Spinnable alumina sol, its preparation method and alumina continuous fiber

A technology of continuous fiber and aluminum sol, which is applied in the field of continuous alumina fiber, can solve problems affecting the mechanical properties of fibers, achieve good stability, good linear structure, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment relates to the preparation of a continuous alumina fiber. Firstly, spinnable aluminum sol is prepared, followed by concentration and defoaming, then dry spinning, and finally continuous collection.

[0034] The specific operation process is as follows:

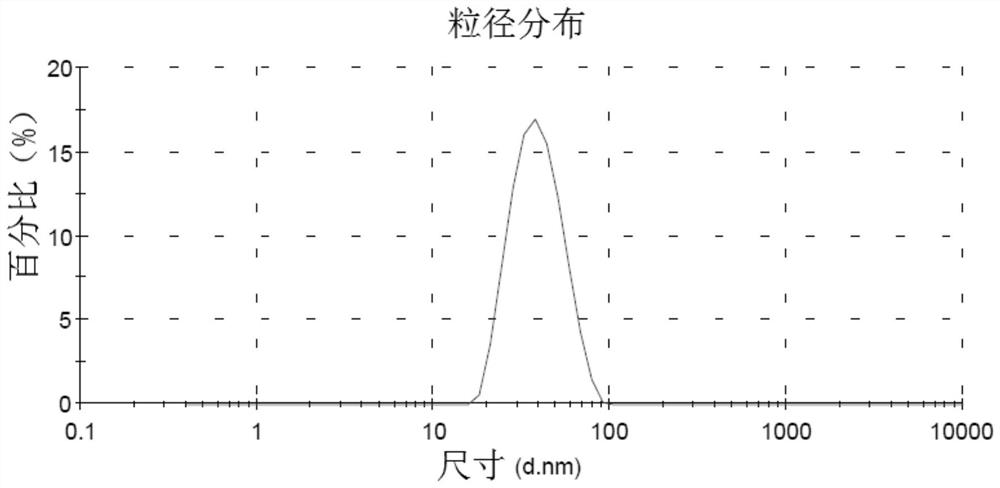

[0035] First, mix pseudo-boehmite and deionized water in a ratio of 2:8 by weight, then add nitric acid in a certain proportion, adjust the pH to 4, stir evenly at room temperature, and then place it in a hydrothermal reaction kettle at a temperature of 100°C , the reaction time is 1h under the condition of pressure 0.5MPa, and the spinnable aluminum sol is prepared. The viscosity of the prepared spinnable aluminum sol is 5mpa·s, the average particle size of the colloid is 35nm, and the particle size distribution is as follows: figure 1 shown;

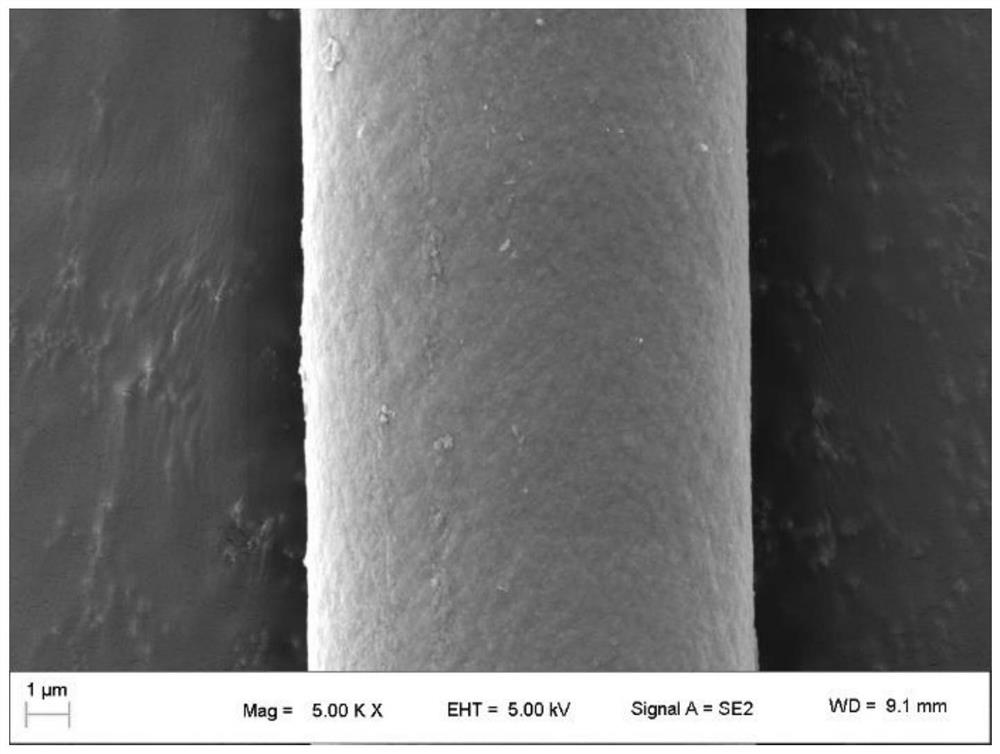

[0036] Next, the prepared spinnable aluminum sol was concentrated and defoamed, the solid content was controlled at 50%, and the viscosity reached 95pa·s at thi...

Embodiment 2

[0040] Compared with Example 1, only the hydrothermal reaction temperature was changed in the preparation process of the spinnable aluminum sol, and the hydrothermal reaction temperature was controlled to be 120°C. 52nm;

[0041] Then concentrate and defoam the spinnable aluminum sol, control the solid content to 50%, and the viscosity at this time is 132pa·s;

[0042] Finally, dry spinning, control spinning temperature 60°C, spinning pressure 0.5MPa, tunnel temperature 40°C, spinning speed 200m / min, spinneret hole used in dry spinning is 500 holes, hole diameter 0.03mm ; The obtained alumina continuous fiber has a diameter of 22 μm and a continuous spinning length of 1300 m.

Embodiment 3

[0044] Compared with Example 1, only the hydrothermal reaction pressure was changed in the preparation process of the spinnable aluminum sol, and the hydrothermal reaction pressure was controlled at 0.9MPa. 43nm;

[0045] Then concentrate and defoam the spinnable aluminum sol, control the solid content to 50%, and the viscosity at this time is 116pa·s;

[0046] Finally, dry spinning, control spinning temperature 60°C, spinning pressure 0.5MPa, tunnel temperature 40°C, spinning speed 200m / min, spinneret hole used in dry spinning is 500 holes, hole diameter 0.03mm The obtained alumina continuous fiber has a diameter of 20 μm and a continuous spinning length of 1700 m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com