Multi-cell metal-based carbon fiber composite thin-walled energy absorbing structure and preparation technique thereof

An energy-absorbing structure and carbon fiber technology, applied in bumpers and other directions, can solve the problems of deformation coordination and low guiding energy-absorbing structure, and achieve the effects of strong deformation coordination and guidance, light structure and flexible design scheme.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] This embodiment mainly relates to the effect of the number of carbon fiber inner tubes in the multicellular metal-based carbon fiber composite thin-wall energy-absorbing structure on the energy-absorbing effect.

[0053] The multicellular metal-based carbon fiber structure is composed of a 6061-T4 aluminum alloy outer tube and a carbon fiber inner tube. Specifically, it can be divided into three different design schemes: scheme A, scheme B, and scheme C.

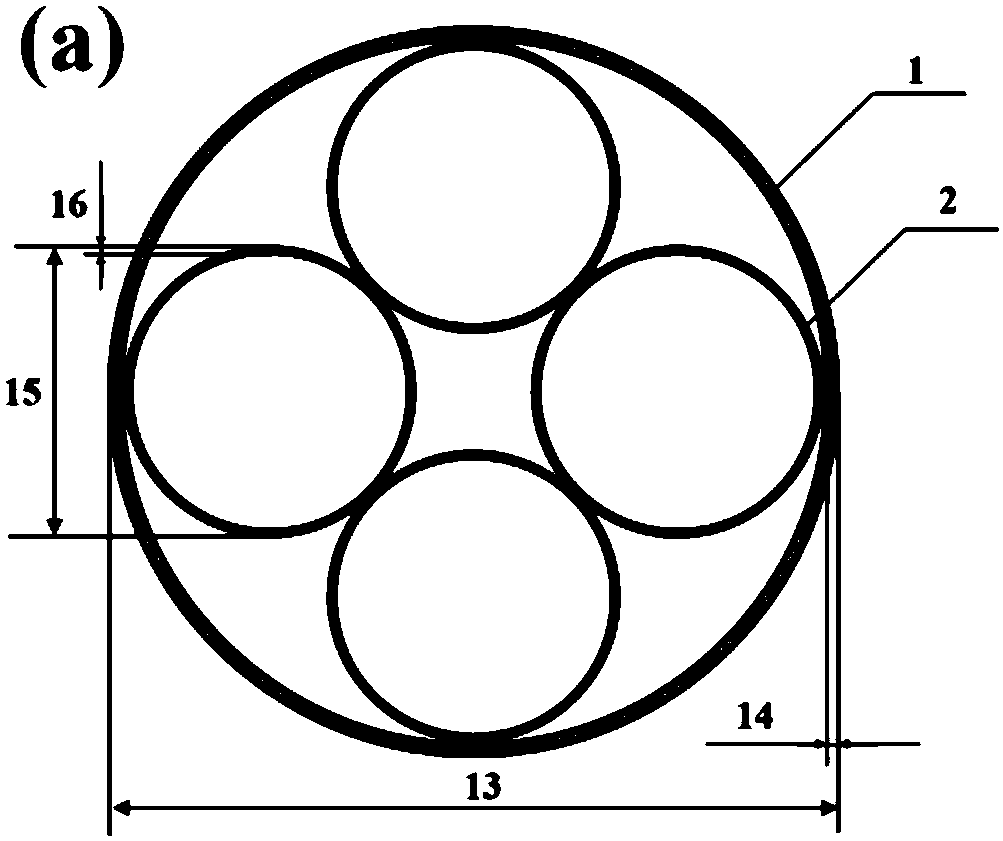

[0054] Among them, the height I38 of the multicellular structure I37 in scheme A is 80mm, the number of carbon fiber inner tubes I"40 in the multicellular structure I37 is N=3, and the thickness of the aluminum alloy outer tube I"39 in the multicellular structure I37 is 2mm. The outer diameter I'41 of the aluminum alloy outer tube I"39 is 58mm, such as image 3 (a) shown.

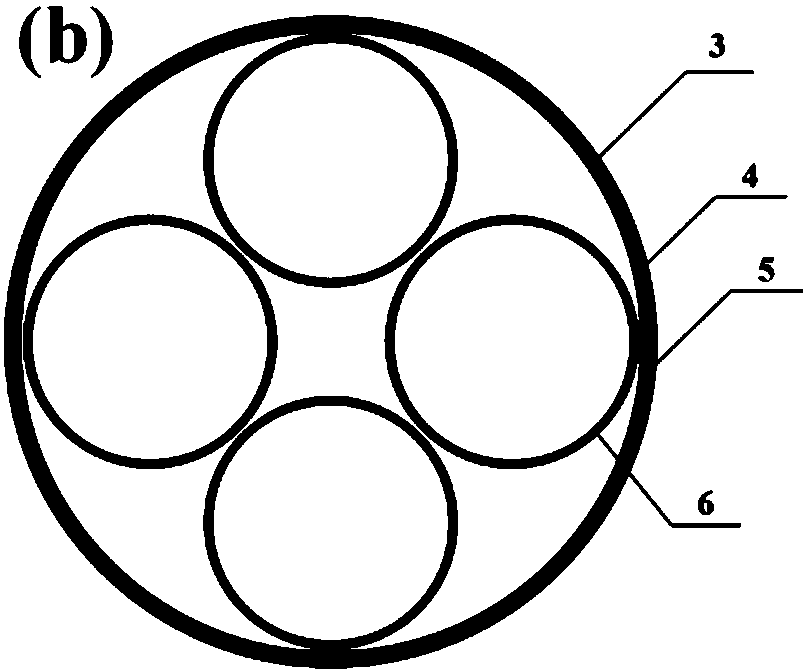

[0055] In plan B, the height II45 of the multicellular structure II44 is 100mm, the number of carbon fiber inner tubes II"47 in the multicellular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com