Concrete anticorrosive tooling construction method for splash zone of steel cylindrical bank protection structure

A construction method and technology of steel cylinders, which are applied in basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of hidden safety hazards, corrosion, affecting the subsequent development and utilization of artificial islands, and achieve convenient installation, The effect of improving safety and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

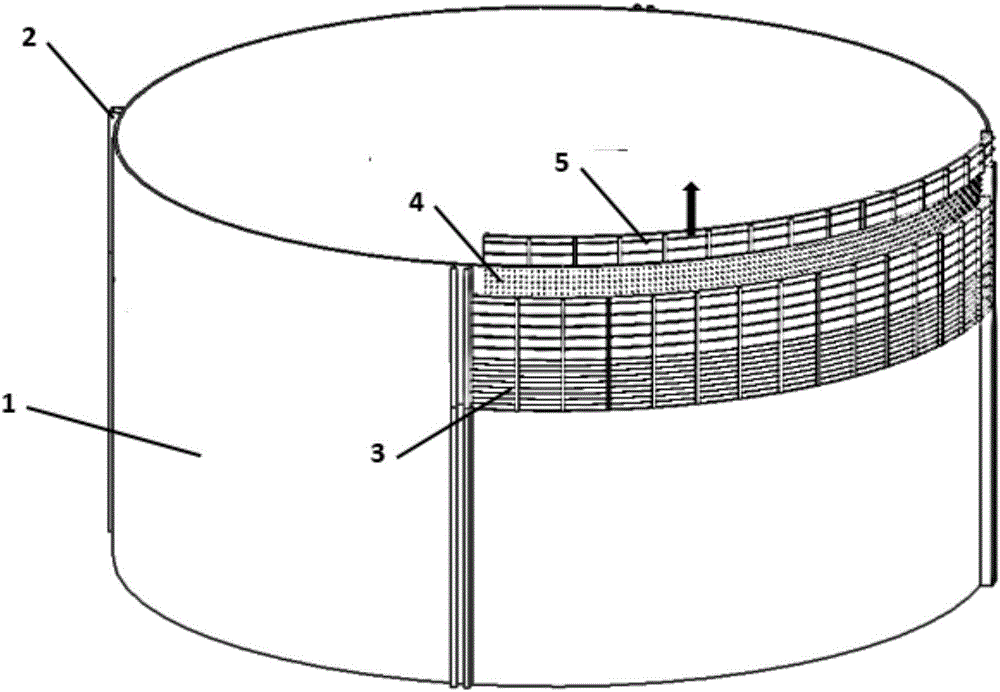

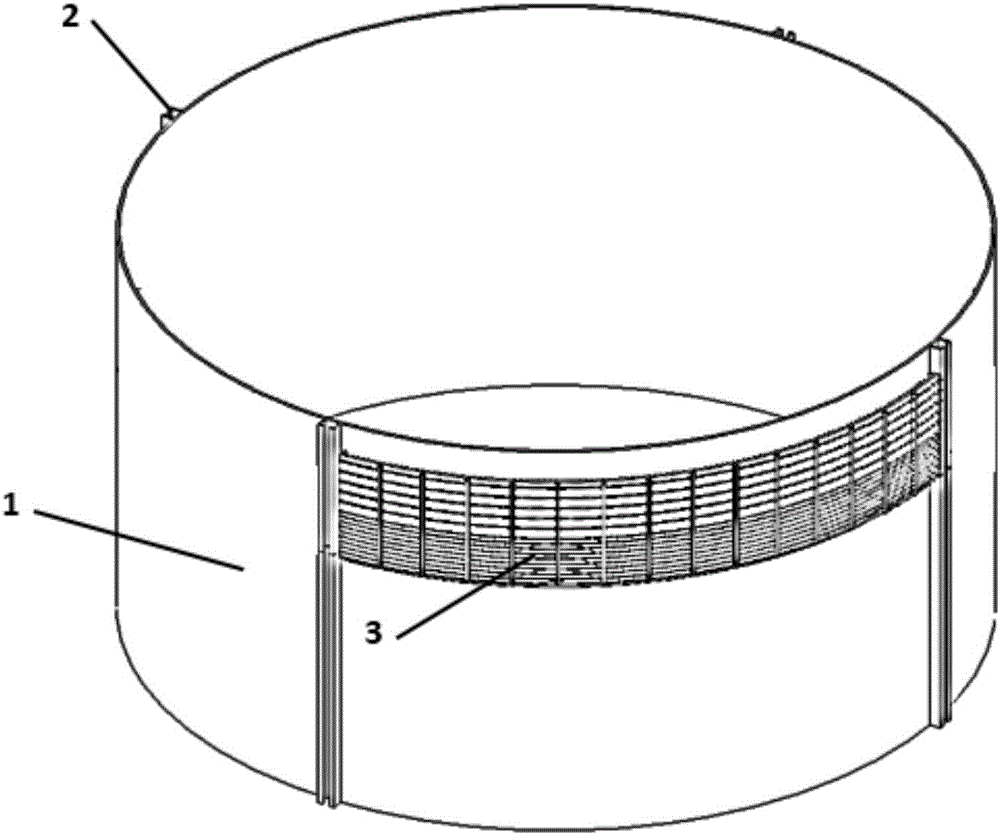

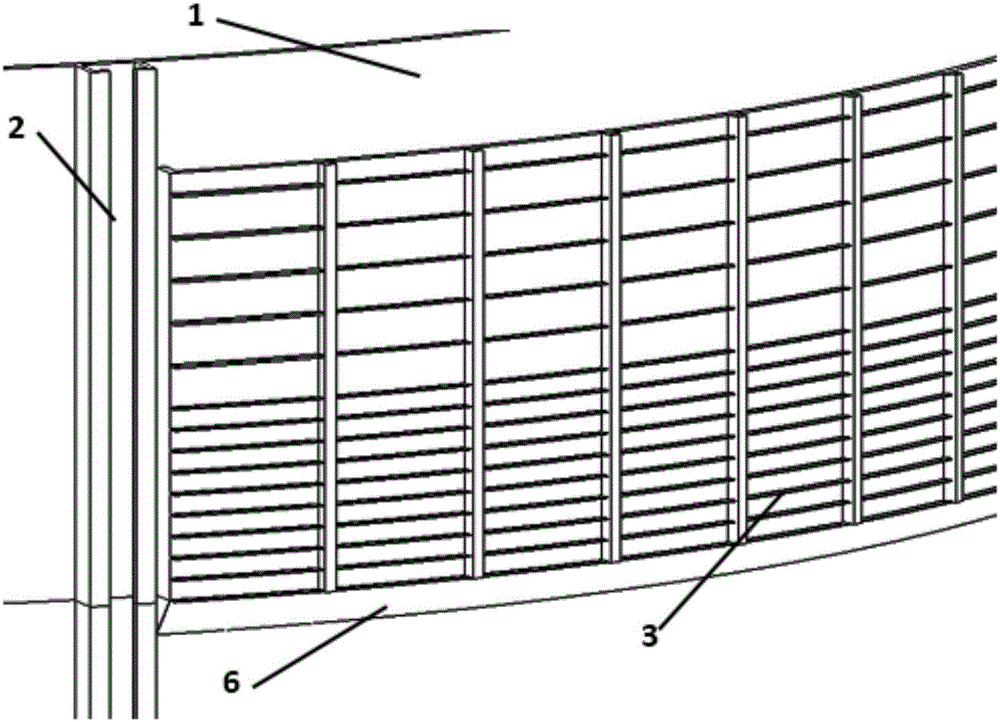

[0039] (1) Fix the shear connection structure on the outer wall of the splash area of the steel cylindrical bank revetment structure with a tongue and groove structure, the distance between the top of the shear connection structure and the top of the revetment structure is 15cm, so The height of the shear connection structure described above is 4.8m;

[0040] (2) Weld the bottom mold support plate in the circumferential range of the revetment structure splash zone at the bottom of the shear connection structure at a predetermined distance;

[0041] (3) An arc-shaped fixed formwork is installed at the bottom of the shear connection structure, and a horizontally arranged arc-shaped bottom wall is welded at the bottom of the fixed formwork, and the bottom wall of the fixed formwork is connected to the outer wall of the revetment structure by welding and the fixed formwork The bottom wall and the support plate are welded and fixed, and the left and right side walls of the fixed ...

Embodiment 2

[0047] (1) Fix the shear connection structure on the outer wall of the splash area of the steel cylindrical bank revetment structure with a tongue and groove structure, the distance between the top of the shear connection structure and the top of the revetment structure is 20cm, so The height of the shear connection structure described above is 5m;

