Anti-corrosion paste and preparation method thereof

A technology of anti-corrosion paste and surfactant, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problem that the steel structure anti-corrosion paste cannot be attached and only acts on the surface layer, achieving high crack followability, convenient construction, and follow-up excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

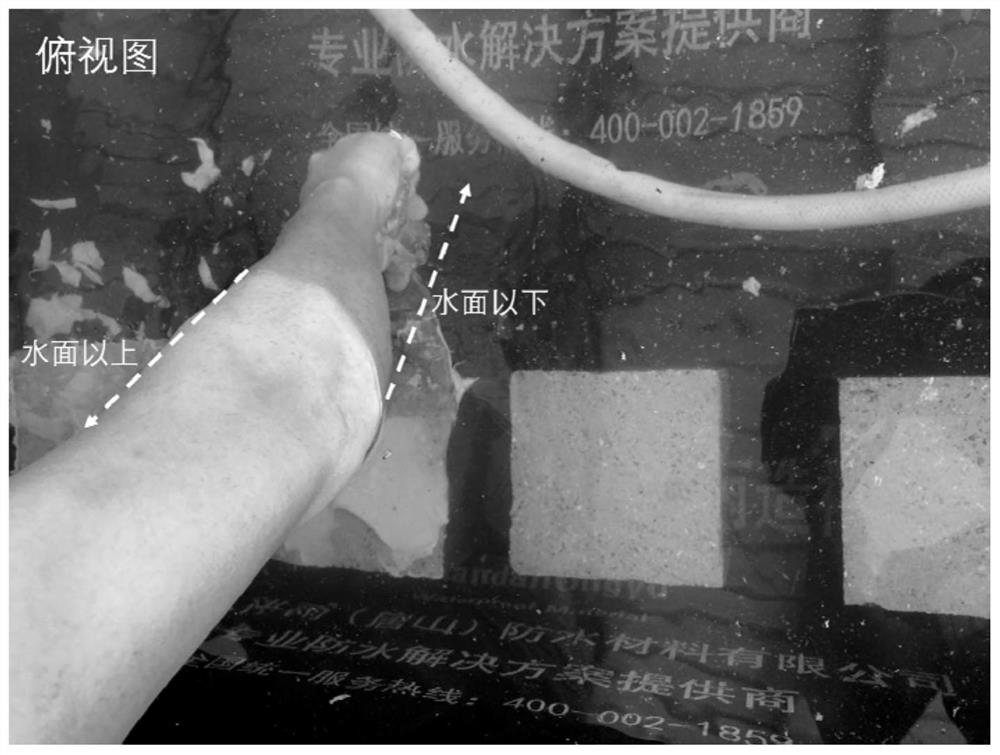

Method used

Image

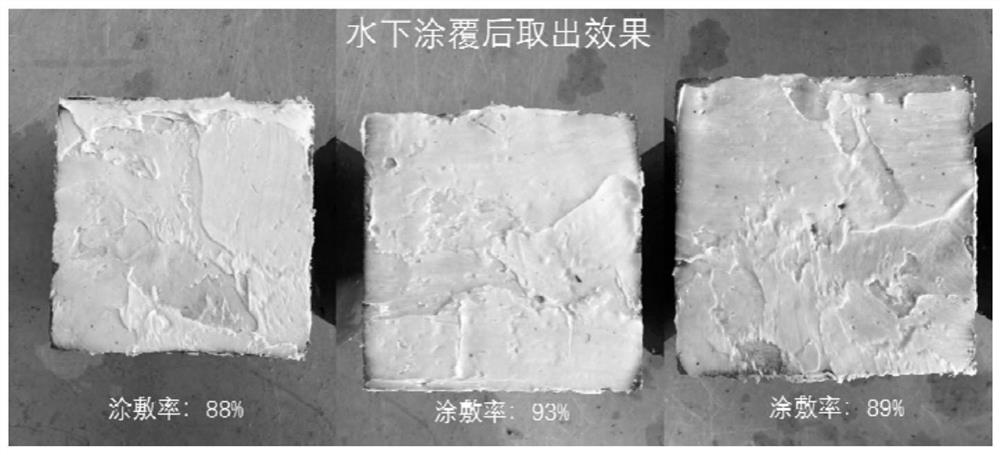

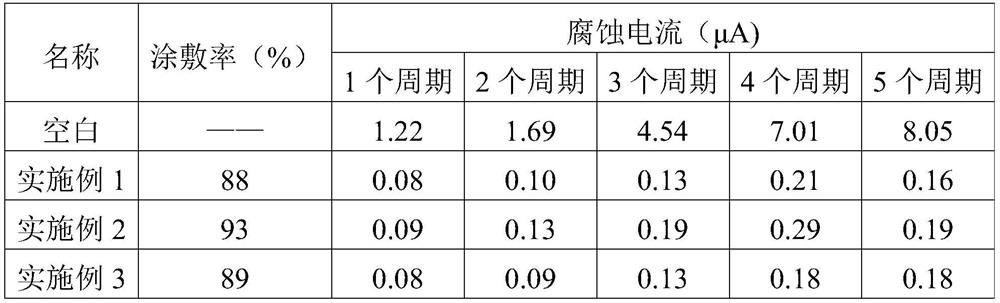

Examples

Embodiment 1

[0025] By weight percentage, the proportion of materials is as follows:

[0026] Base grease (soap base grease, hydrocarbon base grease, inorganic grease, organic grease) 35%, high penetration rust inhibitor (alcohol amine rust inhibitor, imidazoline rust inhibitor, sodium benzoate rust inhibitor) 5%, surfactant [ Anions (sodium dodecylsulfate and sodium dodecylbenzenesulfonate), cations (alkyltrimethylammonium salts, dialkyldimethylammonium salts, alkyldimethylbenzyl quaternary ammonium salts) ), nonionics (sorbitan fatty acid ester, polyoxyethylene sorbitan fatty acid ester, alkylphenol and ethylene oxide condensate)] 20%, thickener (2000 mesh heavy calcium carbonate, Mica powder, silica powder) 30%, plasticizer (white oil, phthalate, chlorinated paraffin) 10%.

[0027] The preparation process is as follows: base oil, high-permeability rust inhibitor, surfactant, thickener and plasticizer are weighed according to the ratio, and added to the double planetary reactor in seque...

Embodiment 2

[0029] By weight percentage, the proportion of materials is as follows:

