw are taken to be cut off correspondingly, and the wheat straw and the sorghum straw are soaked in water to obtain a softened material; 2 ) steam explosion is correspondingly carried out on the softened material to obtain wheat straw fiber and sorghum straw fiber; 3 ) nano calcium carbonate, nano zinc oxide are mixed with nano copper oxide, and modifying is carried out toobtain a modified additive A; nano zinc borate, the nano zinc oxide are mixed with the nano copper oxide, and modifying is carried out to obtain a modified additive B; 4 ) the wheat straw fiber and the sorghum straw fiber are mixed with the modified additive A to obtain a core layer mixture; the wheat straw fiber is mixed with the modified additive B to obtain a surface layer mixture; and 5 ) thecore layer mixture is taken as a core layer, the surface layer mixture is taken as a surface layer to be laid and pre-pressed to obtain a slab, after hot-pressing forming and post-treatment are carried out, the environment-friendly flame-retardant non-adhesive fiberboard is obtained. The fiberboard has no formaldehyde release and has good mechanical property, good anti-water, moisture-proof, anti-corrosion and antibacterial properties; and good in fireproof and flame-retardant effects, and suitable for popularization and application.

Owner:霸州市光洋人造板制造有限公司

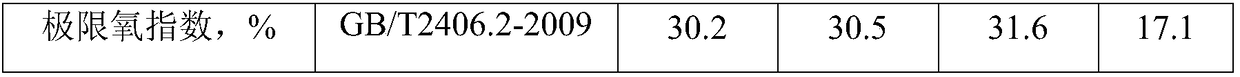

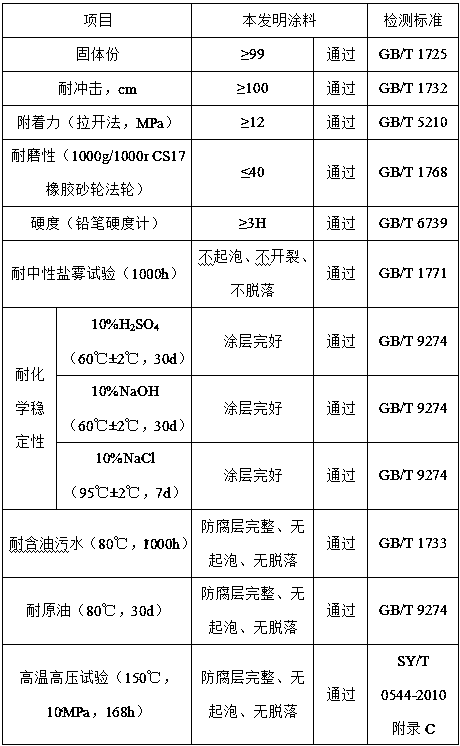

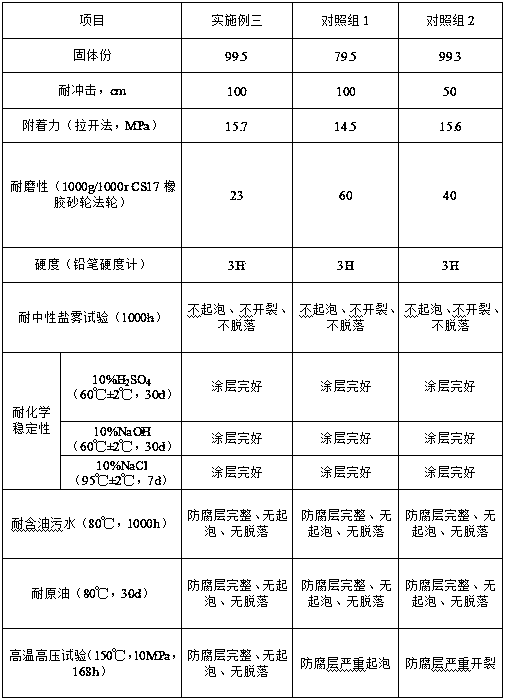

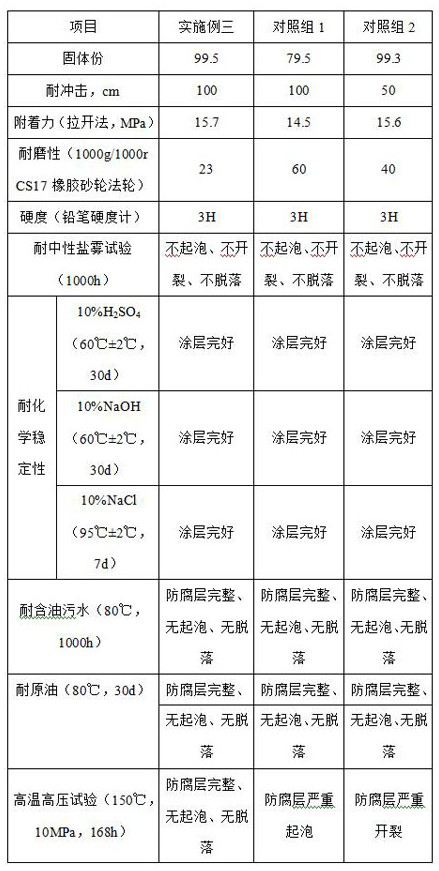

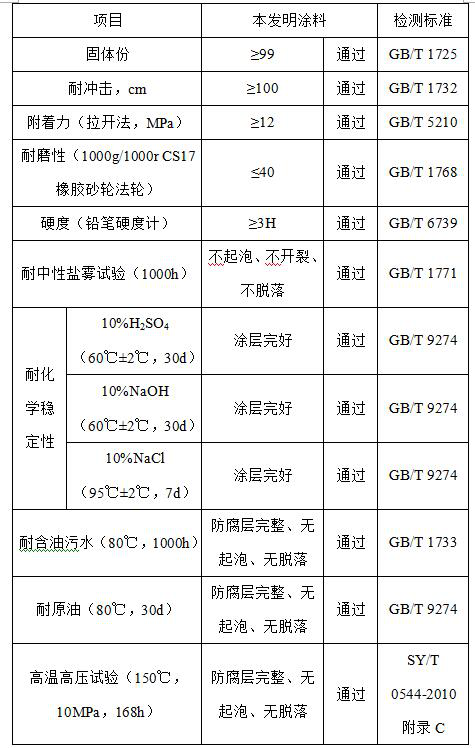

High-temperature and high-pressure resistant solvent-free heavy anti-corrosion paint and preparation method thereof

ActiveCN111334166AGood flexibilityImprove erosion resistanceFireproof paintsAnti-corrosive paintsSolvent freeFatty amine

The invention relates to a high-temperature and high-pressure resistant solvent-free heavy anti-corrosion paint composition, which comprises a material A and a material B. The material A is prepared from the following components: 40-60 parts of phenolic epoxy resin, 5-10 parts of bisphenol F resin, 5-10 parts of a reactive toughening agent, 5-10 parts of an active diluent, 1-3 parts of a thixotropic agent, 5-10 parts of a heat-resistant pigment, 1-2 parts of an auxiliary agent and 5-10 parts of filler; and the material B is 20-30 parts of a curing agent and is a mixture of modified fatty amineand modified phenolic aldehyde amine. The high-temperature and high-pressure resistant solvent-free heavy anti-corrosion paint is a solvent-free system, is environmentally friendly and green, can benormally constructed at a temperature of 0-40DEG C, is cured at the normal temperature and does not need to be heated. And after the paint is completely cured, a long-acting anti-corrosion function can be achieved under the high-pressure high-temperature and heavy corrosion working conditions of a watering pipeline, a high-pressure gas collecting pipeline and the like, the use efficiency of a conveying pipeline is improved, and the conveying safety is improved.

Owner:西安天元合成材料有限公司

Spunlaced nonwoven

ActiveCN107904781ABalanced flushabilityBalance strengthNon-woven fabricsEngineeringUltimate tensile strength

The invention provides a spunlaced nonwoven. The spunlaced nonwoven includes a base layer, a water absorption layer and a functional layer which are arranged sequentially from top to bottom and in reinforced connection through spunlace; the base layer includes 61-71 parts by mass of first plant fiber and 29-39 parts by mass of fine denier synthetic fiber; the water absorption layer is a second plant fiber layer; the functional layer includes 65-75 parts by mass of third plant fiber and 25-35 parts by mass of fine denier synthetic fiber; the first plant fiber includes bamboo pulp and tea tree wood pulp; second plant fiber includes bamboo pulp and tea tree wood pulp; the third plant fiber includes bamboo pulp, tea tree wood pulp, fructus cnidii straw pulp and golden cypress pulp. The spunlaced nonwoven adopts a three-layer structure, and uses the plant fiber and the fine denier synthetic fiber, the dispersed ability and intensity of the spunlaced nonwoven are effectively balanced, and the unification of the dispersed ability and the intensity is achieved. According to different use characteristics, the three layers are set with different ratios, and the most beneficial use effect isachieved.

