Preparation method for food-grade potassium chloride

A manufacturing method and technology of potassium chloride, which is applied in the field of potassium salt manufacturing, can solve the problems of low purity of food-grade potassium chloride, and achieve the effects of improving purification purity, increasing solubility, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, a kind of manufacture method of food grade potassium chloride, its steps are as follows:

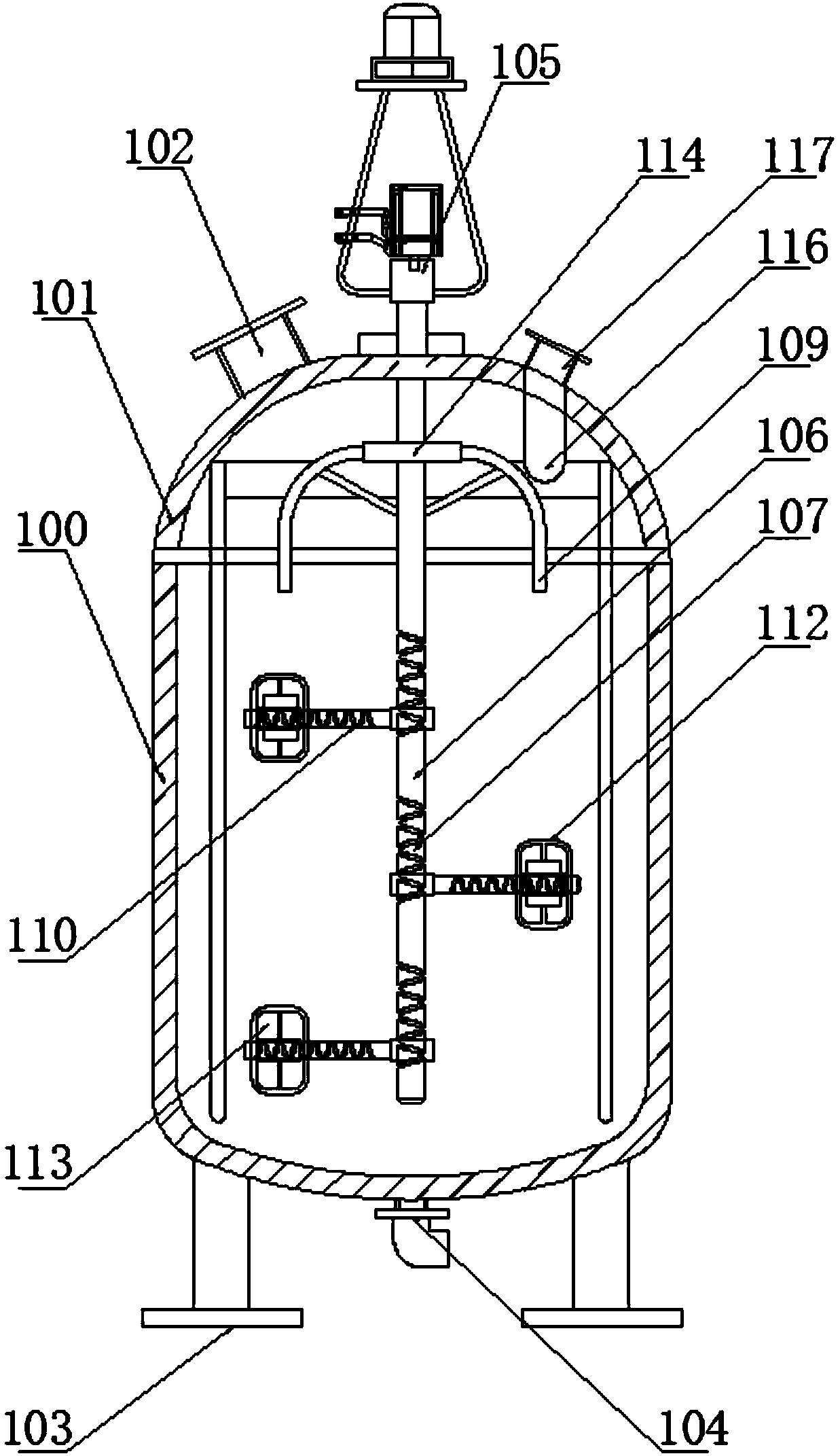

[0046] (1) Dissolution: Under normal pressure, add potassium chloride raw material with a purity of 85% into the dissolution kettle, add pure water or the circulating mother liquor produced during the purification process to dissolve, stir and heat up to 95°C while dissolving, and the stirring speed is at Control at 500r / min until the potassium chloride solution is saturated;