[0030] Base grease (soap base grease, hydrocarbon base grease, inorganic grease, organic grease) 80%, high penetration rust inhibitor (alcohol amine rust inhibitor, imidazoline rust inhibitor, sodium benzoate rust inhibitor) 0.5%, surfactant [ Anions (sodium dodecylsulfate and sodium dodecylbenzenesulfonate), cations (alkyltrimethylammonium salts, dialkyldimethylammonium salts, alkyldimethylbenzyl quaternary ammonium salts) ), nonionics (sorbitan fatty acid ester, polyoxyethylene sorbitan fatty acid ester, alkylphenol and ethylene oxide condensate)] 0.5%, thickener (500 mesh ground calcium carbonate, Mica powder, silica powder) 18%, plasticizer (white oil, phthalate, chlorinated paraffin) 1%.

[0031] The preparation process is as follows: base grease, high-permeability rust inhibitor, surfactant, thickener and plasticizer are weighed according to the ratio, and added to the double planetary reactor in ...

Embodiment 3

[0033] By weight percentage, the proportion of materials is as follows:

[0034]Base grease (soap base grease, hydrocarbon base grease, inorganic grease, organic grease) 55%, high penetration rust inhibitor (alcohol amine rust inhibitor, imidazoline rust inhibitor, sodium benzoate rust inhibitor) 3%, surfactant [ Anions (sodium dodecylsulfate and sodium dodecylbenzenesulfonate), cations (alkyltrimethylammonium salts, dialkyldimethylammonium salts, alkyldimethylbenzyl quaternary ammonium salts) ), nonionics (sorbitan fatty acid ester, polyoxyethylene sorbitan fatty acid ester, alkylphenol and ethylene oxide condensate)] 5%, thickener (800 mesh heavy calcium carbonate, Mica powder, silica powder) 27%, plasticizer (white oil, phthalate, chlorinated paraffin) 10%.

[0035] The preparation process is as follows: base grease, high-permeability rust inhibitor, surfactant, thickener and plasticizer are weighed according to the proportion, and then added to the double planetary reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com