Owner:福建恒安家庭生活用品有限公司

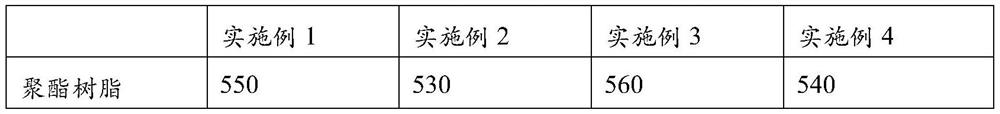

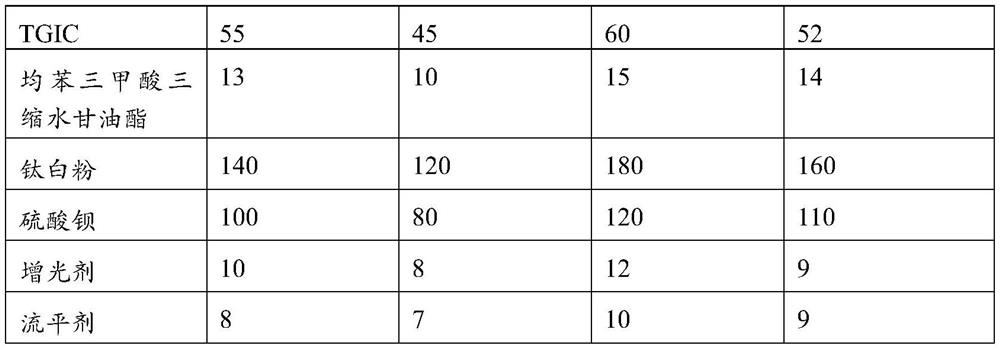

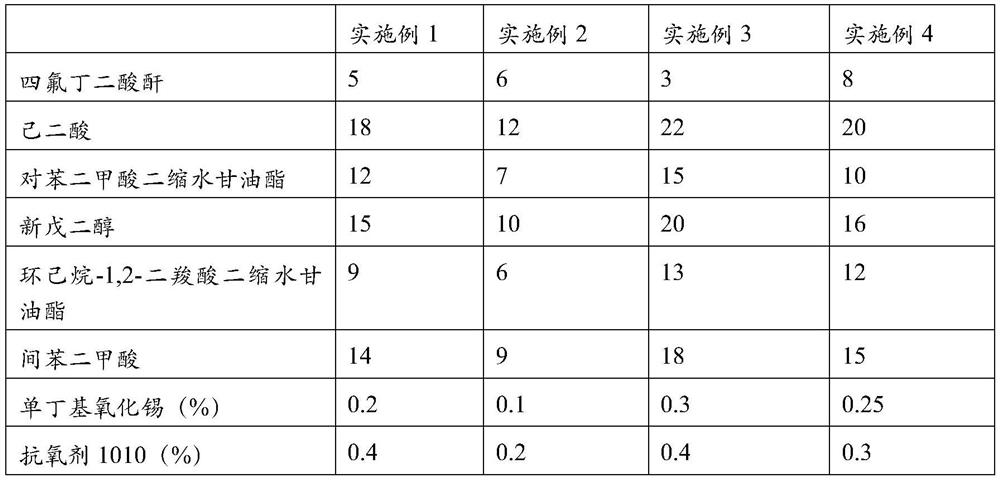

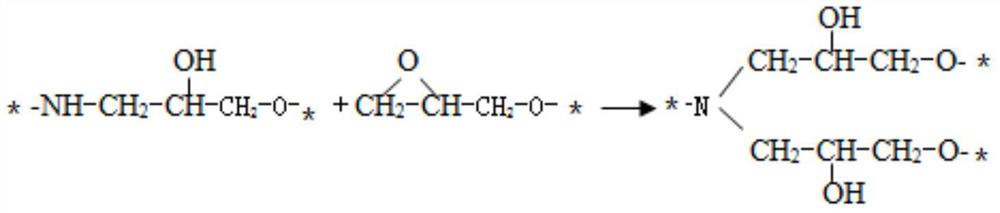

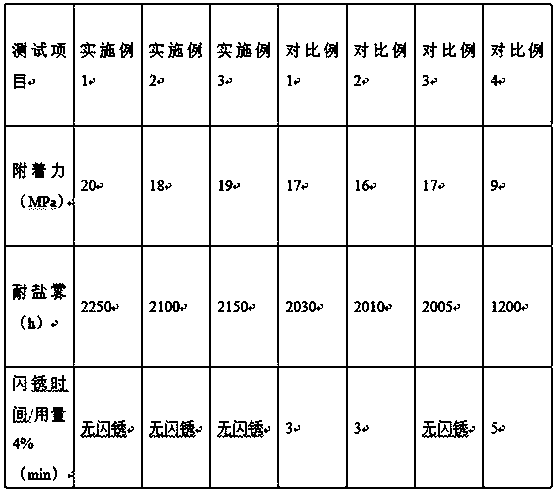

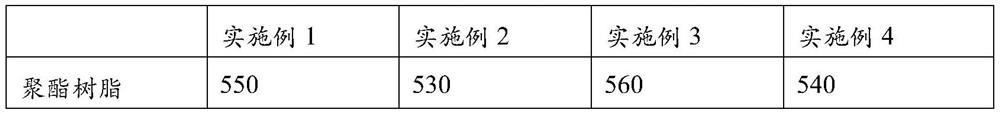

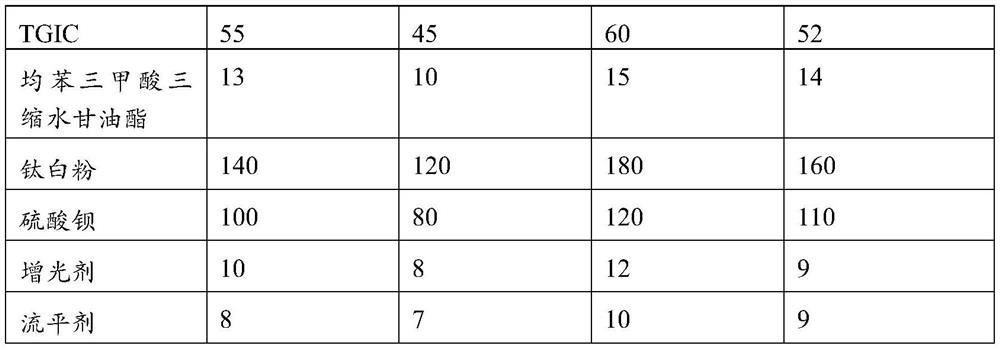

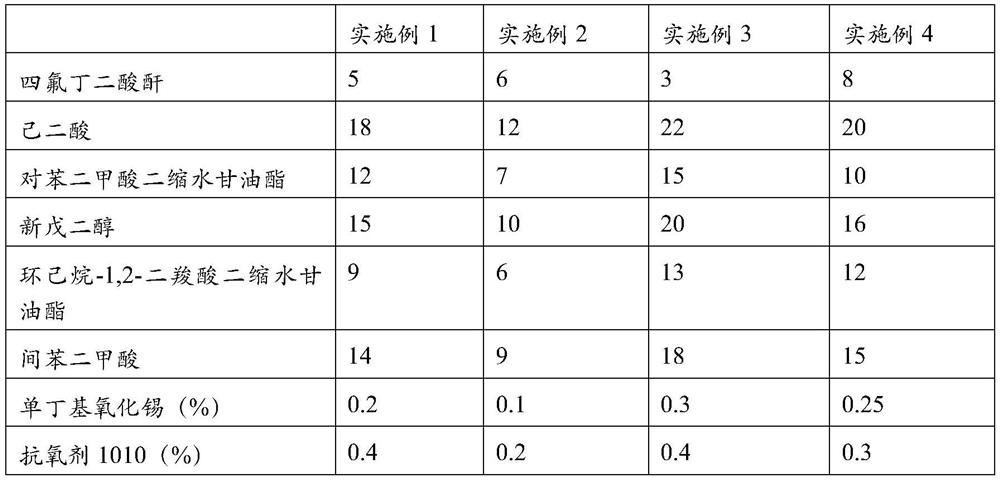

Long-acting weather-resistant chlorine salt corrosion-resistant polyester powder coating and preparation method thereof

ActiveCN112048235AGood linear structureLow softening pointAnti-corrosive paintsPowdery paintsWeather resistanceFirming agent

The invention belongs to the technical field of preparation of polyester powder coatings, and particularly relates to a long-acting weather-resistant chlorine salt corrosion-resistant polyester powdercoating and a preparation method thereof. The powder coating comprises the following main raw materials in parts by weight: 530-560 parts of polyester resin, 45-60 parts of TGIC, 10-15 parts of triglycidyl trimellitate, 120-180 parts of titanium dioxide, 80-120 parts of barium sulfate, 8-12 parts of a brightening agent and 7-10 parts of leveling agent. The polyester resin used in the powder coating is good in linear structure, and excellent flowing performance is guaranteed; more trifunctional curing agents TGIC are used in the powder coating and matched with triglycidyl trimellitate with a low melting point and excellent water resistance to jointly serve as a low-temperature curing agent, the crosslinking density and water resistance of a coating film are further improved, and finally long-acting weather resistance and chlorine salt corrosion resistance are guaranteed. The final powder coating product can be used for low-temperature curing at 160 DEG C, and the prepared coating filmhas excellent long-acting weather resistance and chlorine salt corrosion resistance, and is especially suitable for infrastructure spraying of expressways, such as guardrails and bridges.

Owner:安徽鑫友高分子新材料科技有限公司

Clean anti-freezing solution for automobiles and preparation method thereof

The invention discloses a clean anti-freezing solution for automobiles, and belongs to the technical field of anti-freezing solutions. The anti-freezing solution is obtained from reacting the following components in parts by weight: 80-90 parts of propylene glycol, 10-30 parts of deionized water, 2-3 parts of a decarbonizer, 10-20 parts of a corrosion inhibiter, 5-10 parts of silicate, 6-8 parts of a silicate stabilizer, 1-3 parts of a defoamer and 1-5 parts of a colorant, wherein the decarbonizer is prepared from the following raw materials by weight proportion: 90% of deionized water, 5% of triethanolamine, 1% of a surfactant and 4% of a foaming agent; the corrosion inhibiter adopts triethanolamine. The invention also discloses a preparation method of the anti-freezing solution. The clean anti-freezing solution for automobiles provided by the invention can provide long-acting corrosion protection through the homemade decarbonizer, is low in cost, environment-friendly and free of pollution, and avoids gel deposition and scale formation; the preparation method of the clean anti-freezing solution for automobiles is simple and environment-friendly in steps and easy to operate.

Owner:赵兰

High-temperature wear-resistant heavy-duty anticorrosion powder coating, and preparation method and coating method thereof

PendingCN113861805ALow costReduce well maintenance and repair costsLiquid surface applicatorsAnti-corrosive paintsFirming agentPowder coating

The invention provides a high-temperature wear-resistant heavy-duty anticorrosion powder coating, and a preparation method and a coating method thereof. The high-temperature wear-resistant heavy-duty powder coating comprises, by mass, 50-65 parts of phenolic modified epoxy resin, 3-9 parts of a curing agent, 3-5 parts of an organic wear-resistant filler, 5-10 parts of an inorganic wear-resistant filler, 3-7 parts of a solid wear-resistant lubricant, 15-30 parts of a pigment filler, 0.2-0.5 part of a curing accelerator and 0.8-1.5 parts of a leveling agent. The components of the high-temperature wear-resistant powder coating are all commercially available materials, are simple and easy to obtain, and are low in cost; and the phenolic aldehyde modified epoxy resin with high strength, heat resistance and acid and alkali resistance is adopted as a main film-forming matter, the long-acting corrosion resistance can still be kept in the harsh H2S / CO2 corrosion environment, and a high-temperature wear-resistant anticorrosion coating layer can be obtained through the high-temperature wear-resistant heavy-duty anticorrosion powder coating.

Owner:北京天乙长科技发展有限公司

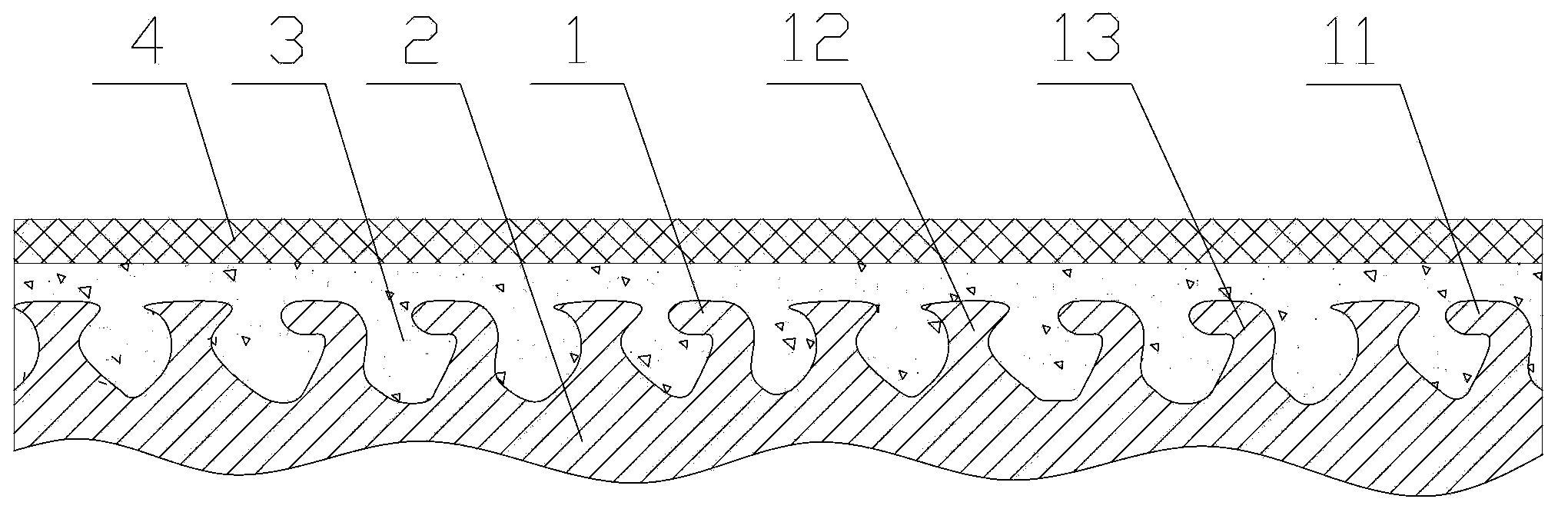

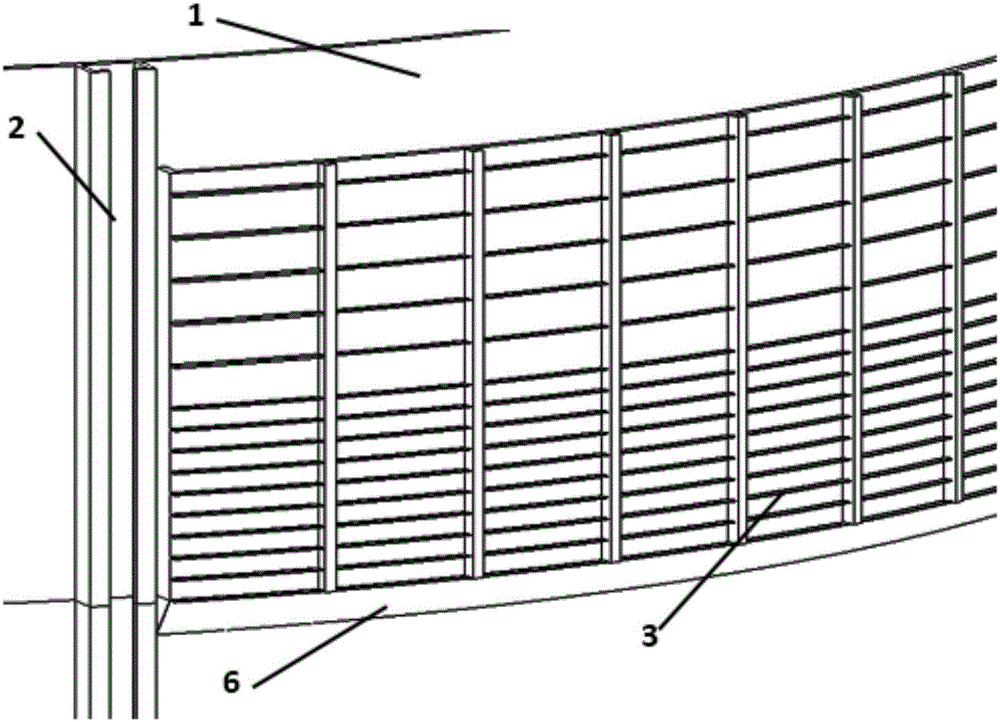

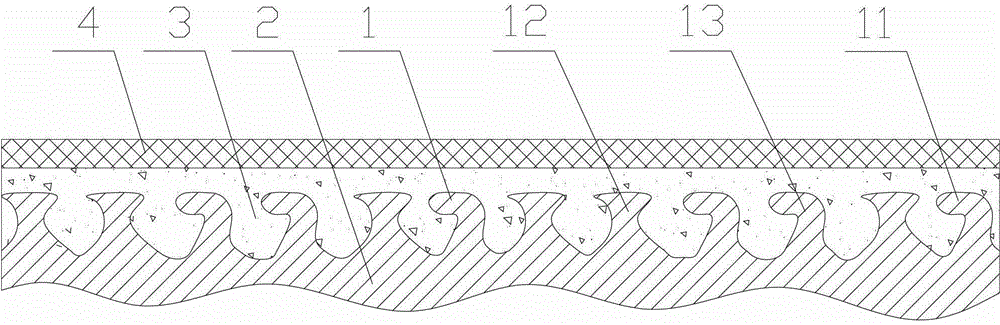

Anchor hook type composite anticorrosive metal member and making technology thereof

