A kind of preparation method of scale inhibitor

A scale inhibitor, polyaspartic acid technology, applied in chemical instruments and methods, scale removal and water softening, water/sludge/sewage treatment, etc., can solve the problem of low scale inhibition efficiency, environmental harm and low production cost and other problems, to achieve the effect of not destroying the ecological environment, broadening the scope of application, good biodegradability and water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

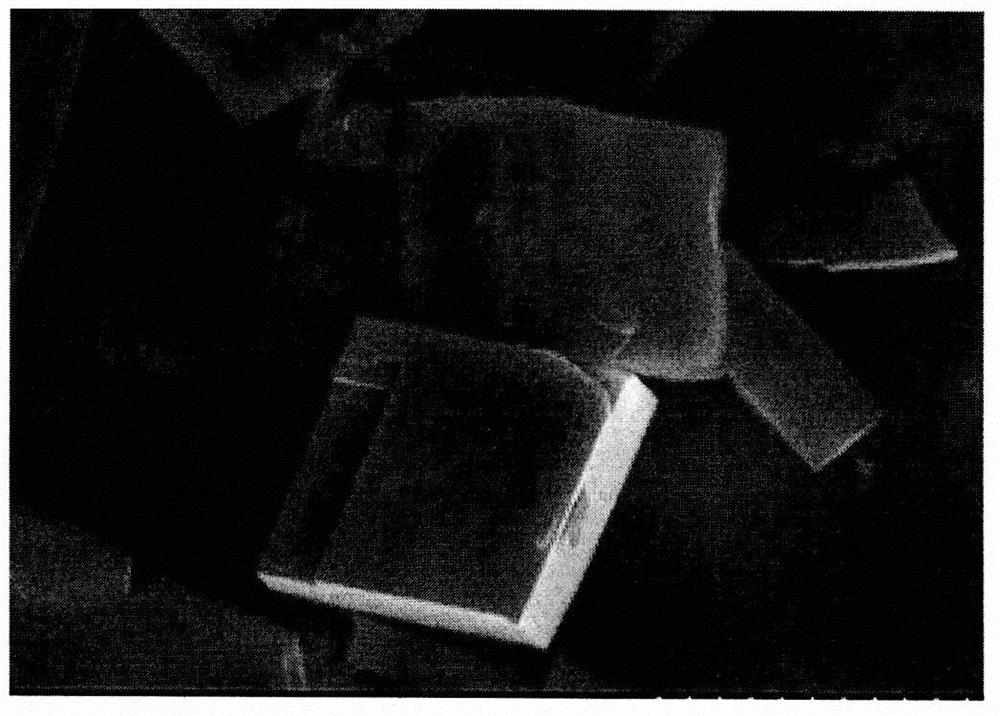

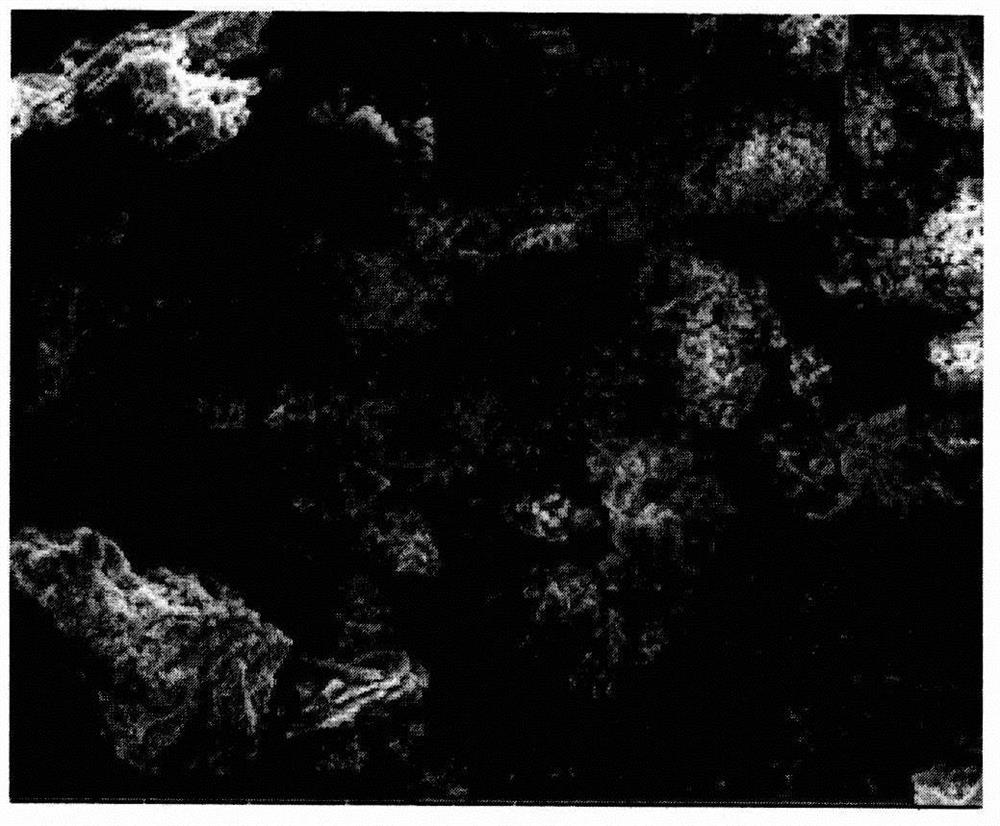

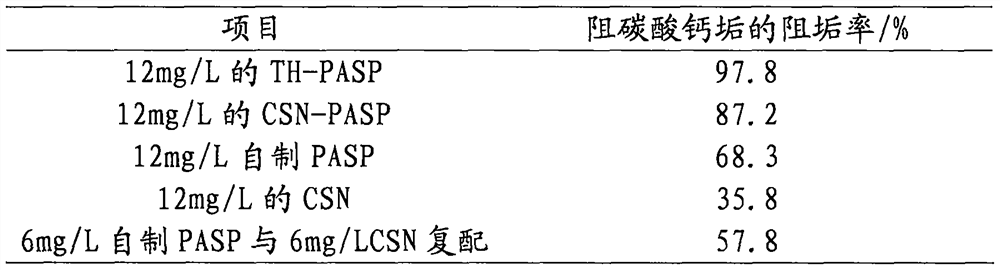

Image

Examples

Embodiment 1

[0017] A. Preparation of polyaspartic acid (PASP)

[0018] ① Synthesis of PSI: Add 9.8g maleic anhydride and 20mL deionized water into a three-neck flask, stir and heat to 84°C, then slowly add ammonia water according to the mass ratio of maleic anhydride to ammonia water 1:1.25. After hydrolysis for 1.5h, distillation under reduced pressure gave white flaky crystals of maleimide. Add deionized water dropwise until the maleimide just dissolves, and then conduct a polycondensation reaction at 200°C for 40 minutes to obtain a brown-red sticky substance—polysuccinimide (PSI).

[0019] ② Synthesis of PASP: PSI was just dissolved in deionized water, and then hydrolyzed by adding 4 mL of 3 mol / L sodium hydroxide in a water bath at a temperature of 65 ° C for 45 min. The measured pH is about 9.5, neutralized with hydrochloric acid to make pH=7. Wash with absolute ethanol, filter and dry to obtain polyaspartic acid (PASP).

[0020] B. Preparation of polyaspartic acid derivative sca...

Embodiment 2

[0023] A. Preparation of polyaspartic acid (PASP)