[0048] (2) Weld the bottom mold support plate in the circumferential range of the revetment structure splash zone at the bottom of the shear connection structure at a predetermined distance;

[0049] (3) An arc-shaped fixed formwork is installed at the bottom of the shear connection structure, and a horizontally arranged arc-shaped bottom wall is welded at the bottom of the fixed formwork, and the bottom wall of the fixed formwork is connected to the outer wall of the revetment structure by welding and the fixed formwork The bottom wall and the support plate are welded and fixed, and the left and right side walls of the fixed fo...

Embodiment 3

[0055] (1) Fix the shear connection structure on the outer wall of the splash area of the steel tubular bank revetment structure with a tongue and groove structure, the distance between the top of the shear connection structure and the top of the revetment structure is 18cm, so The height of the shear connection structure described above is 4.5m;

[0056] (2) Weld the bottom mold support plate in the circumferential range of the revetment structure splash zone at the bottom of the shear connection structure at a predetermined distance;

[0057] (3) An arc-shaped fixed formwork is installed at the bottom of the shear connection structure, and a horizontally arranged arc-shaped bottom wall is welded at the bottom of the fixed formwork, and the bottom wall of the fixed formwork is connected to the outer wall of the revetment structure by welding and the fixed formwork The bottom wall and the support plate are welded and fixed, and the left and right side walls of the fixed form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com