ActiveCN103434197AImprove adhesionGood value for moneyLamination ancillary operationsLaminationElectrical polarityZinc

The invention relates to metal surface anticorrosion, and discloses an anchor hook type composite anticorrosive metal member and a making technology thereof. The anticorrosive metal member comprises a metal substrate (2), a metal substrate anchor hook layer (1), an occlusion layer (3) and an anticorrosive layer (4), the metal substrate anchor hook layer (1) comprises flat-headed anchor hooks (11), the metal substrate anchor hook layer (1) has an embedded anchoring connection with the occlusion layer (3), and the anticorrosive layer (4) is arranged outside the occlusion layer (3). The making technology comprises the following steps: 1, making anchor grains having a roughness of 150-1500mum on the surface of the metal substrate; 2, pressing the anchor grains of the metal substrate to form the metal substrate anchor hook layer; and 3, coating to form the occlusion layer. In the invention, the high-roughness anchor hook type anchor grains are made on the base surface, an organic material of polar molecules or a Zn-Al anticorrosive metal binding layer is adopted to make the anchor hook type composite layer, and the composite layer has the characteristics of high adhesion, low energy consumption, high cost performance and long-acting anticorrosion.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Special oil for protecting screw of T type railway rail

InactiveCN1693434AStrong adhesionGood viscosity temperature performanceRail fastenersBase-materialsLithium soapLanolin

A protective grease for the T-shaped screw bolt of railway is proportionally prepared from fatty acid lithium soap, lanolin magnesium soap, barium dinonyl naphthalenesulfonate, enylbutanedioic acid, silican oil, phenyl-alpha-naphthaleneamine, and synthetic alkylbenzene oil. Its advantages are high anticorrosion, antirust, antiageing and water-proof effect and high adhesion.

Owner:安阳市天佑铁路材料科技有限责任公司

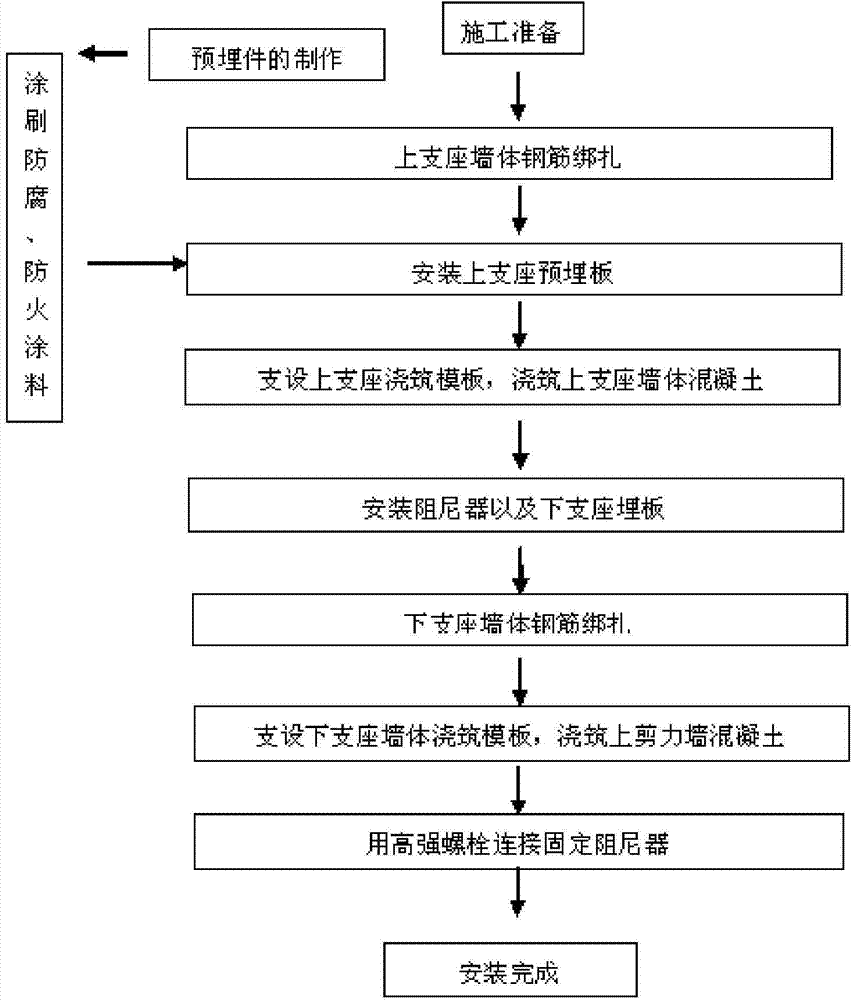

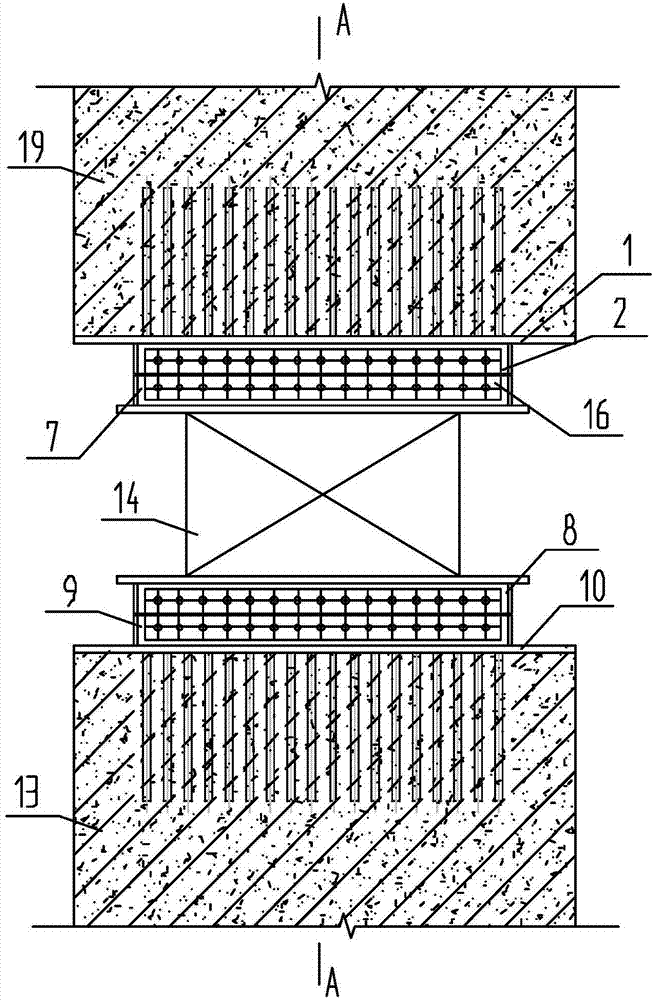

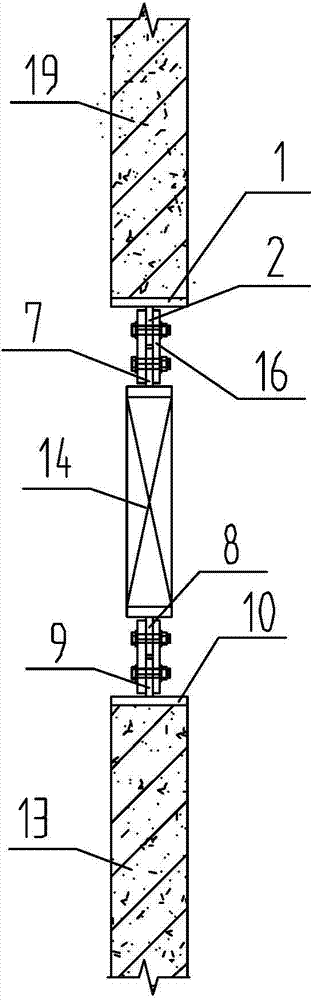

Top-down mounting and constructing method of soft-steel energy-dissipation damper system

InactiveCN104847034AAdvantages of installation and construction methodsPrevent leakageBuilding material handlingShock proofingRebarShock absorber

The invention provides a top-down mounting and constructing method of a soft-steel energy-dissipation damper system. The top-down mounting and constructing method includes binding upper bracket wall ribs and mounting an upper bracket embedded plate in advance; erecting and reinforcing an upper bracket wall casting template and casting upper bracket wall concrete; demounting the upper bracket wall casting template after an upper bracket wall is formed; mounting a damper and welding a lower bracket embedded plate on a lower damper connecting plate; binding lower bracket wall ribs, and erecting and reinforcing a lower bracket wall casting template; opening the upper portion of the lower bracket wall, mounting a discharge hopper and casting lower bracket wall concrete; demounting the lower bracket wall casting template after the lower bracket wall is formed. The damper system is mounted from top to bottom, the lower bracket wall can be adjusted slightly after casting of the upper bracket wall, and the problem of failure in damper mounting due to error caused by construction quality is avoided.