[0024] ① Synthesis of PSI: Add 19.6g maleic anhydride and 40mL deionized water into a three-neck flask, stir and heat to 85°C, then slowly add ammonia water according to the mass ratio of maleic anhydride to ammonia water 1:1.25. Hydrolyzed for 2h and distilled under reduced pressure to obtain white flaky crystals of maleimide. Add deionized water dropwise until the maleimide just dissolves, and then conduct a polycondensation reaction at 210°C for 50 minutes to obtain a brown-red sticky substance—polysuccinimide (PSI).

[0025] ② Synthesis of PASP: PSI was just dissolved in deionized water, and then hydrolyzed by adding 8 mL of 3 mol / L sodium hydroxide in a water bath at a temperature of 70 °C for 50 min. The measured pH is about 10, neutralized with hydrochloric acid to make pH=7. Wash with absolute ethanol, filter and dry to obtain polyaspartic acid (PASP).

[0026] B. Preparation of polyaspartic acid derivative scale i...

Embodiment 3

[0029] A. Preparation of polyaspartic acid (PASP)

[0030] ① Synthesis of PSI: Add 29.4g maleic anhydride and 60mL deionized water into a three-necked flask, stir and heat to 86°C, then slowly add ammonia water according to the mass ratio of maleic anhydride to ammonia water 1:1.25. Hydrolyzed for 3h and distilled under reduced pressure to obtain white flaky crystals of maleimide. Add deionized water dropwise until the maleimide just dissolves, and then conduct a polycondensation reaction at 220°C for 60 minutes to obtain a brown-red sticky substance—polysuccinimide (PSI).

[0031] ② Synthesis of PASP: PSI was just dissolved in deionized water, and then hydrolyzed by adding 12 mL of 3 mol / L sodium hydroxide in a water bath at a temperature of 75 °C for 55 min. The measured pH is about 10.5, neutralized with hydrochloric acid to make pH=7. Wash with absolute ethanol, filter and dry to obtain polyaspartic acid (PASP).

[0032] B. Preparation of polyaspartic acid derivative sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com