A method for preparing high modulus soluble silicate by utilizing gasification slag

A gasification slag and soluble technology, applied in the direction of silicate, alkali metal silicate, aluminum halide, etc., can solve the problems of insignificant economic and environmental benefits, low reactivity of silicon source, high energy consumption and material consumption, etc., to achieve Realize the common development of economic and environmental benefits, significant economic and environmental benefits, and large operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

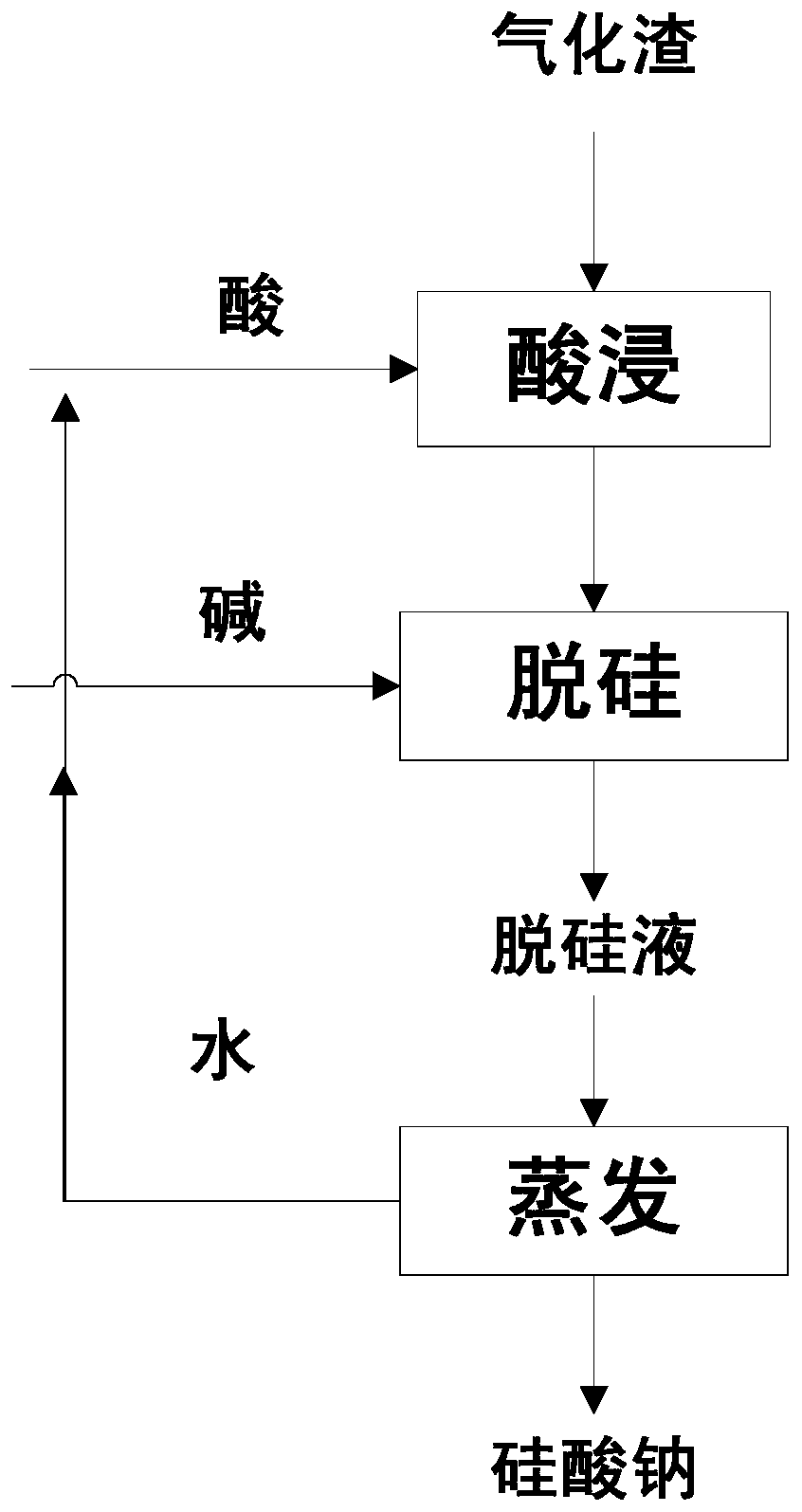

[0072] A kind of technology that utilizes gasification slag to prepare sodium silicate comprises the steps:

[0073] Dissolution process: Gasification slag and industrial by-product hydrochloric acid are used for mixed reaction according to the liquid-solid ratio of 8:1, the concentration of hydrochloric acid is 3mol / L, the reaction temperature is 95°C, the reaction time is 90min, and the rotation speed is 350r / min; the reaction is over Finally, the activated gasification slag is obtained through solid-liquid separation;

[0074] Desiliconization process: react the above activated gasification slag with dilute sodium hydroxide solution, the alkali concentration is 2mol / L, the reaction temperature is 90°C, the reaction time is 120min, the liquid-solid ratio is 5:1, and the rotation speed is 350r / min ; After the reaction finishes, obtain the thick product of sodium silicate through solid-liquid separation;

[0075] Concentration by evaporation: Concentrate the above crude sodiu...

Embodiment 2

[0078] A kind of technology that utilizes gasification slag to prepare sodium silicate comprises the steps:

[0079] Dissolution process: use gasification slag and nitric acid to carry out mixed reaction according to the liquid-solid ratio of 7:1, wherein the concentration of nitric acid is 4mol / L, the reaction temperature is 90°C, the reaction time is 120min, and the rotation speed is 350r / min; after the reaction, after Solid-liquid separation to obtain activated gasification slag;

[0080] Desiliconization process: react the above-mentioned activated gasification slag with dilute sodium hydroxide solution, the alkali concentration is 3mol / L, the reaction temperature is 95°C, the reaction time is 150min, the liquid-solid ratio is 3:1, and the rotation speed is 350r / min ; After the reaction finishes, obtain the thick product of sodium silicate through solid-liquid separation;

[0081] Concentration by evaporation: Concentrate the above crude sodium silicate product to 90% of ...

Embodiment 3

[0084] A kind of technology that utilizes gasification slag to prepare sodium silicate comprises the steps:

[0085]Dissolution process: Gasification slag and industrial by-product hydrochloric acid are used for mixed reaction according to the liquid-solid ratio of 4:1, the concentration of hydrochloric acid is 9mol / L, the reaction temperature is 80°C, the reaction time is 180min, and the rotation speed is 350r / min; the reaction is over Finally, the activated gasification slag is obtained through solid-liquid separation;

[0086] Desiliconization process: react the above activated gasification slag with dilute sodium hydroxide solution, the alkali concentration is 2mol / L, the reaction temperature is 105°C, the reaction time is 120min, the liquid-solid ratio is 5:1, and the rotation speed is 350r / min ; After the reaction finishes, obtain the thick product of sodium silicate through solid-liquid separation;

[0087] Evaporation and concentration: Concentrate the above crude sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com