Owner:天津住宅集团建设工程总承包有限公司

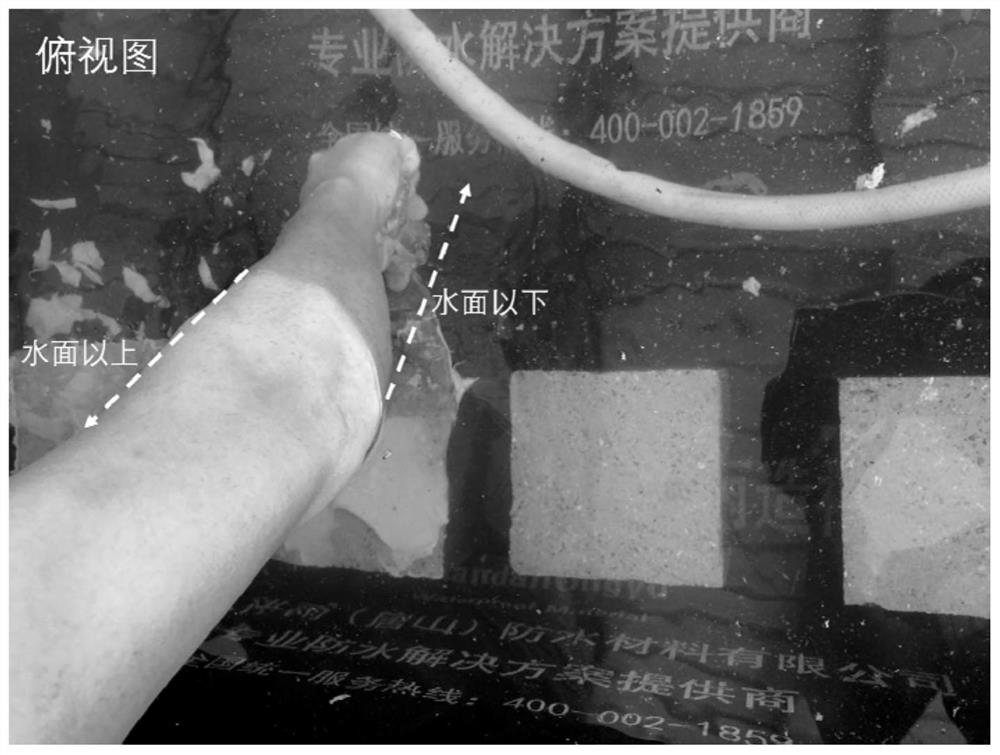

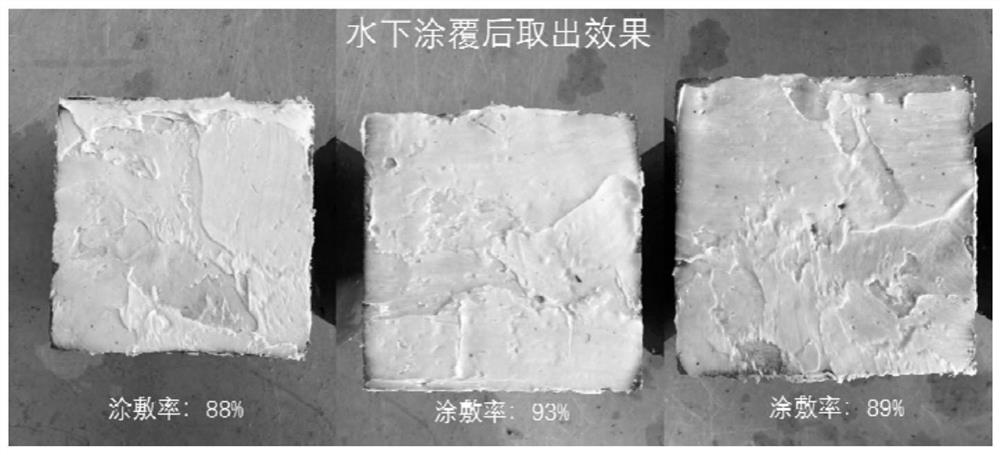

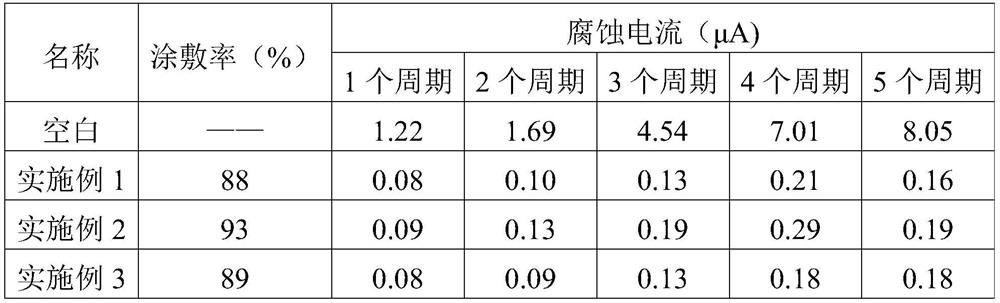

Anti-corrosion paste and preparation method thereof

ActiveCN112795311AEasy constructionHigh crack followingAnti-corrosive paintsRebarCorrosion prevention

The invention discloses an anti-corrosion paste. The anti-corrosion paste is prepared from the following components in percentage by weight: 35 to 80 percent of basic grease, 0.5 to 5 percent of high-permeability corrosion inhibitor, 0.5 to 20 percent of surfactant, 18 to 30 percent of thickening agent and 1 to 10 percent of plasticizer. The invention further discloses a preparation method of the anti-corrosion paste. The anti-corrosion paste is suitable for corrosion prevention of a concrete member in a water level change area, so that underwater construction is convenient, a water layer on the surface of concrete can be effectively replaced, pores on the surface of the concrete can be fully filled, the anti-corrosion paste has high crack followability, meanwhile, the permeable corrosion inhibitor can permeate into the concrete to effectively protect reinforcing steel bars, and the comprehensive anti-corrosion effect is excellent.

Owner:中路高科交通检测检验认证有限公司

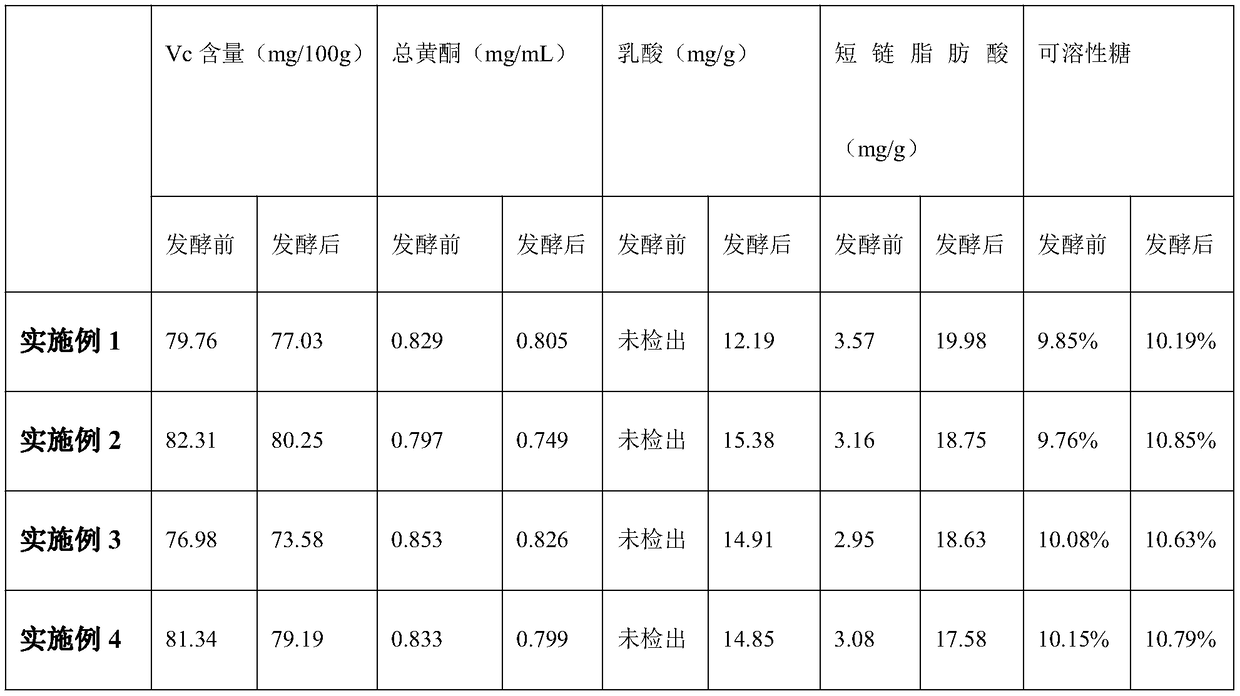

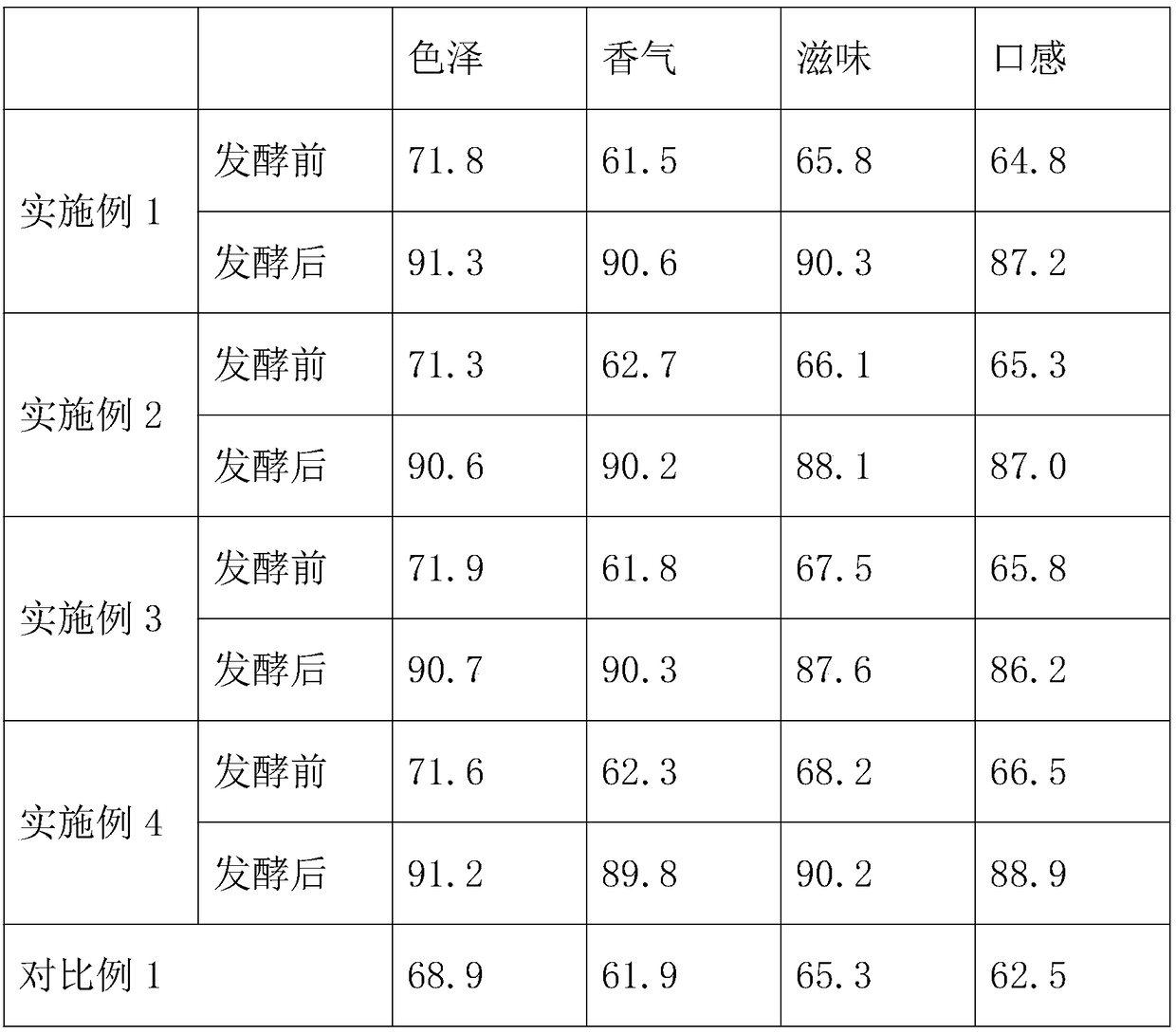

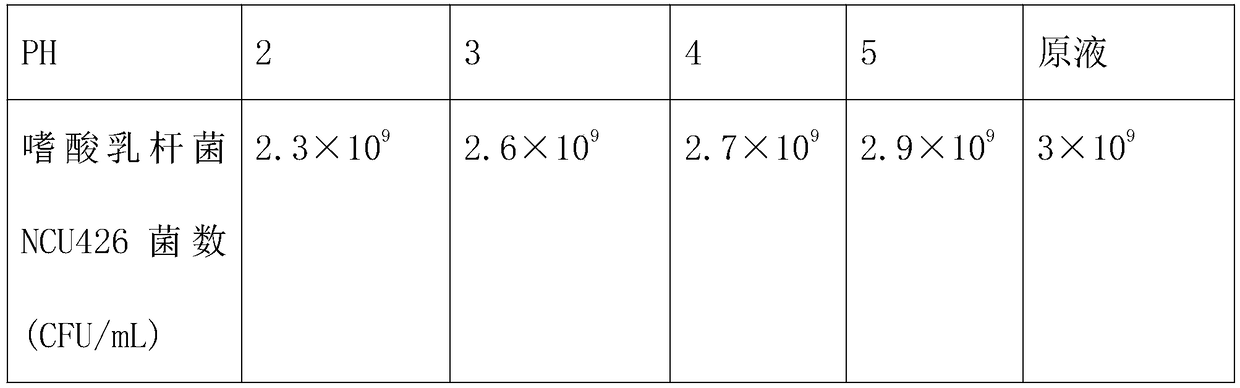

Fermented haw pulp and preparation method

ActiveCN109393390ANutritious and balancedMild sourFood ingredient functionsPolysaccharide/gum food ingredientsLactobacillus acidophilusMicrobiological culture

The invention provides fermented haw pulp and a preparation method. The fermented haw pulp is prepared through performing fermentation with a lactobacillus acidophilus NCU426 fermenting agent, lactobacillus acidophilus NCU426 is preserved in China General Microbiological Culture Collection Center on 9th April 2018, wherein the address of the China General Microbiological Culture Collection Centeris Institute of Microbiology, Chinese Academy of Sciences at No. 3, No. 1 yard, Beichen Western road, Chaoyang district, Beijing, the China General Microbiological Culture Collection Center is abbreviated as CGMCC, and the preservation serial number is CGMCC NO15572. Through adoption of the preparation method, original nutrient components of Vc, flavone and the like in the haws can be effectivelyreserved, and through fermentation, probiotic active metabolism products of short chain fatty acids, sticky polysaccharide, polypeptide and the like can be produced; and compared with an unfermentablehaw pulp product, the fermented haw pulp is richer and balanced in nutrients.

