Long-acting weather-resistant chlorine salt corrosion-resistant polyester powder coating and preparation method thereof

A technology of polyester powder and powder coating, which is applied in the direction of powder coating, polyester coating, anti-corrosion coating, etc. It can solve the problems of guardrails, bridges, low cross-linking density, poor water resistance and resistance to inorganic salt penetration, etc. Achieve excellent low temperature flow properties, good linear structure and high curing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

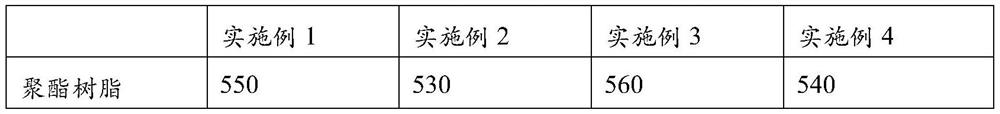

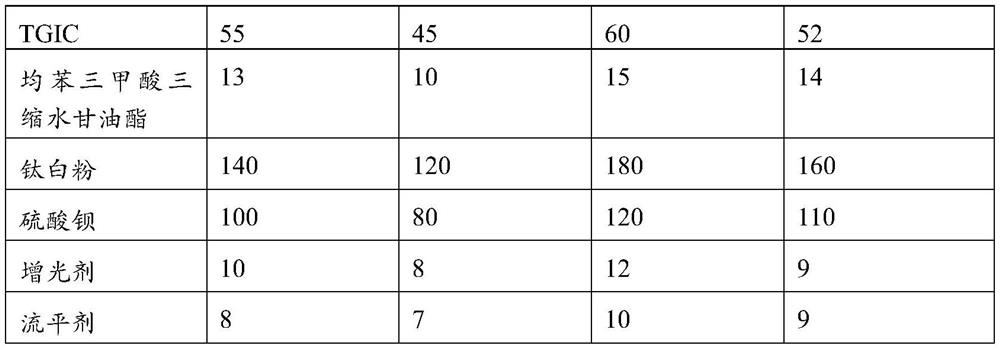

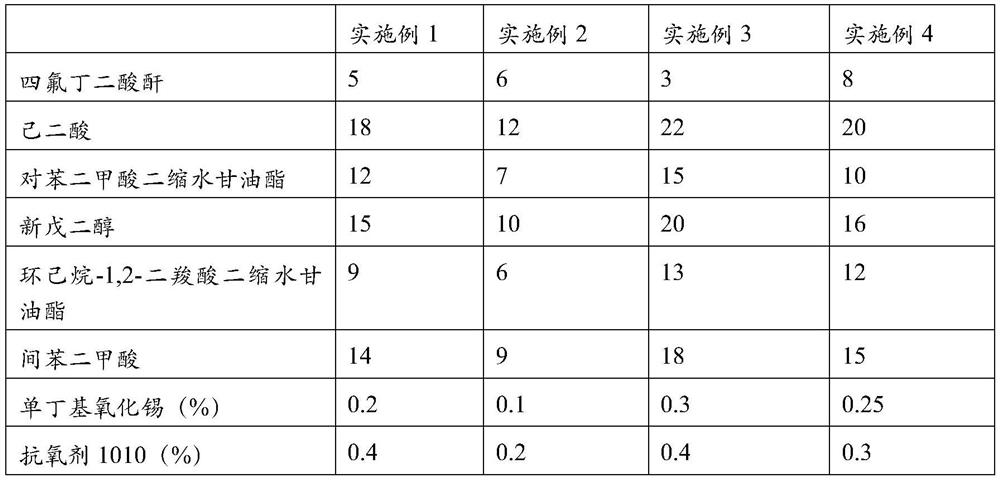

Examples

Embodiment 1

[0054] The preparation method of long-acting weather resistance, anti-chlorine salt corrosion type polyester powder coating comprises the following steps:

[0055] S1: Add the formulated amount of TGIC and trimesic acid triglycidyl ester into the reaction kettle, and gradually heat it to 107°C. After the materials are completely melted, stir and let them mix and react for 30 minutes, discharge while hot, cool, and crush into 60 Obtain modified curing agent powder;

[0056] S2: Weigh the modified curing agent powder obtained in S1 and the polyester resin of the formula amount into the high-speed mixer, start the mixing device, and mix at a high speed for about 20 minutes;

[0057] S3: After the main raw materials in S2 are mixed evenly, put them into a twin-screw extruder for melt extrusion, the temperature of the extrusion section is about 125°C, and the screw speed is 545rpm; then cooled and crushed into 4mm particles to obtain a primary extruded material ;

[0058] S4: Add...

Embodiment 5

[0079] Coating coating preparation: Spray the prepared powder coating on the surface-treated tinplate substrate with an electrostatic spray gun, with a film thickness of about 120 μm, and fully cure at 160°C / 20min to obtain the coating coating.

[0080] Coating index detection is based on GB / T 21776-2008 "Guidelines for Testing Standards for Powder Coatings and Coatings"; weather resistance test is based on GB / T 1865-2009 "Paints and Varnishes Artificial Weathering and Artificial Radiation Exposure Filtered Xenon Arc Radiation" in Table 4 A specified step program continuous artificial weathering test 700h. Adhesion grade is based on GB / T9286-1998 "Cross-cut test of paint and varnish film"; chlorine salt corrosion resistance adopts soaking method. , the surface is gently rinsed with running water, and the surface of the coating film is observed for discoloration, blistering, cracking, and peeling off; the salt spray test is carried out according to GB / 1771-2007 "Determination o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com