Preparation method of superhydrophobic conductive anticorrosion coating for grounding grid

A conductive anti-corrosion and super-hydrophobic technology, applied in conductive coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as grounding grid corrosion, and achieve the effects of inhibiting corrosion, preventing moisture adhesion, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

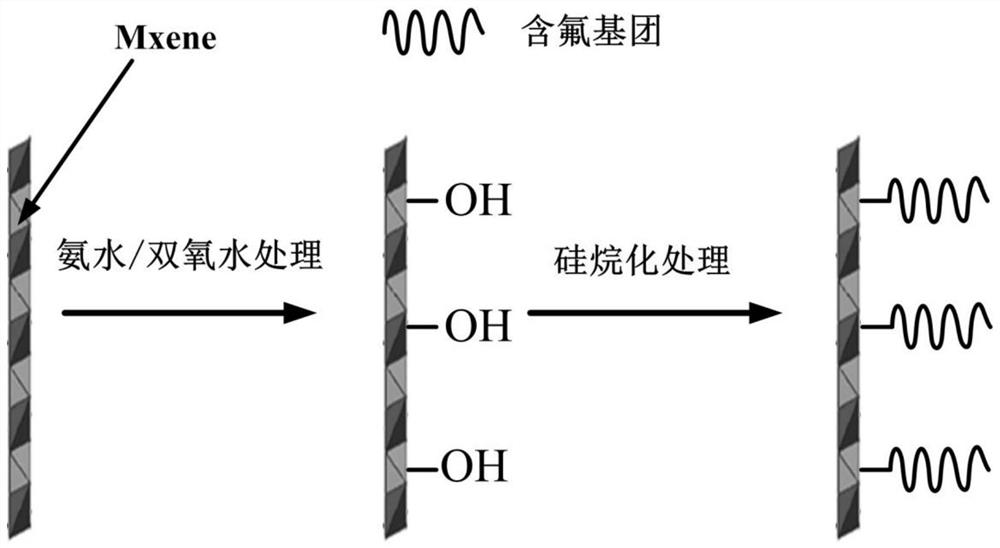

[0039] The present embodiment relates to a method for preparing a superhydrophobic conductive anti-corrosion coating for grounding mesh, comprising the following steps:

[0040] Step 1: LiF and hydrochloric acid were used to etch the titanium-aluminum-carbon MAX phase and prepare Méne. Preferably, the concentration of hydrochloric acid is 5 ~ 12mol / L. Among them, the titanium-aluminum carbon MAX phase is Ti 2 C。 The specific step is to slowly dissolve lithium fluoride in hydrochloric acid, stir for 5 minutes, and slowly add 1g Ti 2 AlC, join Ti 2 AlC takes ten minutes, and slowly the hydrochloric acid will corrode the Ti 2 Aluminum in AlC. Stir at room temperature for 24 hours, then wash and centrifuge with deionized water at a centrifugal speed of 3500 rpm, each centrifugation for 5 min, about 6-8 centrifugations, until the pH of the solution is greater than 6. Collect the pellet, dissolve the pellet in water, and sonicate for 3 hours in an atmosphere protected by argon. The la...

Embodiment 2

[0048] The present embodiment relates to a preparation method of superhydrophobic conductive anti-corrosion coating for grounding mesh, which is the specific application under Example 1.

Embodiment 21

[0050] Step 1: Apply LiF and hydrochloric acid to etch the titanium-aluminum-carbon MAX phase and prepare Méne. Specifically, 0.67g of lithium fluoride was slowly dissolved in 10mL of hydrochloric acid at a concentration of 5mol / L, stirred for 5 minutes, and 1g ti was added slowly 2 AlC, join Ti 2 AlC takes ten minutes. Stir at room temperature for 24 hours, and then wash and centrifuge with deionized water, centrifugation speed is 3500 rpm, each centrifugation is 5 min, about 6-8 centrifugations, so that the PH of the solution is greater than 6. Collect the precipitation, dissolve in 100 mL of water, under an atmosphere protected by argon, sonicate for 3 hours. The last 3500 rpm, centrifugation for one hour, the supernatant is collected, and the centrifuged solid is Méne.

[0051] Step two, the 0.2g step 1 obtained Mxene into the ammonia / hydrogen peroxide mixed solution (wherein, ammonia and hydrogen peroxide take 50ml each, the concentration of ammonia is 25wt%, the concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com