Owner:NANCHANG UNIV

Graphene heavy anti-corrosion coating and preparation method thereof

InactiveCN108997892AFull dispersionFully stretchAnti-corrosive paintsEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to an anti-corrosion coating, and particularly relates to a graphene heavy anti-corrosion coating and preparation method thereof. The coating comprises a component A and a component B, wherein the component A includes, by weight, 10-15 parts of epoxy resin, 2-5 parts of polyurethane modified epoxy resin, 10-20 parts of a solvent, 0.05-0.5 parts of modified graphene, 45-65 parts of an anti-rust pigment, 5-10 parts of mica powder, 1-2 parts of titanium dioxide, 0.3-0.6 parts of a wetting dispersant, 0.03-0.06 parts of a defoamer, and 1-3 parts of organic bentonite; the component B includes, by weight, 55-70 parts of polyamide resin, 20-40 parts of a solvent, and 4-8 parts of an accelerant. Compared with the prior art, the graphene heavy anti-corrosion coating is prepared on the basis that the modified graphene is pre-dispersed in the solvent to make slurry, so that the graphene is fully dispersed and expanded in the coating to form a layered staggered structure. Thecoating has great shielding effect and is good in anti-corrosion effect.

Owner:MARINE CHEM RES INST

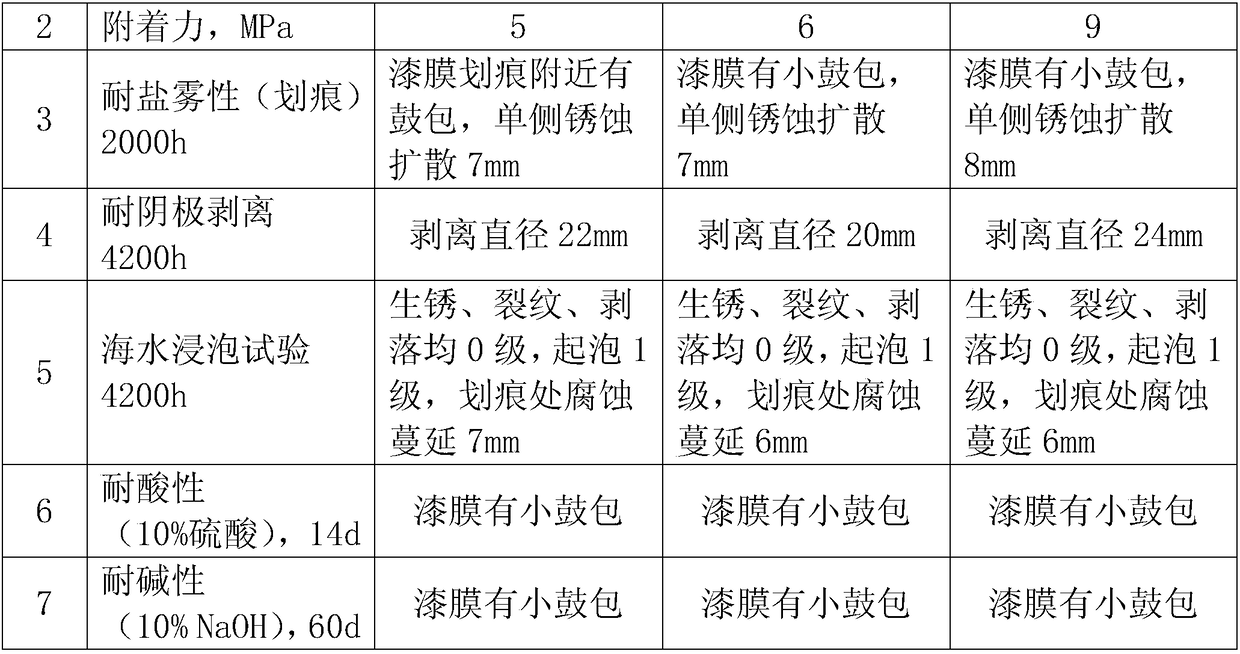

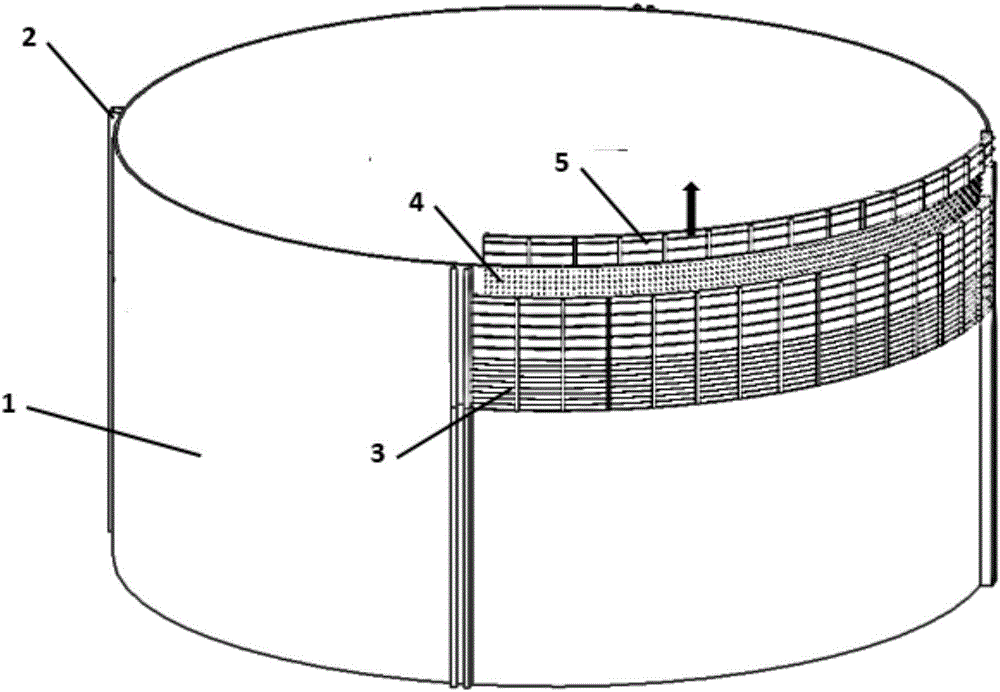

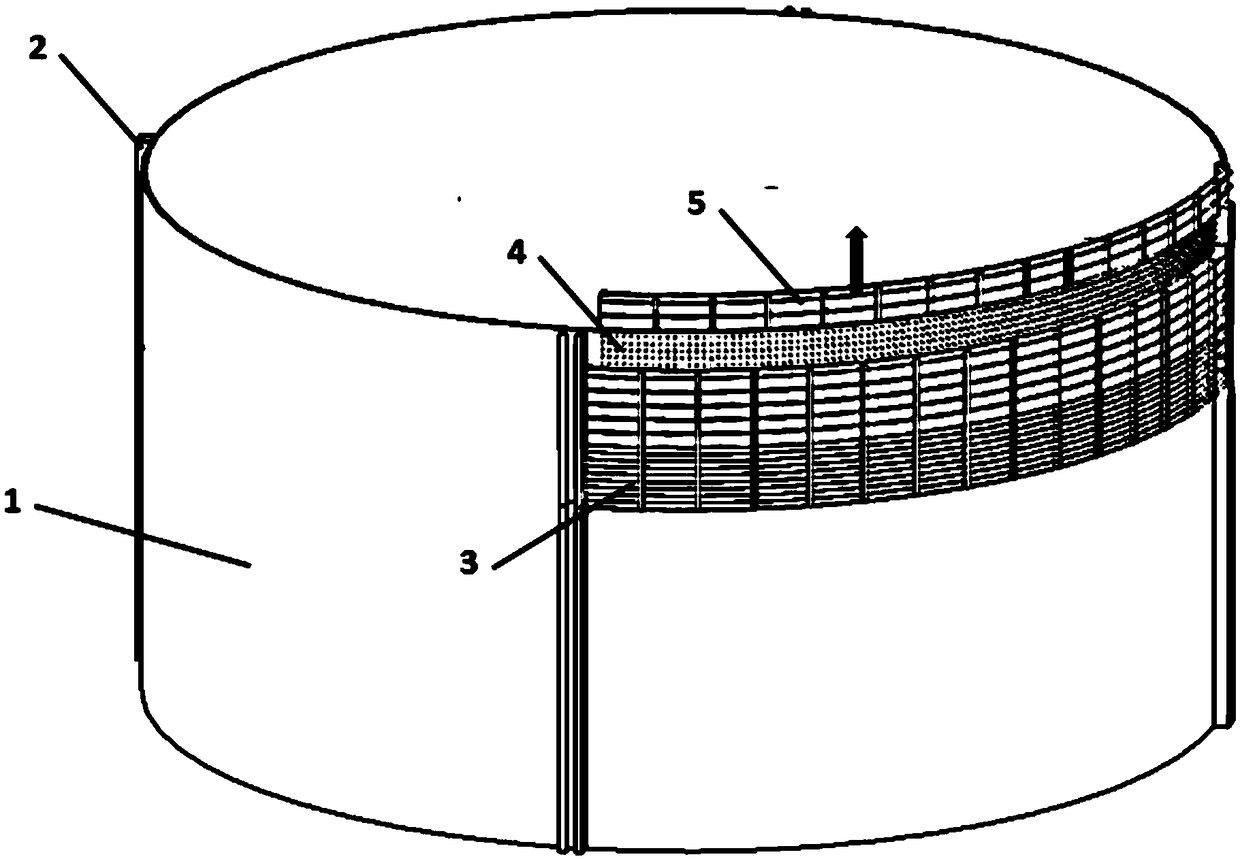

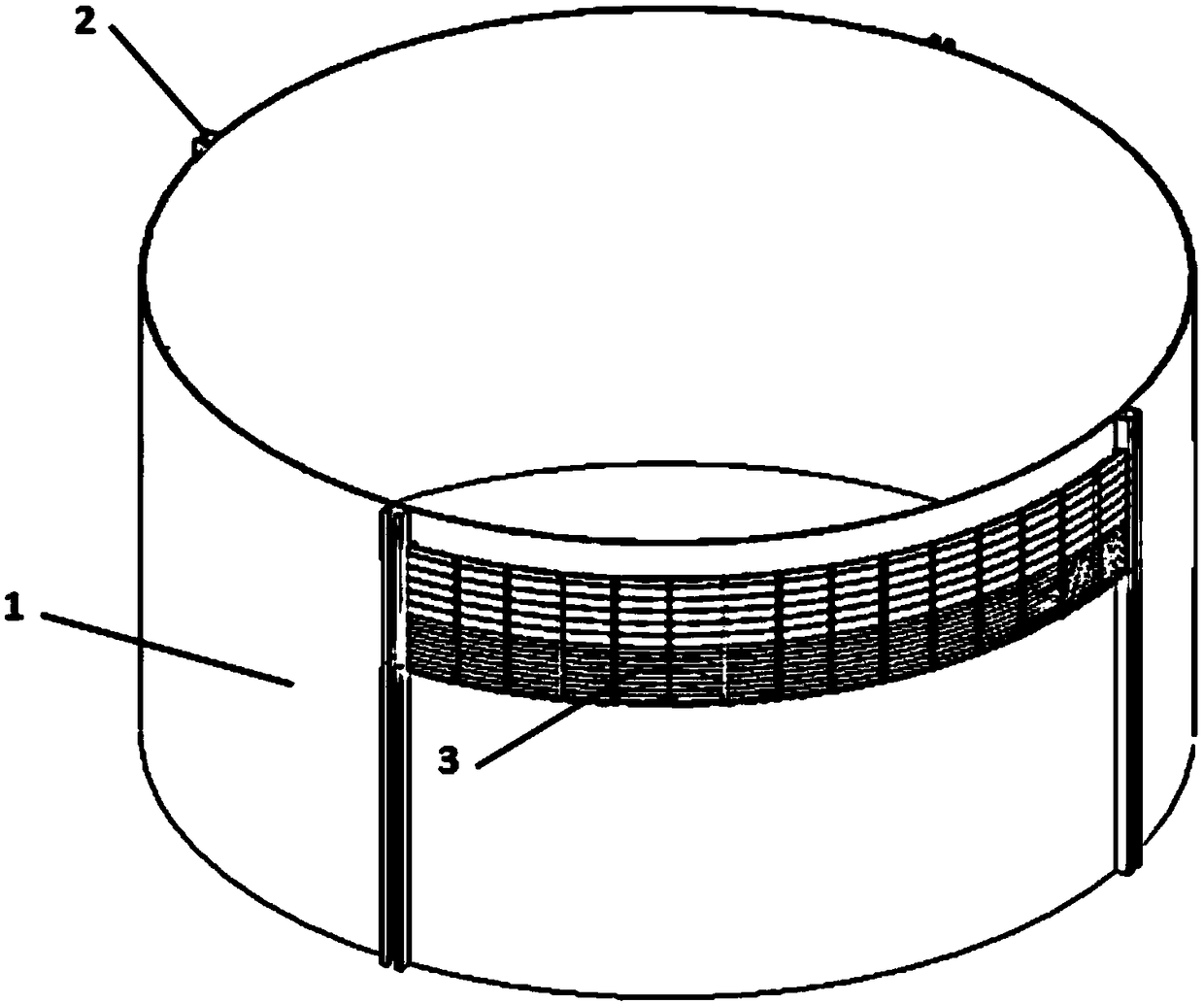

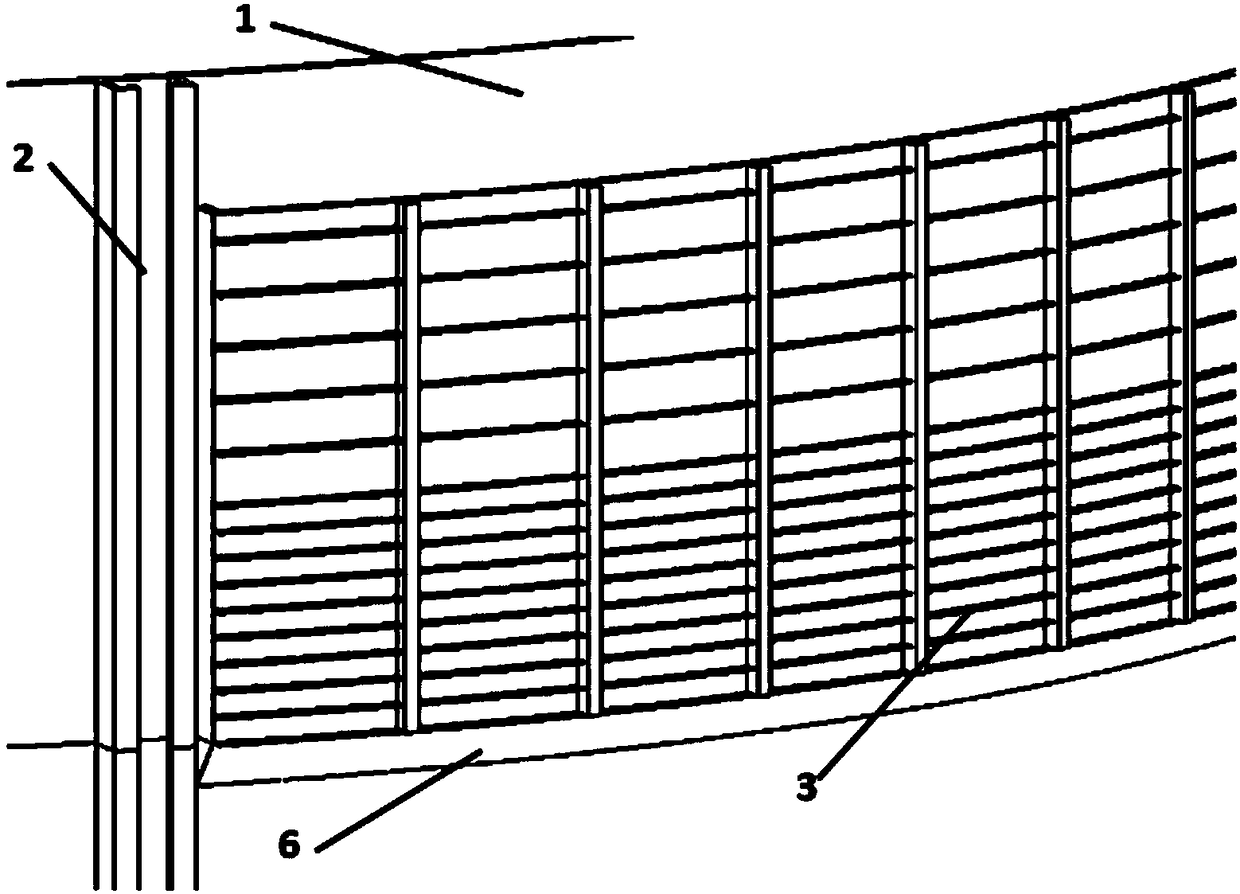

Concrete anticorrosive tooling construction method for splash zone of steel cylindrical bank protection structure

ActiveCN106759207ANo pollution in the processLong-term anti-corrosionArtificial islandsUnderwater structuresStructural engineeringTongue and groove

The invention discloses a concrete anticorrosive tooling construction method for a splash zone of a steel cylindrical bank protection structure. The concrete anticorrosive tooling construction method comprises the following steps of fixing shear resistant connecting structures along the outer wall of the periphery range of the splash zone of the steel cylindrical bank protection structure with mortise structures; welding die block supporting plates in the periphery range of the splash zone of the steel cylindrical bank protection structure at the bottom of the sear resistant connecting structure at certain distance intervals; mounting arc-shaped fixed die plates at the lower parts of the shear resistant connecting structures; welding arc-shaped bottom walls which are horizontally arranged at the bottoms of the fixed die plates; hoisting the steel cylindrical bank protection structure in water; mounting watertight sealing strips on the front walls of the fixed die plates, the tops of left side walls and the tops a right side walls of the fixed die plates; extracting water in a cavity between the fixed die plates, a movable die plate and the bank protection structure; and then casting coated concrete in the cavity. Through the adoption of the concrete anticorrosive tooling construction method disclosed by the invention, the condition that the marine steel cylindrical bank protection structure can realize long-acting corrosion prevention in the using period can be guaranteed.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

Anti-corrosion aqueous paint and preparation method thereof

InactiveCN109294364AReduce over-corrosionImprove protectionAnti-corrosive paintsPhosphateActive agent

The invention discloses an anti-corrosion aqueous paint and a preparation method thereof, which belong to a metal anti-corrosion paint. The method uses the itaconic acid as a raw material to obtain atransrust active agent, and the itaconic acid having a polyphenolic hydroxyl structure is used as a transrust reactant. The method takes phosphorus pentoxide and beta-hydroxyethyl acrylate having a bifunctional structure for a reaction to form corrosion-resistant phosphate and a passivation film, which has good adhesion, glossiness and unique anti-flashing function. The method adopts aniline and p-aniline as raw materials, so that the aqueous paint can prolong the anti-corrosion time of the coating film on the basis of anti-flashing of the formed film, so that the coating film can be long-lasting anticorrosive. In the present invention, methacrylic glyceride is added and an epoxy group is introduced, so that the density and water resistance of the coating film are improved. The method solves the problems that the current paint has poor flashing resistance and salt spray resistance, and a surface rust part cannot be transformed.

