Oil pressure hand braking control mechanism used for automobile

A control mechanism and hand brake technology, applied in the direction of brakes, manual starting devices, braking action starting devices, etc., can solve the problems of increased cost, short life, and laborious braking of the driver, and achieve simple structure, long life, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

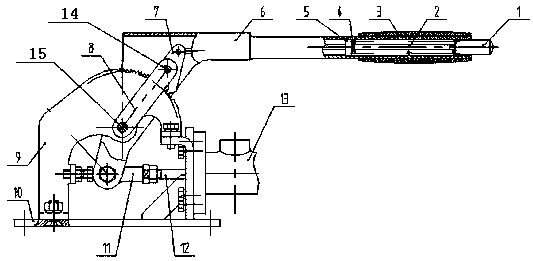

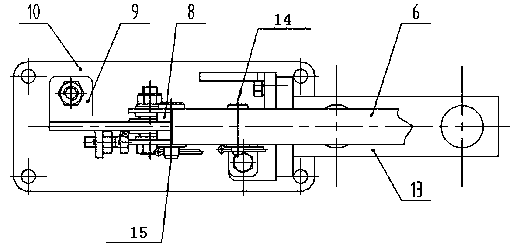

[0014] The present invention is described in conjunction with the accompanying drawings and specific implementation, but does not constitute a limitation to the invention:

[0015] like figure 1 and figure 2 Shown, a kind of oil pressure hand brake control mechanism for automobile, described automobile oil pressure hand brake control mechanism has brake handle 6, and described brake handle 6 has the horizontal bar of horizontal arrangement; The front end of the handle 6 is sleeved, and the handle cover 3 is on the brake handle 6 to play an anti-slip effect; the rear end of the horizontal bar described in the brake handle 6 is inclined downward to form a support rod for the brake handle; The lower end of the support rod is hinged with one end of the centering joint draw ring 11, forming the structure that the brake handle 6 can rotate around the hinge point of the brake handle and the centering joint draw ring under the pull of the hand; The other end of the joint pull ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com