Overturning erecting device and method

A technology in an upper and a horizontal position is applied in the field of devices where large equipment is turned over and erected. It can solve problems such as difficulty in assessing safety, and achieve the effects of offsetting structural deformation, low tolerance accuracy requirements, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

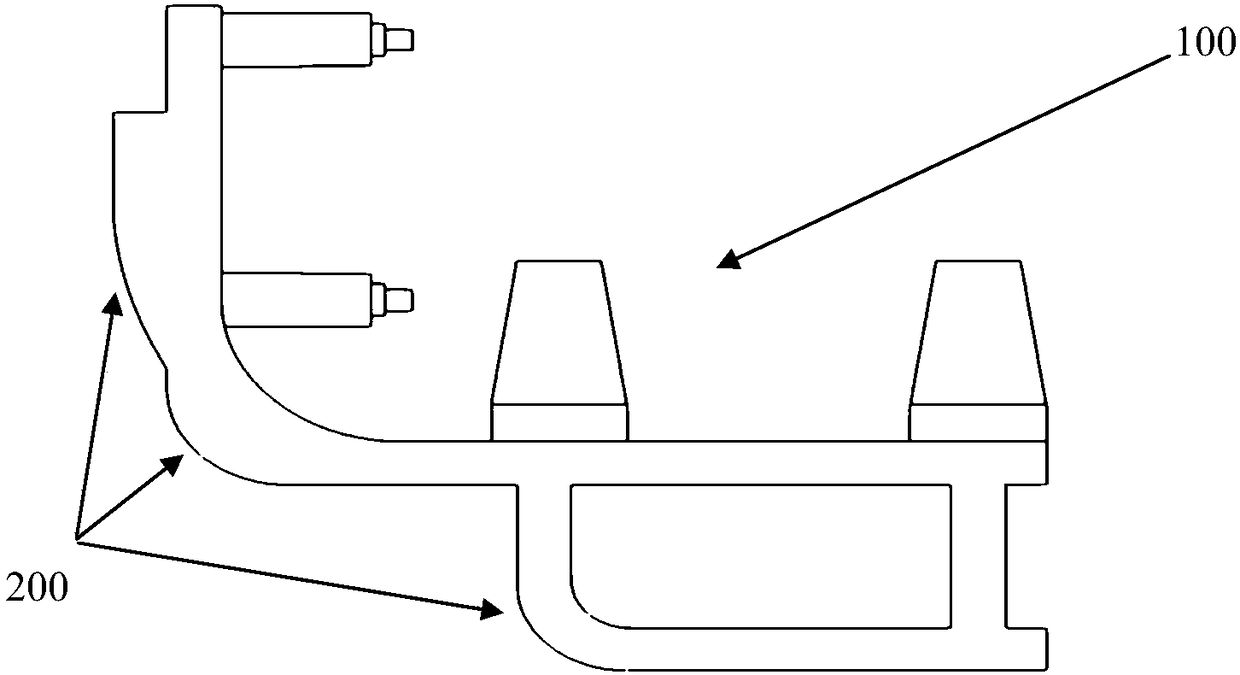

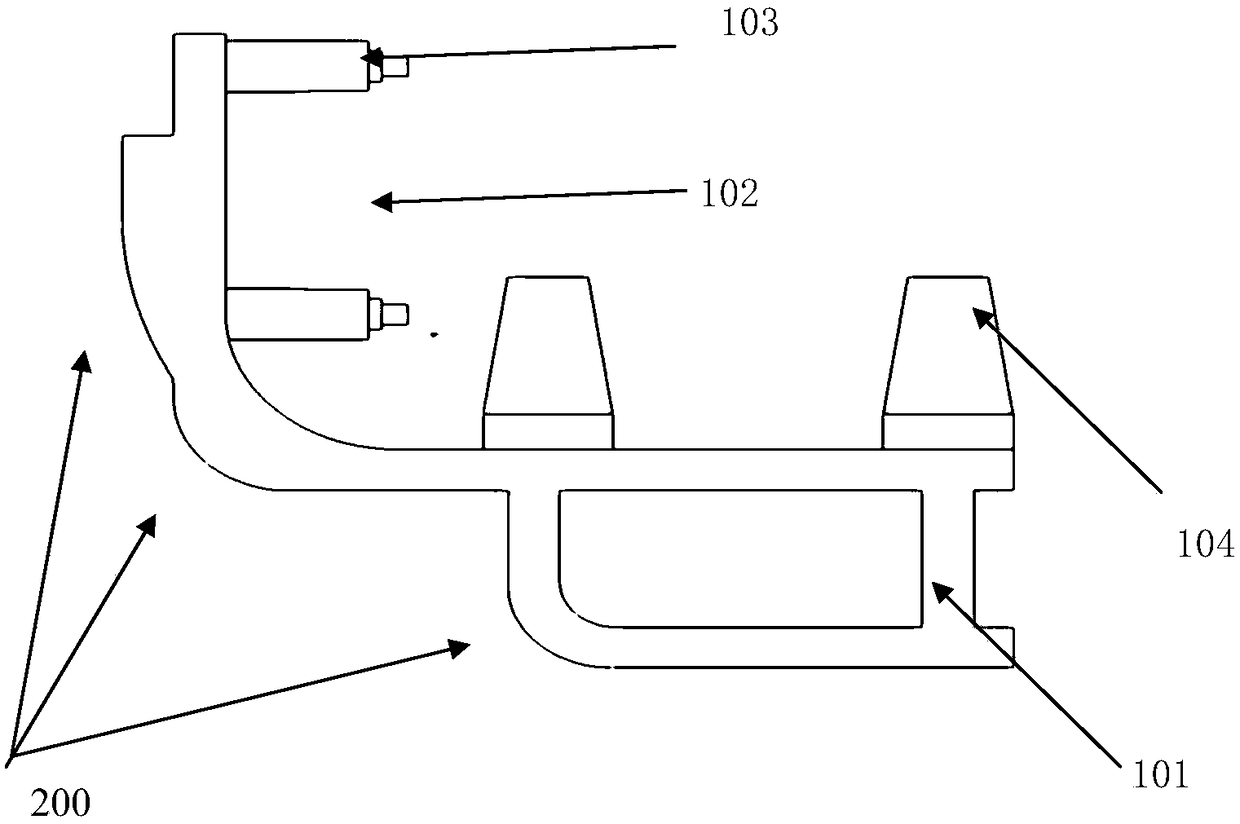

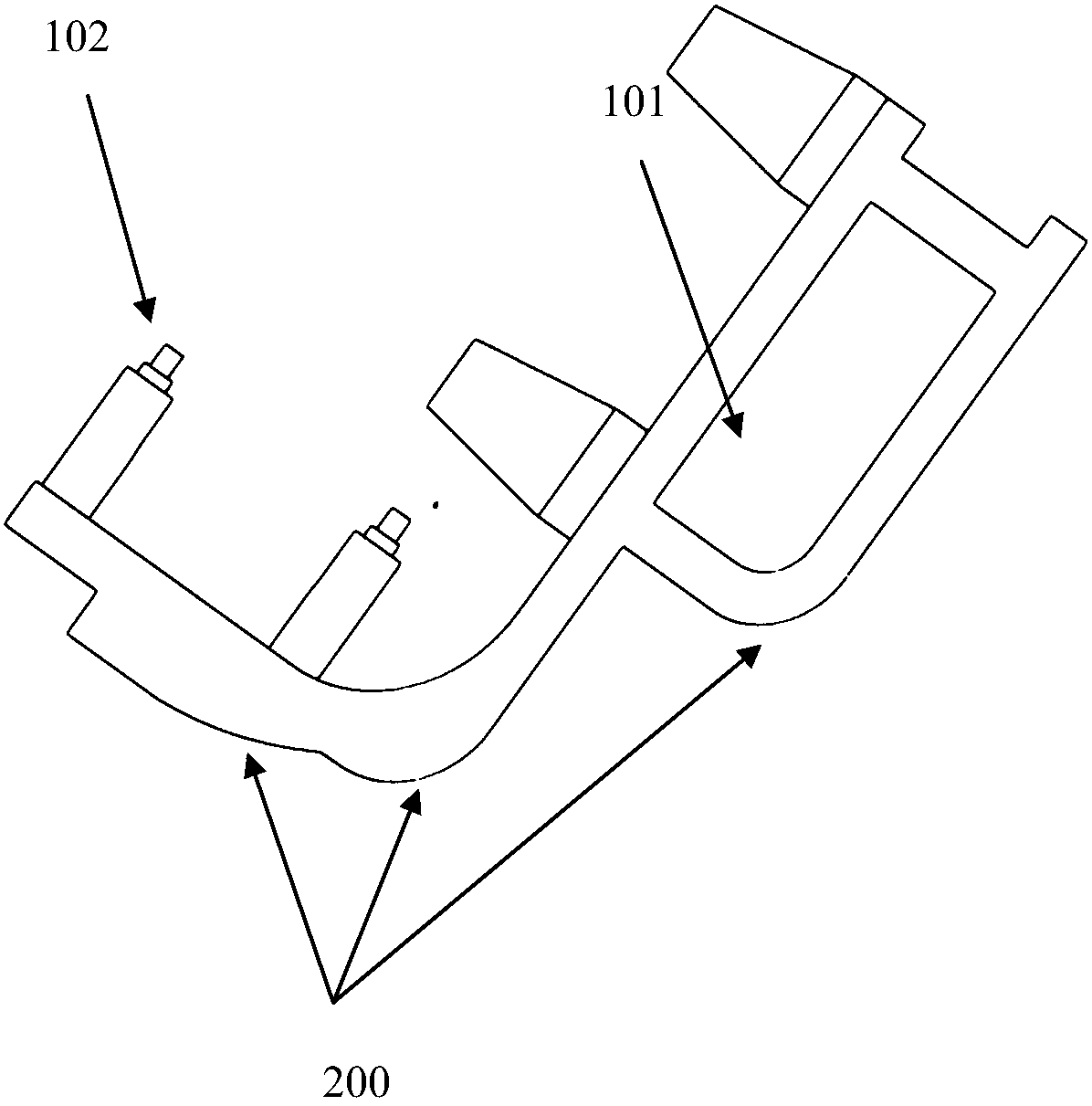

[0062] The turning and erecting of the main system equipment of a nuclear power plant is one of the most important procedures in the installation of a nuclear power plant, and is the main critical path for the construction of a nuclear power plant. Due to the importance and sensitivity of nuclear-grade equipment, the safety of its flipping process has been paid much attention. The invention provides a turning and erecting device for an evaporator, which overcomes the technical prejudice on the spot and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com