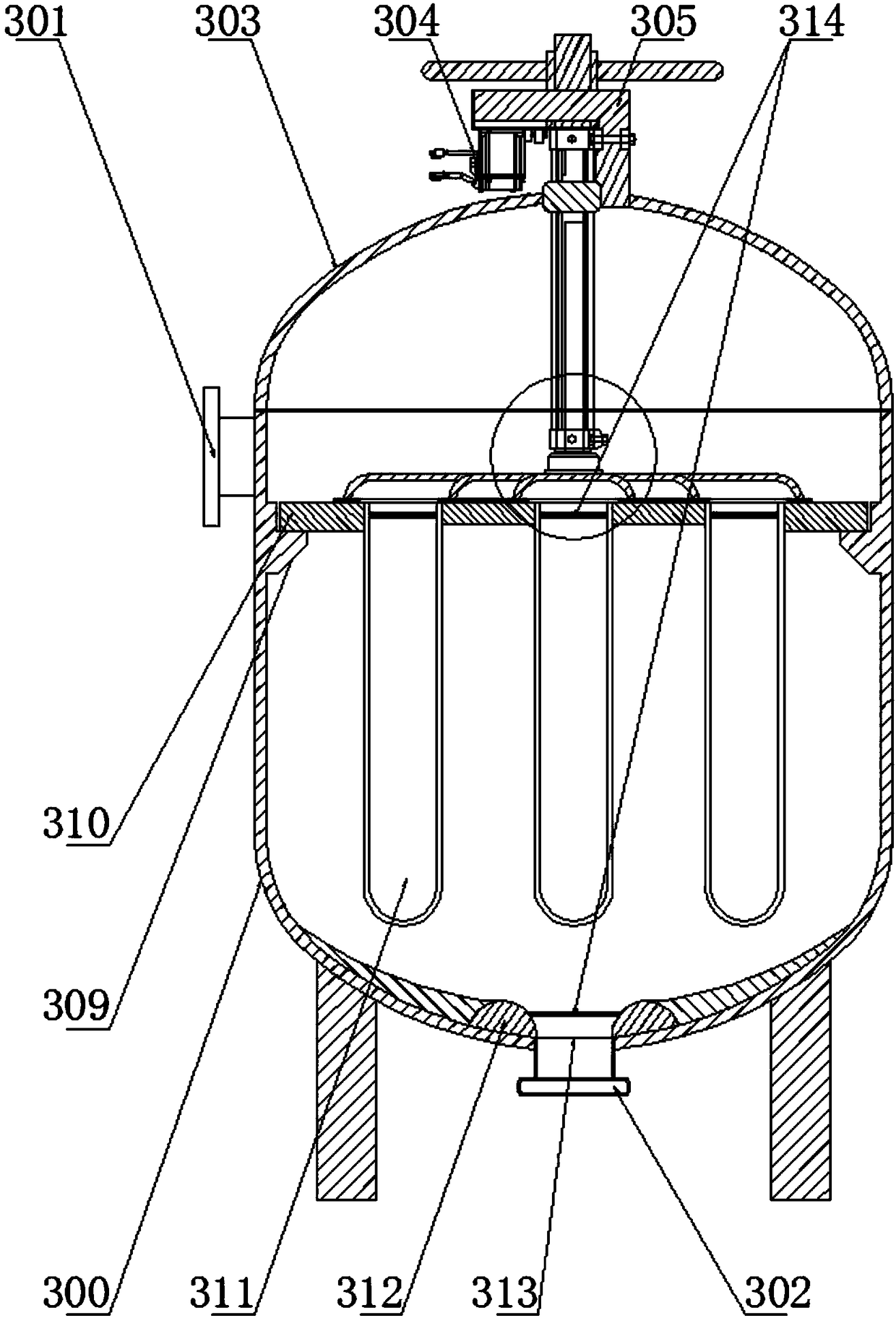

[0047] (2) Pre-filtration: transfer the dissolved potassium chloride saturated solution into the pre-filtration device, the filtration accuracy of the pre-filtration device is not less than 2mm, and obtain the potassium chloride pre-filtration slurry;