Owner:张芸

Long-acting weather-resistant, chlorine-salt corrosion-resistant polyester powder coating and preparation method thereof

ActiveCN112048235BGood linear structureLow softening pointAnti-corrosive paintsPowdery paintsWeather resistanceLow temperature curing

The invention belongs to the technical field of polyester powder coating preparation, and in particular relates to a long-acting weather-resistant, chlorine-salt corrosion-resistant polyester powder coating and a preparation method. The main raw materials of the powder coating of the present invention are: 530-560 parts of polyester resin, 45-60 parts of TGIC, 10-15 parts of trimesic acid triglycidyl ester, 120-180 parts of titanium dioxide, and 80-120 parts of barium sulfate , 8‑12 parts of brightening agent, 7‑10 parts of leveling agent. The polyester resin used in the powder coating of the present invention has a good linear structure, which ensures excellent fluidity; the powder coating uses a larger amount of trifunctional curing agent TGIC, and is matched with triglycidyl trimesic acid with a low melting point and excellent water resistance Esters are used as low-temperature curing agents to further improve the crosslinking density and water resistance of the coating film, and finally ensure long-term weather resistance and chloride salt corrosion resistance. The final powder coating product can be used for low-temperature curing at 160°C. The coating film prepared by it has good long-term weather resistance and chlorine salt corrosion resistance, and is especially suitable for infrastructure spraying on highways such as guardrails and bridges.

Owner:安徽鑫友高分子新材料科技有限公司

A high temperature and high pressure resistant solvent-free heavy-duty anti-corrosion coating and its preparation method

ActiveCN111334166BGood flexibilityImprove erosion resistanceFireproof paintsAnti-corrosive paintsSolvent freeFatty amine

Owner:西安天元合成材料有限公司

A kind of high solid low surface treatment epoxy zinc-rich primer and its preparation method and application

ActiveCN110144160BIncrease crosslink densityImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemical industryPolymer science

The invention relates to a high-solid surface-tolerant epoxy zinc-rich primer. The primer is prepared from a component A and a component B according to a weight ratio of (16-20):1; the component A comprises the following components in parts by weight: 5-9 parts of liquid phenolic epoxy resin, 6-15 parts of E20 solid epoxy resin, 0.5-1.5 parts of an active diluent, 0.1-0.3 part of a dispersing agent, 70-80 parts of main rust-proof pigment, 2-6 parts of chemical anti-rust pigment, 1.5-2.5 parts of an anti-settling agent and 3-4 parts of an organic mixed solvent; and the component B comprises thefollowing components in parts by weight: 1.5-2.5 parts of a polyamide curing agent, 2-3 parts of a Mannich base curing agent, 0.3-0.6 part of a silane coupling agent and 0.2-0.6 part of an organic mixed solvent. The invention also relates to a preparation method of the primer and a coating film. The primer is high in solid content and low in VOC content, is resistant to corrosion, has a long effect, has good adhesive force and salt fog resistance, and is particularly suitable for repairing and maintaining equipment in industries such as chemical industry, thermoelectricity, machinery and thelike.

Owner:江阴市大阪涂料有限公司

Special oil for protecting screw of T type railway rail

InactiveCN1295308CStrong adhesionGood viscosity temperature performanceRail fastenersBase-materialsLithium soapLanolin

A protective grease for the T-shaped screw bolt of railway is proportionally prepared from fatty acid lithium soap, lanolin magnesium soap, barium dinonyl naphthalenesulfonate, enylbutanedioic acid, silican oil, phenyl-alpha-naphthaleneamine, and synthetic alkylbenzene oil. Its advantages are high anticorrosion, antirust, antiageing and water-proof effect and high adhesion.

