Gelatin sponge core laminating and bonding device for tire filling

A technology of bonding device and sponge glue, which is applied in tires, applications, household appliances, etc., can solve the problems of difficult connection at the interface, labor and time-consuming, and easy problems in product quality, so as to achieve easy promotion and implementation, convenient use, and good quality. The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

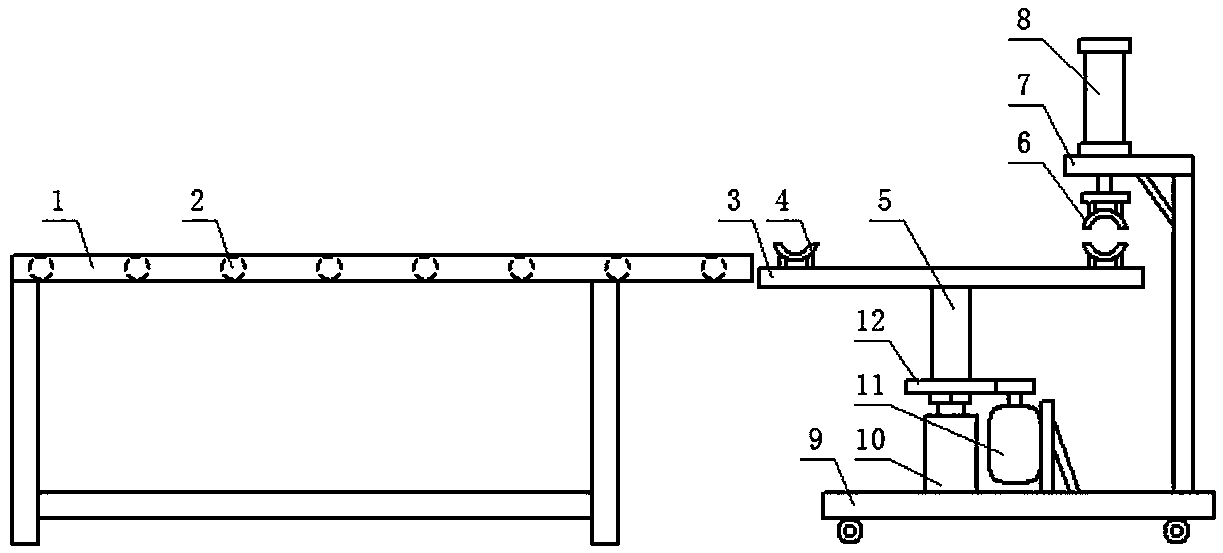

[0016] Example: see figure 1 , in the figure, 1-feeding frame, 2-rotating roller, 3-table, 4-lower arc pallet, 5-rotation shaft, 6-upper arc pressure plate, 7-support frame, 8-lifting pressure cylinder, 9-base, 10-rotary seat, 11-drive motor, 12-transmission pair.

[0017] The sponge rubber core pressing and bonding device for filling tires includes a feeding mechanism and a pressing mechanism. There is an endless belt, and one of the rotating rollers 2 is connected with the rotating motor, which is not shown in the figure; the pressing mechanism includes a frame and a lifting pressure cylinder 8, the upper end of the frame is a workbench 3, and the lower end is a base 9, on which a There is a rotating base 10, the lower end of the workbench is provided with a rotating shaft 5, and the rotating shaft 5 is inserted into the rotating base 10, and the two are connected in a rotating manner. One side of the base 9 is provided with a support frame 7, and the upper end of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com