Anchor hook type composite anti-corrosion metal component and preparation process

A metal component and anchor hook type technology, which is applied in the field of anchor hook type composite anti-corrosion metal components and preparation technology, can solve the problems of difficult coating or composite, brittleness, refractoriness and non-polar difficult coating of inorganic materials. , to achieve the effect of high cost performance, high adhesion and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

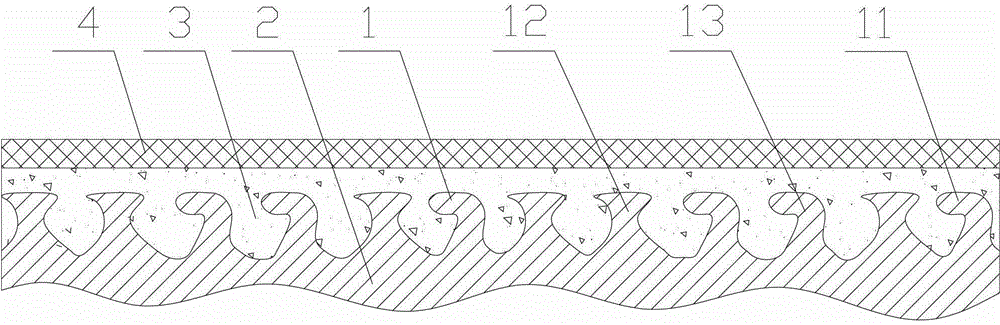

[0021] Anchor-hook composite anti-corrosion metal components, such as figure 1 As shown, it includes a metal substrate 2, a metal substrate anchor layer 1, an occlusal layer 3, and an anti-corrosion layer 4. The surface roughness of the metal substrate 2 is 840 μm, and the surface of the metal substrate 2 is provided with a metal substrate The anchor hook layer 1, the metal base anchor hook layer 1 includes a flat anchor hook 11, the metal base anchor hook layer 1 is embedded and anchored with the occlusal layer 3, and an anti-corrosion layer 4 is arranged outside the occlusal layer 3.

[0022] The flat-headed anchor hook 11 has a mushroom-shaped anchor pattern 12 and a hook-shaped anchor pattern 13. The cross-section of the mushroom-shaped anchor pattern 12 is a "T" shape, and the cross-section of the hook-shaped anchor pattern 13 is a "7" shape.

[0023] The metal substrate 2 is made of one or more composite materials of steel, cast iron, copper, and aluminum. The ratio of ...

Embodiment 2

[0029] Anchor-hook composite anti-corrosion metal components, such as figure 1 As shown, it includes a metal substrate 2, a metal substrate anchor hook layer 1, an occlusal layer 3, and an anti-corrosion layer 4. The surface roughness of the metal substrate 2 is 1243 μm, and the surface of the metal substrate 2 is provided with a metal substrate The anchor hook layer 1, the metal base anchor hook layer 1 includes a flat anchor hook 11, the metal base anchor hook layer 1 is embedded and anchored with the occlusal layer 3, and an anti-corrosion layer 4 is arranged outside the occlusal layer 3.

[0030] The flat-headed anchor hook 11 has a mushroom-shaped anchor pattern 12 and a hook-shaped anchor pattern 13. The cross-section of the mushroom-shaped anchor pattern 12 is a "T" shape, and the cross-section of the hook-shaped anchor pattern 13 is a "7" shape.

[0031] The metal substrate 2 is made of one or more composite materials of steel, cast iron, copper, and aluminum. The met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com