Owner:安阳市天佑铁路材料科技有限责任公司

An environmentally friendly flame-retardant adhesive-free particle board for crop straw and preparation method thereof

ActiveCN108582394BImprove mechanical propertiesHigh static bending strengthWood working apparatusFlat articlesCopper oxideAnti bacteria

Owner:NANJING HEADWAY FURNITURE CO LTD

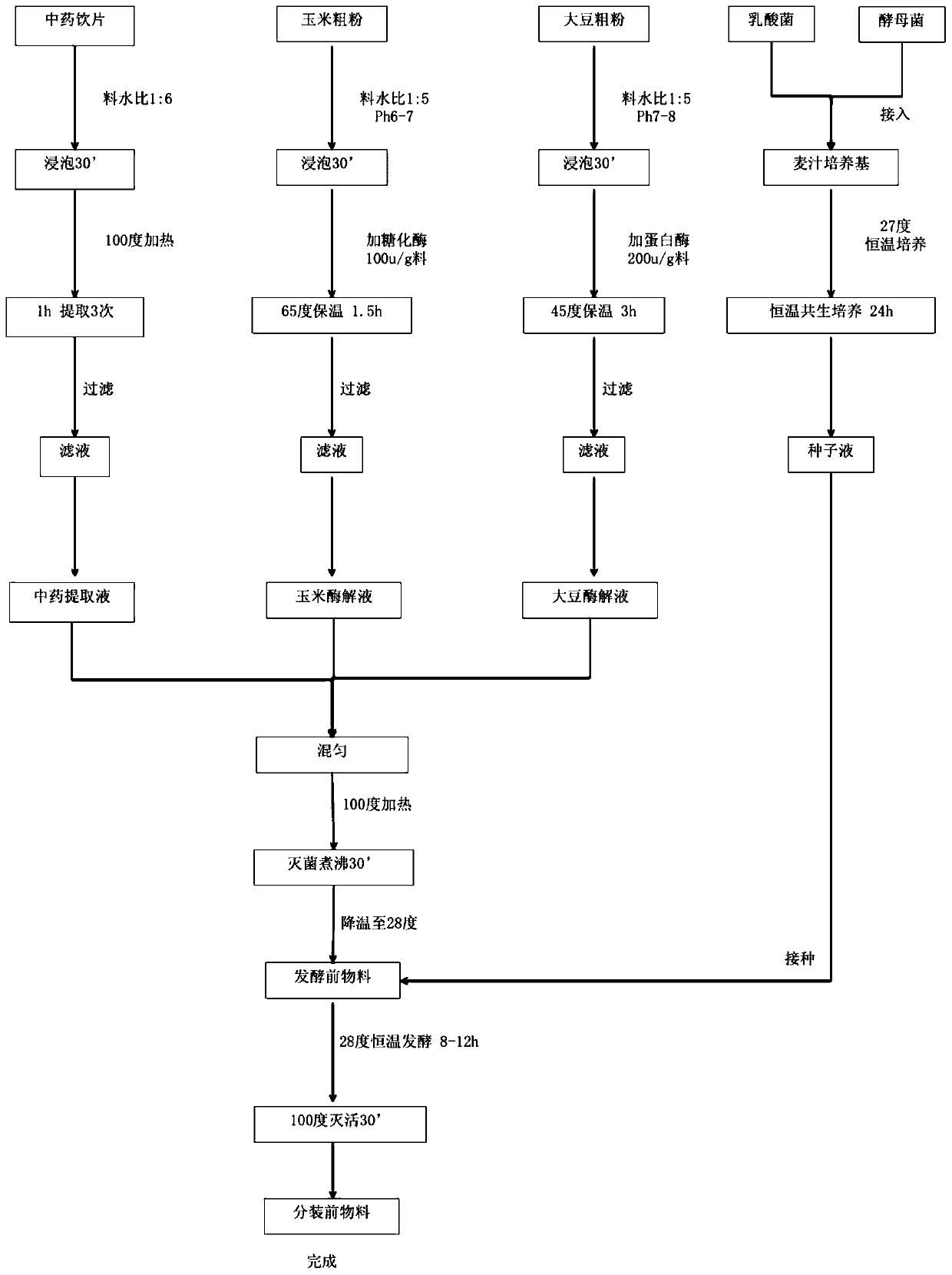

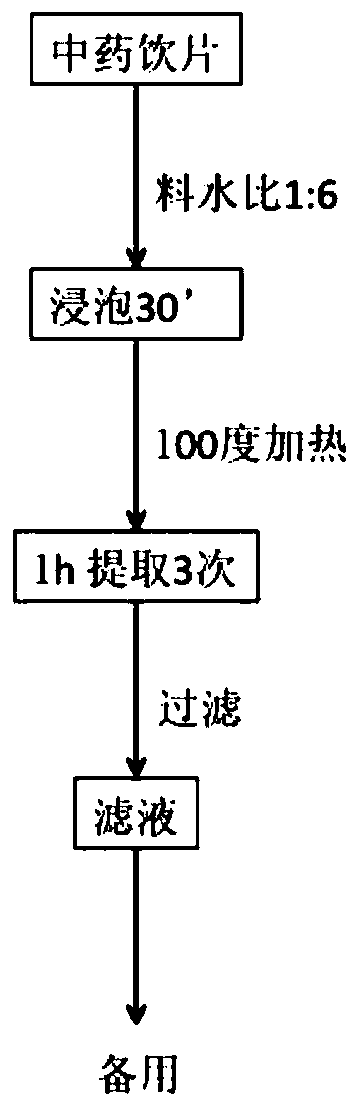

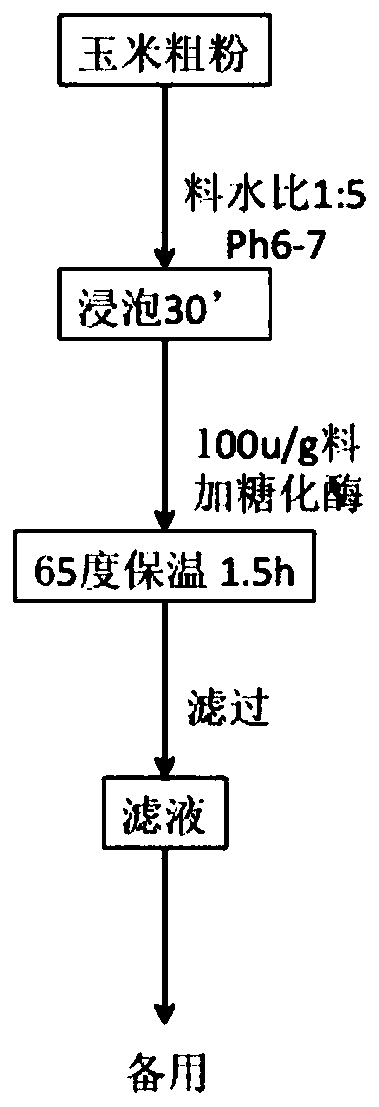

Preparation method of traditional Chinese medicine

The invention provides a preparation method of traditional Chinese medicine. The preparation method comprises the following steps that 1, a traditional Chinese medicine extracting solution is prepared; 2, a corn enzymolysis liquid is prepared; 3, a soybean enzymolysis liquid is prepared; 4, a probiotics seed solution is prepared; 5, a material before fermentation is obtained, wherein the traditional Chinese medicine extracting solution, the corn enzymolysis liquid and the soybean enzymolysis liquid are uniformly mixed, sterilized and boiled for 30 min at 100 DEG C and then cooled to 28 DEG C to prepare the material before fermentation; 6, the probiotics seed solution is added into the material before fermentation for inoculation and fermentation for 8-12 h to prepare a fermentation liquor;7, the fermentation liquor is inactivated for 30 min at 100 DEG C, and the preparation of the traditional Chinese medicine is completed. The preparation method of the traditional Chinese medicine hasthe advantages that the preparation of the traditional Chinese medicine is rapidly completed under the catalysis of enzymes and in the conditions of the normal temperature / normal pressure and appropriate ph value so that functional substances and nutrition ingredients in plant tissues can be fully and freely released, the raw materials of the traditional Chinese medicine are saved, the nutritionis rich, the taste is good, the absorptivity of the functional substances of the traditional Chinese medicine is high, and the long-term corrosion prevention can be achieved.

Owner:新圣宝健康科技(长春)有限公司

A kind of spunlace nonwoven fabric

Owner:福建恒安家庭生活用品有限公司

Phosphating process for phosphating layer on neodymium-iron-boron surface

The invention discloses a phosphating process for a phosphating layer on a neodymium-iron-boron surface. The process comprises the following steps of 1) preparing a phosphating solution: firstly adding a magnesium salt and a zinc salt into the solution, then dropwise adding phosphoric acid, after the phosphating solution is clarified, sequentially adding a buffering agent, a complexing agent, a surfactant and a phosphating accelerator, and finally adjusting a pH value of the phosphating solution by the phosphoric acid and sodium hydroxide; and 2) putting the phosphating solution into an electrolytic cell, and treating the phosphating solution on the surface of a neodymium-iron-boron matrix in an electrolytic phosphating mode. According to the process, the phosphating solution is treated onthe surface of the neodymium-iron-boron matrix in the electrolytic phosphating mode, so that the magnetic performance reduction due to the corrosion of the matrix can be avoided; and meanwhile, due to the adoption of the electrolytic phosphating method, the phosphating accelerator such as nitrite or the like does not need to be added into the phosphating solution, so that the environment is not polluted and disrupted.

Owner:FOSHAN UNIVERSITY

Environment-friendly motor vehicle antifreezing solution

The invention provides an environment-friendly motor vehicle antifreezing solution. The environment-friendly motor vehicle antifreezing solution is prepared from the following raw materials in parts by mass: 60-70 parts of alcohols, 0.1-0.3 part of silicate, 0.1-0.2 part of calcium chloride, 0.1-0.3 part of potassium nitrate, 1-2 parts of benzotriazole, 0.1-0.2 part of urea, 0.1-0.3 part of borax,10-100 parts of water, 3-10 parts of sodium stannate, 5-18 parts of benzotriazole, 1-7 parts of polysorbate, 3-7 parts of isothiazolinone, 1-6 parts of lanolin, 1-5 parts of a defoamer, 1-5 parts ofa water-based wetting agent and 2-8 parts of a corrosion inhibitor. The environment-friendly motor vehicle antifreezing solution has great anti-freezing performance, and is stable in chemical property, capable of achieving long-term anti-corrosion, environmentally friendly, free of pollution and suitable for parts such as engines of motor vehicles such as automobiles and tractors or motor equipment.

Owner:江苏中丽新材料有限公司

Graphene preservative and corrosion control method for mounting bracket

InactiveCN109096876ACompositionally stable and low viscosityStable low viscosityPretreated surfacesSolid state diffusion coatingSelf-healingChemical reaction

The invention provides a graphene preservative and a corrosion control method for a mounting bracket. The graphene preservative can permeate into a honeycomb structure and form a dense protective filmon the surface of the honeycomb structure, and has good acid resistance, salt resistance and corrosion resistance. According to the corrosion control method for the passenger dedicated signal devicemounting bracket, first a zincizing corrosion resistance technology is adopted to form a honeycomb zinc-iron alloy layer on the surface of a workpiece, and the graphene preservative is sprayed in a pressure environment of 0.4-0.6 MPa. The graphene preservative undergoes multiple physical and chemical reactions, and a labyrinth effect is formed on the honeycomb zinc-iron alloy layer by overlappingdistribution, and the graphene preservative fills tissue gaps. A graphene coating is evenly distributed, the extremely low gas or liquid permeability of the coating can be maintained, and a corrosivemedium diffusion way is effectively blocked. At the same time, an anode material is added in the graphene, so that the coating has a self-healing function, and even if the graphene coating is partially damaged, the corrosion can also be effectively suppressed, thereby achieving long-term corrosion protection.

