Launching oil-water separator

An oil-water separator and oil-collecting technology, applied in the direction of liquid separation, separation method, grease/oily substance/floating matter removal device, etc., can solve problems such as difficult to achieve normal oil-water drop, difficult oil-water separation, etc., to achieve decontamination and oil removal Ideal effect, low production cost, and easy daily cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

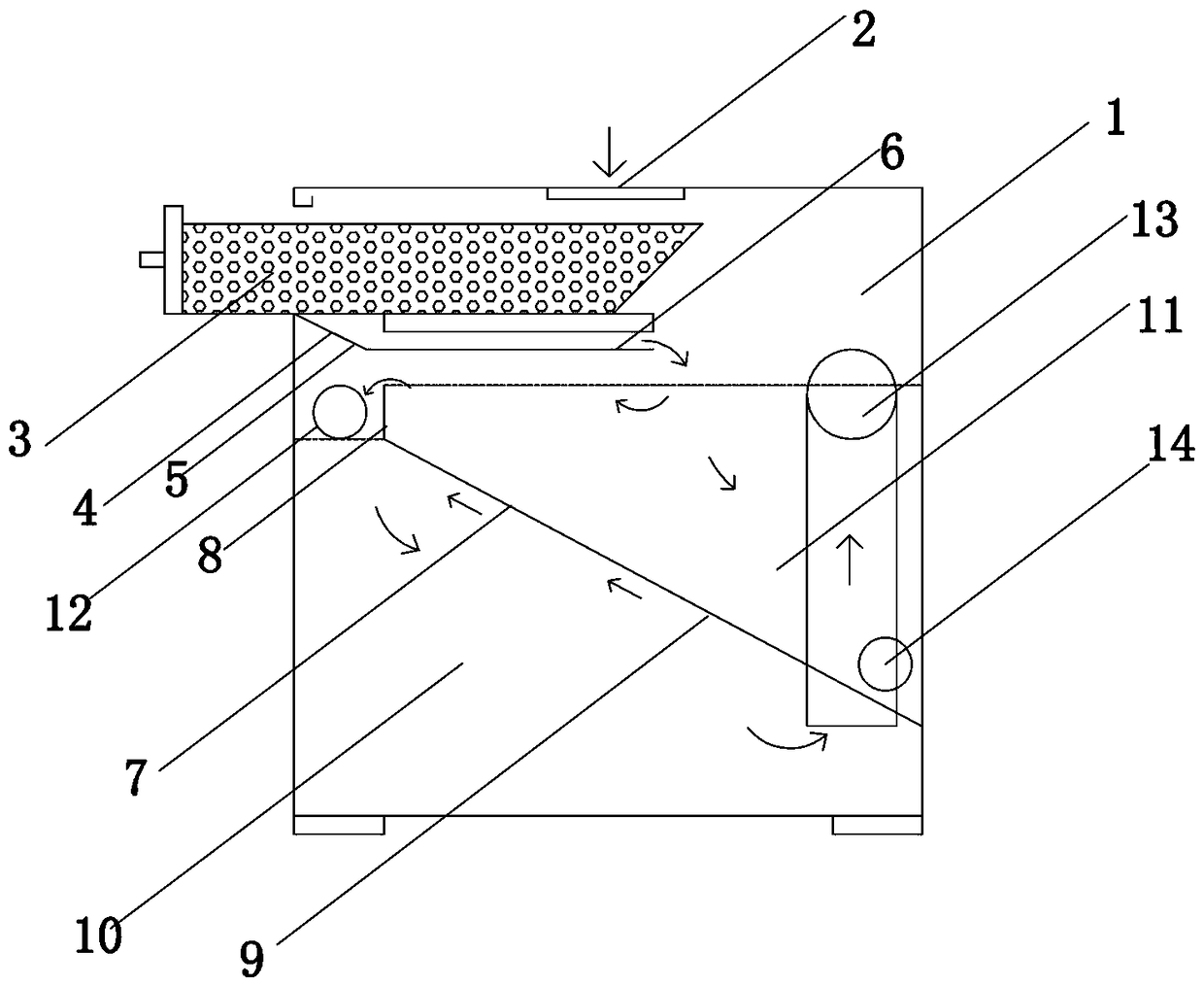

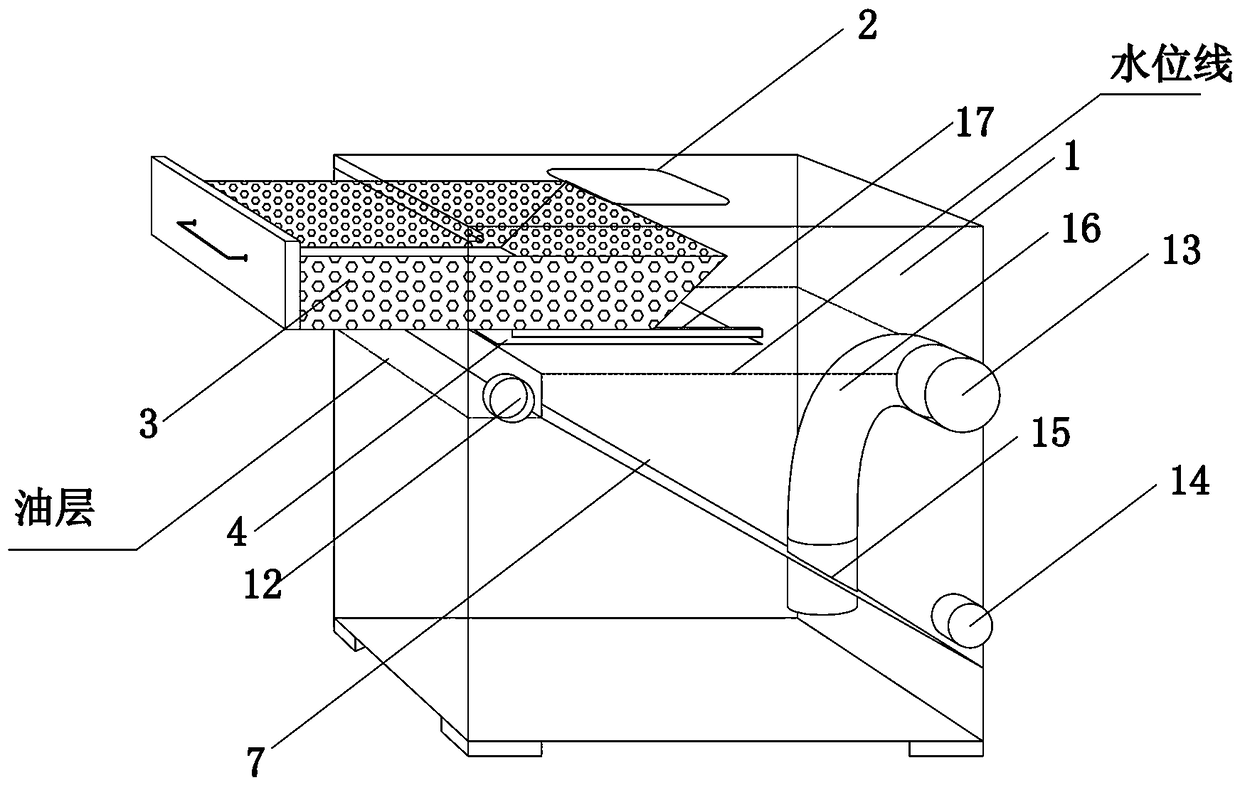

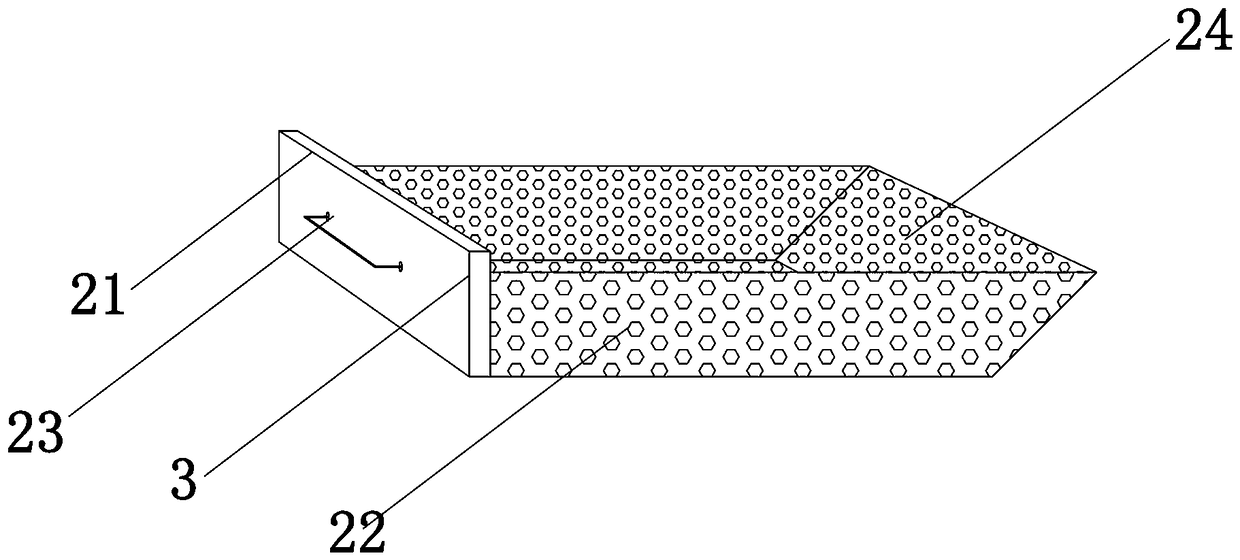

[0023] Such as Figure 1-3 As shown, the sewer type oil-water separator provided in this embodiment includes a frame body 1, the top wall of the frame body 1 is provided with a water inlet 2, and a drawer type filter residue device 3 is arranged below the water inlet 2, and the drawer Type filter residue device 3 is located on the front side of the frame body 1, and a water distribution plate 4 is provided below the drawer type filter residue device 3. The water distribution plate 4 is composed of an integrally formed drainage plate 5 and a horizontal plate 6, wherein the drainage plate 5 It is obliquely fixed on the side of the frame body 1, and an oil baffle 7 is provided under the water distribution plate 4, and the oil baffle 7 is composed of an integrally formed vertical plate 8 and an inclined plate 9, wherein the vertical plate 8 is located on the inclined plate 9, the oil baffle plate 7 divides the water holding area of the frame body 1 into a first chamber 10 and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com