Heat reflection type epoxy anti-corrosion coating

An epoxy anti-corrosion and heat reflection technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as environmental impact, time-saving, and waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

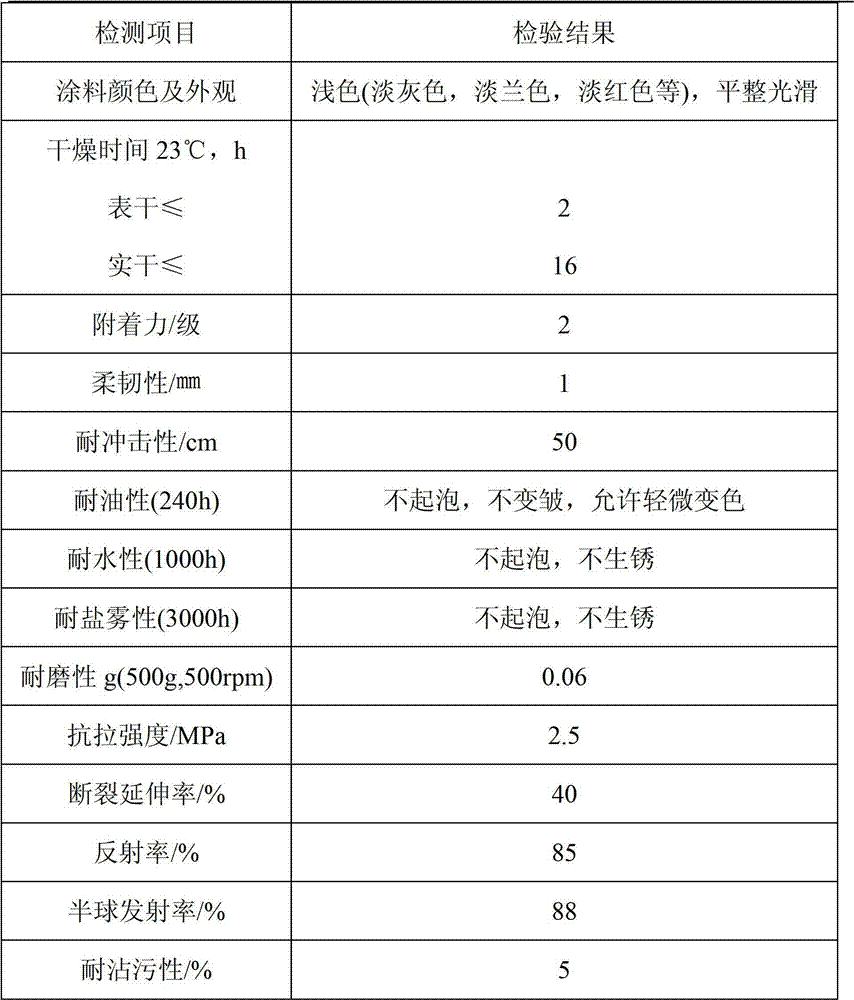

Image

Examples

Embodiment 1

[0037] ingredients

[0038] Component A:

[0039] Epoxy resin (E51): 30%

[0040] Reactive diluent (cardan novolac glyceryl ether): 12.5%

[0042] Titanium dioxide: 7.5%

[0043] A small amount of color paddle (black, yellow, red, etc.)

[0044] Paddle component A for use;

[0045] B component:

[0046] Curing agent (cardanol modified phenolic resin): 20%

[0047] Hollow glass microspheres: 7%

[0048] Infrared radiation powder: 3%

[0049] Rheology modifier (hydrogenated castor oil): 1.0%

[0050] Dispersant (food grade soy lecithin): 0.2%

[0051] Stir and mix component B for later use;

[0052] When the ambient temperature is ≤85%, the ambient temperature is above the dew point of 3°C, the construction temperature range is -5~40°C, and the service time is 45 minutes at 20°C, the minimum painting interval is 4 hours and the maximum is 7 days.

[0053] Application tools can be applied by brush, roller, high pressure airless spray.

...

Embodiment 2

[0056] ingredients

[0057] Component A:

[0058] Epoxy resin (E51): 25%

[0059] Reactive diluent (cardan novolac glyceryl ether): 15%

[0061] Titanium dioxide: 10%

[0062] A small amount of color paddle (black, yellow, red, etc.)

[0063] Paddle component A for use;

[0064] B component:

[0065] Curing agent (cardanol modified phenolic resin): 15%

[0066] Hollow glass microspheres: 5%

[0067] Infrared radiation powder: 5%

[0068]Rheological modifier (organic bentonite): 0.7%

[0069] Dispersant (food grade soy lecithin): 0.3%

[0070] Stir and mix component B for later use;

[0071] When the ambient temperature is ≤85%, the ambient temperature is above the dew point of 3°C, the construction temperature range is -5~40°C, the service time is 45 minutes at 20°C, and the painting interval is as short as 4 hours and as long as 7 days.

[0072] Application tools can be applied by brush, roller, high pressure airless spray.

[0073] B...

Embodiment 3

[0075] ingredients

[0076] Component A:

[0077] Epoxy resin (E51): 35%

[0078] Reactive diluent (cardan novolac glyceryl ether): 10%

[0079] Barium sulfate: 10%

[0080] Titanium dioxide: 5%

[0081] A small amount of color paddle (black, yellow, red, etc.)

[0082] Paddle component A for use;

[0083] B component:

[0084] Curing agent (cardanol modified phenolic resin): 25%

[0085] Hollow glass microspheres: 10%

[0086] Infrared radiation powder: 4%

[0087] Rheology modifier (fumed silica): 0.5%

[0088] Dispersant (food grade soy lecithin): 0.5%

[0089] Stir and mix component B for later use;

[0090] When the ambient temperature is ≤85%, the ambient temperature is above the dew point of 3°C, the construction temperature range is -5~40°C, the service time is 45 minutes at 20°C, and the painting interval is as short as 4 hours and as long as 7 days.

[0091] Application tools can be applied by brush, roller, high pressure airless spray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com