Owner:饶阳铁建电务器材有限公司

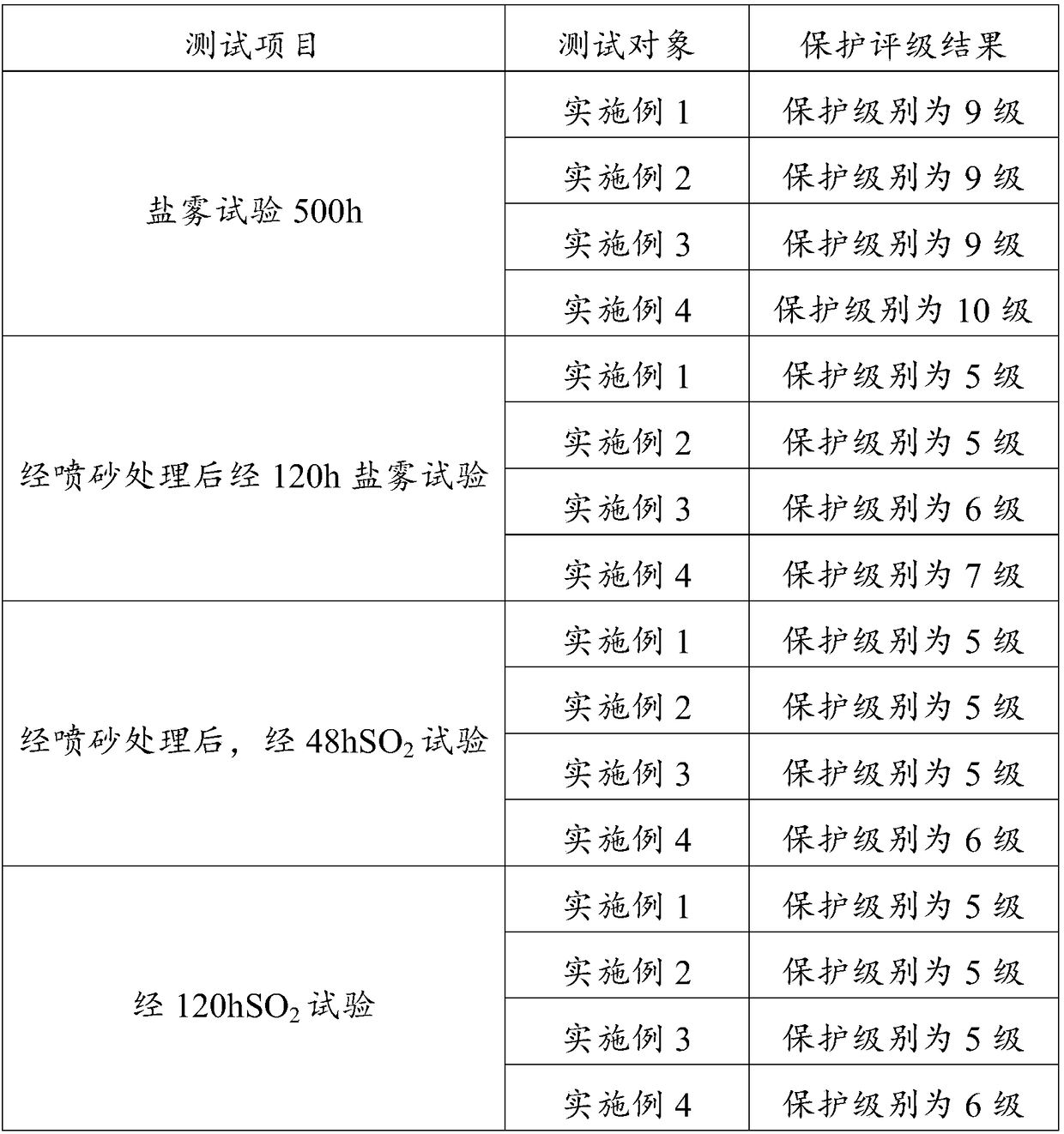

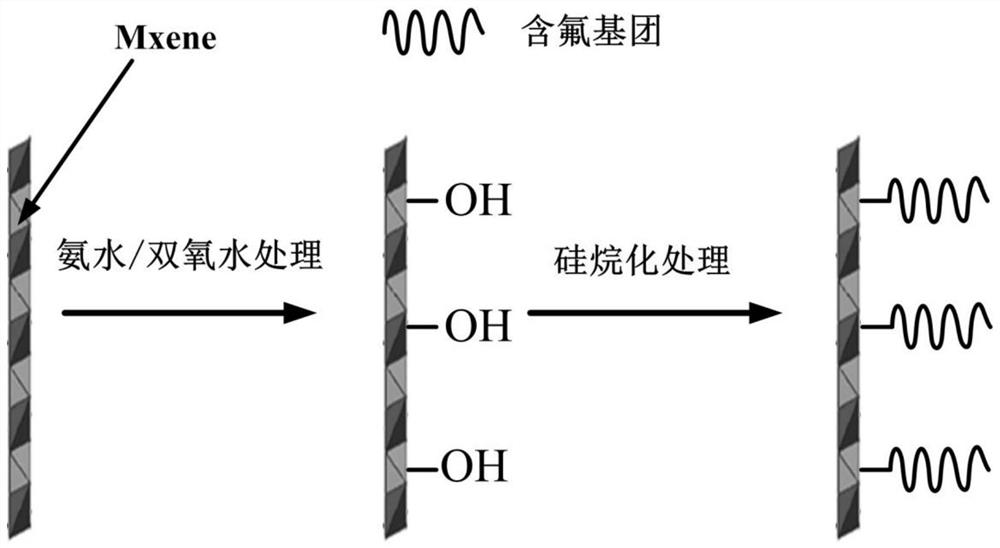

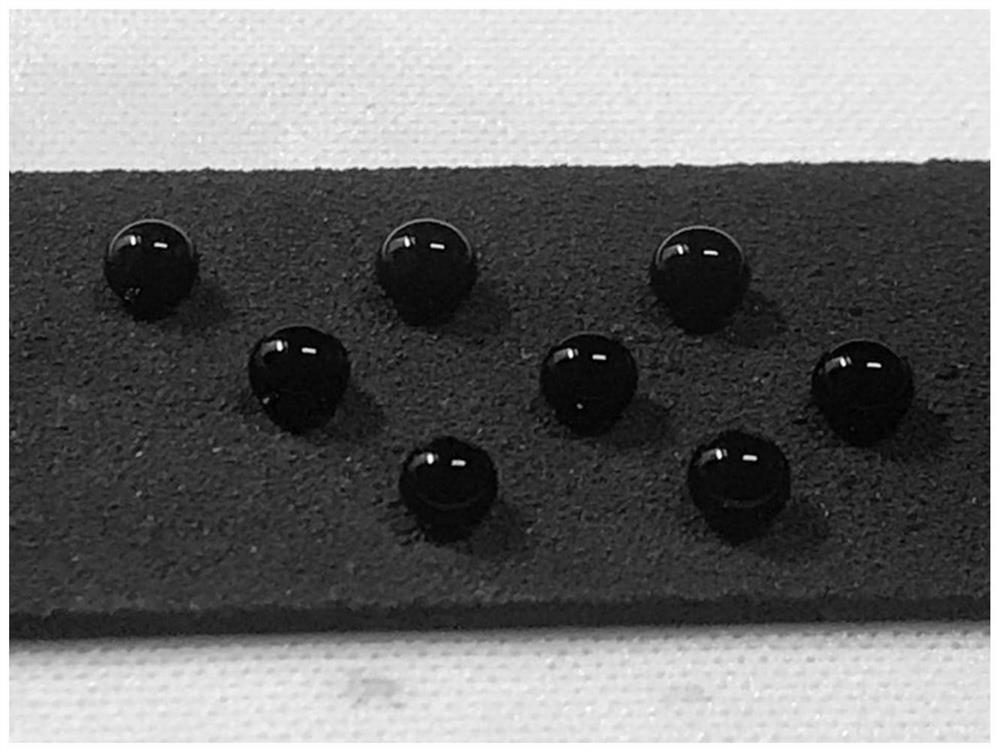

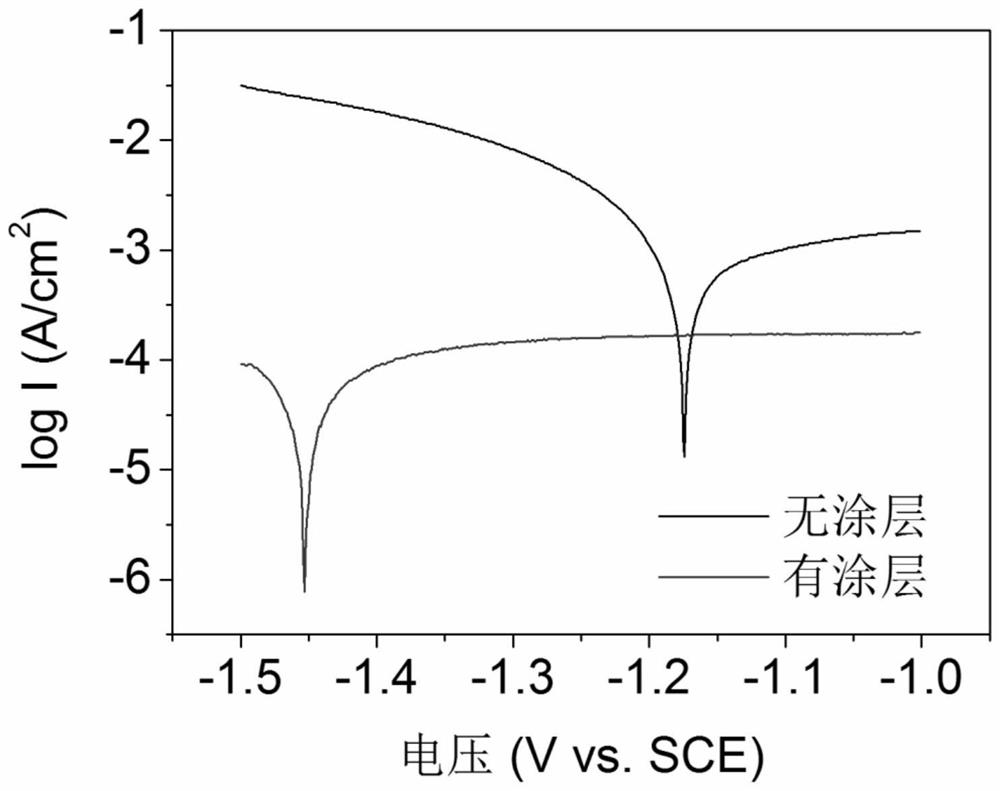

Preparation method of superhydrophobic conductive anticorrosion coating for grounding grid

ActiveCN111662608BPrevent adhesionAvoid corrosionAnti-corrosive paintsEpoxy resin coatingsSuperhydrophobeModified carbon

The invention provides a preparation method of a super-hydrophobic conductive anti-corrosion coating for a grounding grid, comprising etching the titanium-aluminum-carbon MAX phase with LiF and hydrochloric acid to obtain Mxene, putting it and a fluorinating agent into tetrahydrofuran, condensing, pumping After vacuum filtration and drying, the fluorinated modified Mxene was obtained; the fluorinating agent and multi-walled carbon nanotubes were put into tetrahydrofuran, and after condensation, vacuum filtration and drying, the fluorinated modified carbon nanotubes were obtained; the epoxy resin was added Solution A is obtained in tetrahydrofuran; solution B is obtained by dispersing fluorinated modified Mxene and fluorinated modified carbon nanotubes in tetrahydrofuran; the two are mixed, and a curing agent is added, and then coated on the grounding grid, and superhydrophobic is obtained after curing coating. The invention uses the high specific surface area of Mxene to prepare the surface micro-nano structure, and uses the fluorinating agent to provide low surface energy. The micro-nano structure and the low surface energy are coupled to construct a super-hydrophobic surface to prevent the attachment of moisture on the surface of the grounding grid steel and achieve long-term anti-corrosion.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

A kind of crop straw environmental protection flame retardant glueless fiberboard and preparation method thereof

ActiveCN108656305BHigh bonding strengthImprove mechanical propertiesWood working apparatusDomestic articlesFiberZinc borate

The invention relates to an environment-friendly flame-retardant non-adhesive fiberboard of crop straw and a preparation method thereof. The fiberboard is prepared by the following steps that 1 ) wheat straw and sorghum straw are taken to be cut off correspondingly, and the wheat straw and the sorghum straw are soaked in water to obtain a softened material; 2 ) steam explosion is correspondingly carried out on the softened material to obtain wheat straw fiber and sorghum straw fiber; 3 ) nano calcium carbonate, nano zinc oxide are mixed with nano copper oxide, and modifying is carried out toobtain a modified additive A; nano zinc borate, the nano zinc oxide are mixed with the nano copper oxide, and modifying is carried out to obtain a modified additive B; 4 ) the wheat straw fiber and the sorghum straw fiber are mixed with the modified additive A to obtain a core layer mixture; the wheat straw fiber is mixed with the modified additive B to obtain a surface layer mixture; and 5 ) thecore layer mixture is taken as a core layer, the surface layer mixture is taken as a surface layer to be laid and pre-pressed to obtain a slab, after hot-pressing forming and post-treatment are carried out, the environment-friendly flame-retardant non-adhesive fiberboard is obtained. The fiberboard has no formaldehyde release and has good mechanical property, good anti-water, moisture-proof, anti-corrosion and antibacterial properties; and good in fireproof and flame-retardant effects, and suitable for popularization and application.

Owner:霸州市光洋人造板制造有限公司

Construction method of concrete anti-corrosion tooling in splash zone of steel cylindrical revetment structure

ActiveCN106759207BNo pollution in the processLong-term anti-corrosionArtificial islandsUnderwater structuresStructural engineeringTongue and groove

Owner:CHINA CONSTR SIXTH ENG DIV CORP

Anchor hook type composite anti-corrosion metal component and preparation process

ActiveCN103434197BImprove adhesionGood value for moneyLamination ancillary operationsLaminationElectrical polarityZinc

The invention relates to metal surface anticorrosion, and discloses an anchor hook type composite anticorrosive metal member and a making technology thereof. The anticorrosive metal member comprises a metal substrate (2), a metal substrate anchor hook layer (1), an occlusion layer (3) and an anticorrosive layer (4), the metal substrate anchor hook layer (1) comprises flat-headed anchor hooks (11), the metal substrate anchor hook layer (1) has an embedded anchoring connection with the occlusion layer (3), and the anticorrosive layer (4) is arranged outside the occlusion layer (3). The making technology comprises the following steps: 1, making anchor grains having a roughness of 150-1500mum on the surface of the metal substrate; 2, pressing the anchor grains of the metal substrate to form the metal substrate anchor hook layer; and 3, coating to form the occlusion layer. In the invention, the high-roughness anchor hook type anchor grains are made on the base surface, an organic material of polar molecules or a Zn-Al anticorrosive metal binding layer is adopted to make the anchor hook type composite layer, and the composite layer has the characteristics of high adhesion, low energy consumption, high cost performance and long-acting anticorrosion.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com