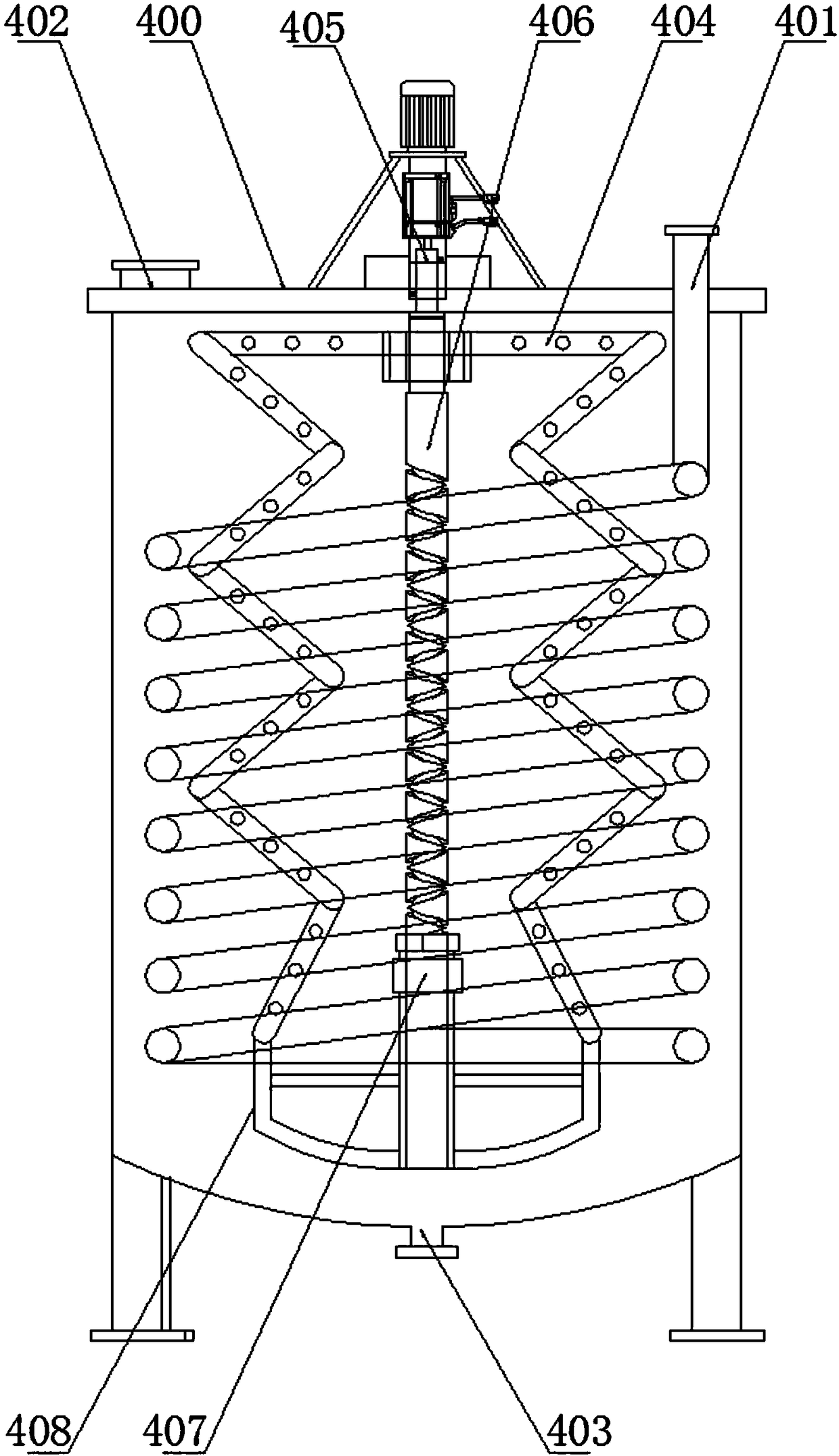

[0048] (3) Fine filtration: The potassium chloride pre-filtered slurry is fine-filtered with a fine-filtration device, the fine-filtration pressure is 0.1kpa, the filtration accuracy is 1μm, and the fine-filtration speed is 7000L per 10 minutes...

Embodiment 2

[0052] Embodiment 2, a kind of manufacture method of food grade potassium chloride, its steps are as follows:

[0053] (1) Dissolution: Under normal pressure, add potassium chloride raw material with a purity of 90% into the dissolution kettle, add pure water or the circulating mother liquor produced during the purification process to dissolve, stir and heat up to 100°C while dissolving, and the stirring speed is at Control at 900 r / min until the potassium chloride solution is saturated;

[0054] (2) Pre-filtration: transfer the dissolved potassium chloride saturated solution into the pre-filtration device, the filtration accuracy of the pre-filtration device is not less than 2mm, and obtain the potassium chloride pre-filtration slurry;

[0055] (3) Fine filtration: the potassium chloride pre-filtered slurry is fine-filtered with a fine-filtration device, the fine-filtration pressure is 0.2kpa, the filtration accuracy is 1μm, and the fine-filtration speed is 7000L per 15 minut...

Embodiment 3

[0059] Embodiment 3, a kind of manufacture method of food grade potassium chloride, its steps are as follows:

[0060] (1) Dissolution: Under normal pressure, add potassium chloride raw material with a purity of 90% into the dissolution kettle, add pure water or the circulating mother liquor produced during the purification process to dissolve, stir and heat up to 100°C while dissolving, and the stirring speed is at Control at 700 r / min until the potassium chloride solution is saturated;

[0061] (2) Pre-filtration: transfer the dissolved potassium chloride saturated solution into the pre-filtration device, the filtration accuracy of the pre-filtration device is not less than 2mm, and obtain the potassium chloride pre-filtration slurry;

[0062] (3) Fine filtration: The potassium chloride pre-filtered slurry is fine-filtered with a fine-filtration device, the fine-filtration pressure is 0.15kpa, the filtration accuracy is 1μm, and the fine-filtration speed is 7000L per 15 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com