A cyclic heat treatment method for improving the paint performance of aluminum alloy automotive panels

A heat treatment method and technology for automobile sheets, applied in the field of aluminum alloy automobile sheet processing technology, can solve the problems of lack of exploration and research on the performance of baking paint, and achieve the effect of inhibiting the negative effect of natural aging and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

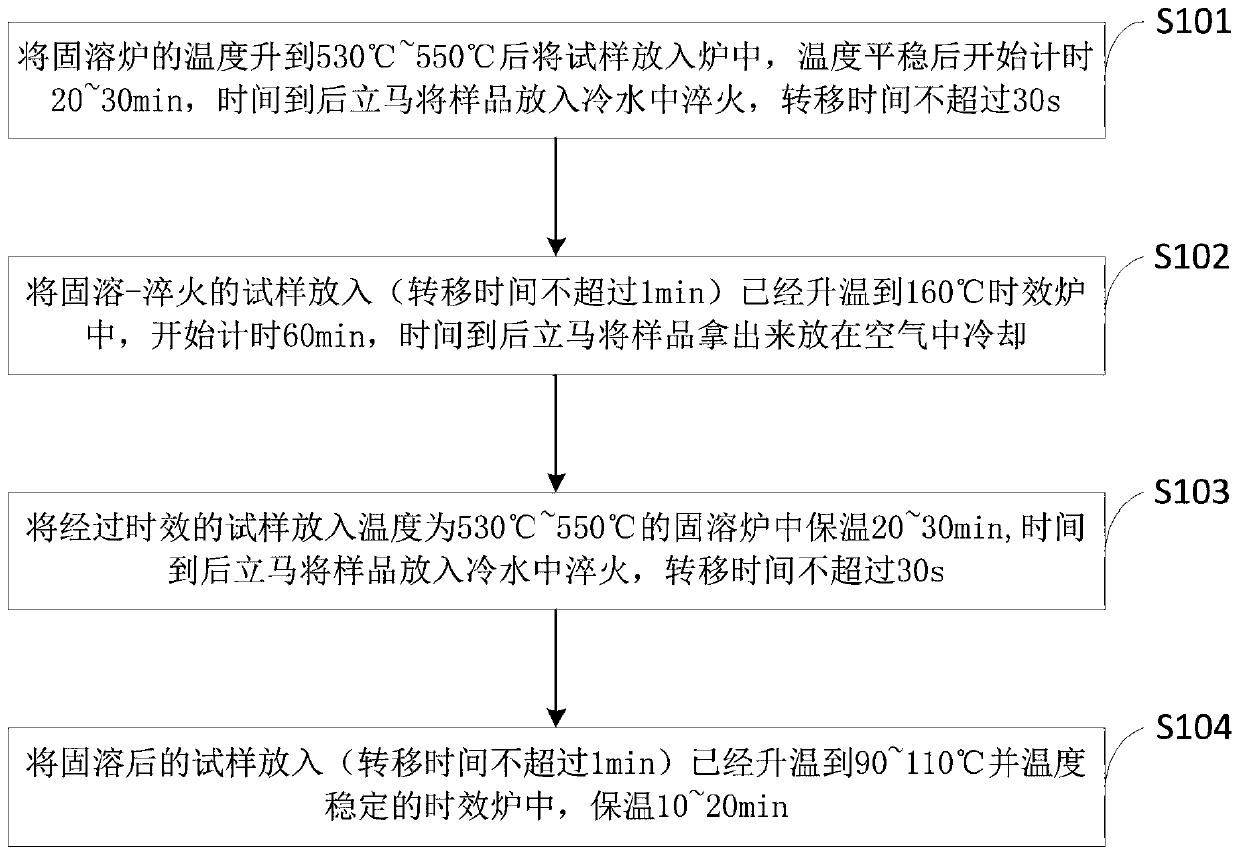

Method used

Image

Examples

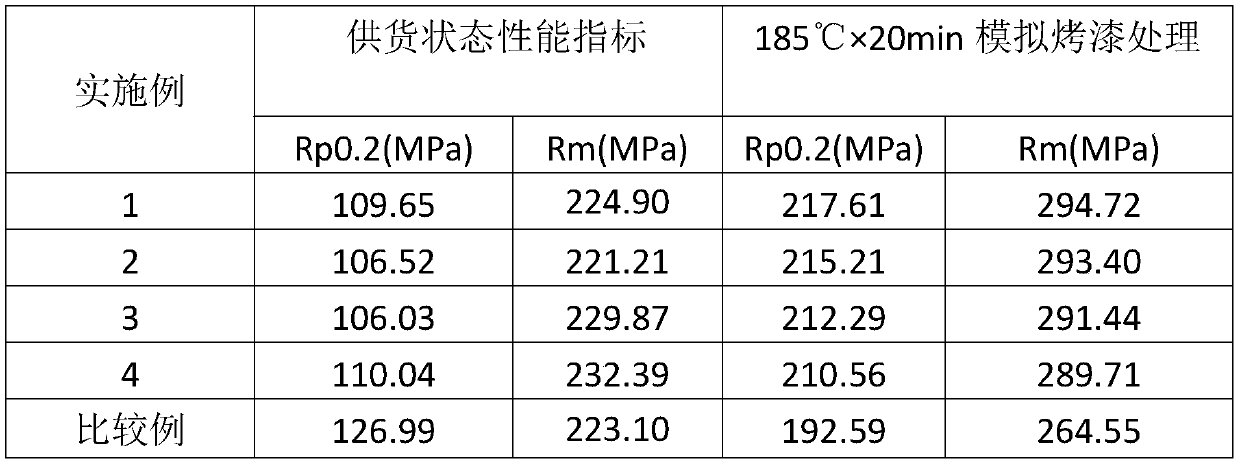

Embodiment 1

[0024] 550℃×20min solution treatment→160℃×60min pre-aging→550℃×20min solution treatment→110℃×10min pre-aging→storage at room temperature for 14 days→tensile test→185℃×20min simulated baking paint treatment;

Embodiment 2

[0026] 540℃×25min solution treatment→180℃×40min pre-aging→540℃×25min solution treatment→110℃×10min pre-aging→storage at room temperature for 14 days→tensile test→185℃×20min simulated baking paint treatment;

example 3

[0028] 530℃×30min solution treatment→160℃×60min pre-aging→530℃×30min solution treatment→90℃×20min pre-aging→storage at room temperature for 14 days→tensile test→185℃×20min simulated baking paint treatment;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com