A kind of crop straw environmental protection flame retardant glueless fiberboard and preparation method thereof

A technology for crop straw and fiberboard, applied in the field of straw fiberboard, can solve problems such as hindering the popularization and application of interior decoration materials, lack of strong gluing effect of synthetic resin, no flame retardant effect, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

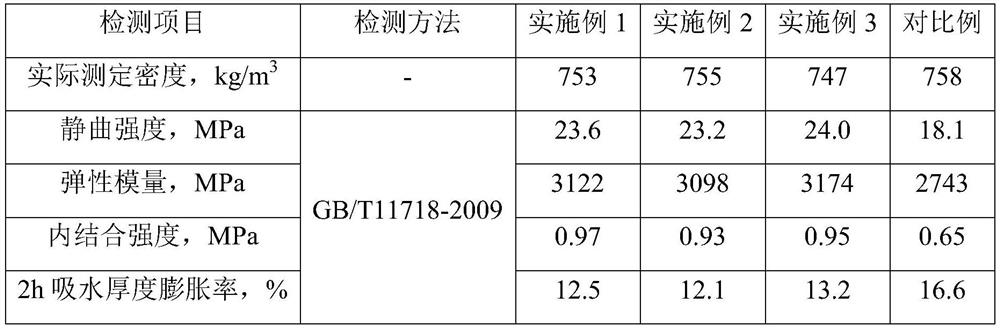

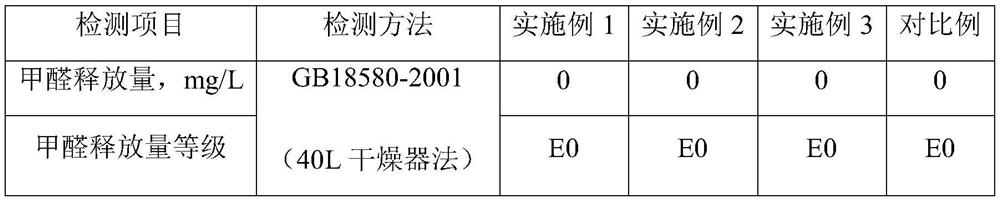

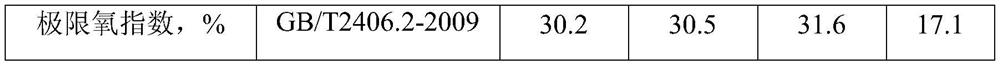

Examples

Embodiment 1

[0046] The crop straw environmental flame retardant flame retardant fiberboard is prepared from the following method:

[0047] 1) Take the dry wheat straw and dry sorghum straw to cut to a length of 20-30 mm, soaked in water for 12h with room temperature, extrusion remove excess moisture, and the water content is between 60% -65% Soft Film and Silica straw softening materials;

[0048] 2) The softening of the wheat straw is softened, the steam temperature is 185 ° C, the blasting pressure is 3.5 MPa, the blast is 2.5 min, and the steam is blasting naturally dry, wormwat straw fiber;

[0049] The sorghum straw softened material is steam blast, the steam temperature is 195 ° C, the blasting pressure is 3.5 MPa, the blasting time is 3.5 min, and the steam is naturally dried after the steam is blasting. Sorghum straw fiber;

[0050] 3) After mixing nanocium carbonate, nano-zinc oxide and nanocarbonate according to a mass ratio of 2.5: 0.3: 0.2, the mass ratio of the nanoparticles and ...

Embodiment 2

[0058] The crop straw environmental flame retardant flame retardant fiberboard is prepared from the following method:

[0059] 1) Take the dry wheat straw and the dry sorghum straw to cut to a length of 20-30 mm, soaked out with water for 14 h, extruded the extra moisture, and the water content between 60% -65%, soft, and Silica straw softening materials;

[0060] 2) The softening of the wheat straw is softened and the steam temperature is 190 ° C, the blasting pressure is 3.0 MPa, the blast is 3.0 min, and the steam is blasting naturally dry, wormwat straw fiber;

[0061] The sorghum straw softened material is steam blast, the steam temperature is 200 ° C, the blasting pressure is 3.0 MPa, the blasting time is 4.0min, the steam is naturally dried, and the sorghum straw fiber;

[0062] 3) After mixing nano carbonate, nano-zinc oxide and nanocarbonate according to the mass ratio of 2.5: 0.35: 0.15, the mass ratio of the nanoparticles and the silane coupling agent is 3: 1. After ult...

Embodiment 3

[0070] The crop straw environmental flame retardant flame retardant fiberboard is prepared from the following method:

[0071] 1) Take the drying wheat straw and the dry sorghum straw separately cut to a length of 20-30 mM, soaked out with a room temperature for 16 h, extruded the excess moisture, and the water content between 60% -65% softening material and Silica straw softening materials;

[0072] 2) The softening of the wheat straw is softened, the steam temperature is 190 ° C, the blasting pressure is 3.2 MPa, the blasting time is 3.0 min, and the steam blasts are naturally dried, and wheat straw fiber;

[0073] The sorghum straw softened material is steam blasting, the steam temperature is 195 ° C, the blasting pressure is 3.2MPa, the blasting time is 3.5 min, the steam is naturally dried, and the sorghum straw fiber;

[0074] 3) After mixing nanocium carbonate, nano-zinc oxide and nanocarbonate in mass ratio of 2.5: 0.4: 0.1, the mass ratio of the nanoparticles and the sila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com