Intelligent electronically controlled drainage method and device for steam drying cylinders

A steam dryer and hydrophobic technology, applied in the removal of liquid/gas/steam, textiles and papermaking, textile material treatment, etc., can solve the problems of increasing production and operating costs, increasing steam consumption, and easy accumulation of water in the drying cylinder. Achieve the effects of high hydrophobic measurement and control accuracy, improve steam utilization rate, and improve hydrophobic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

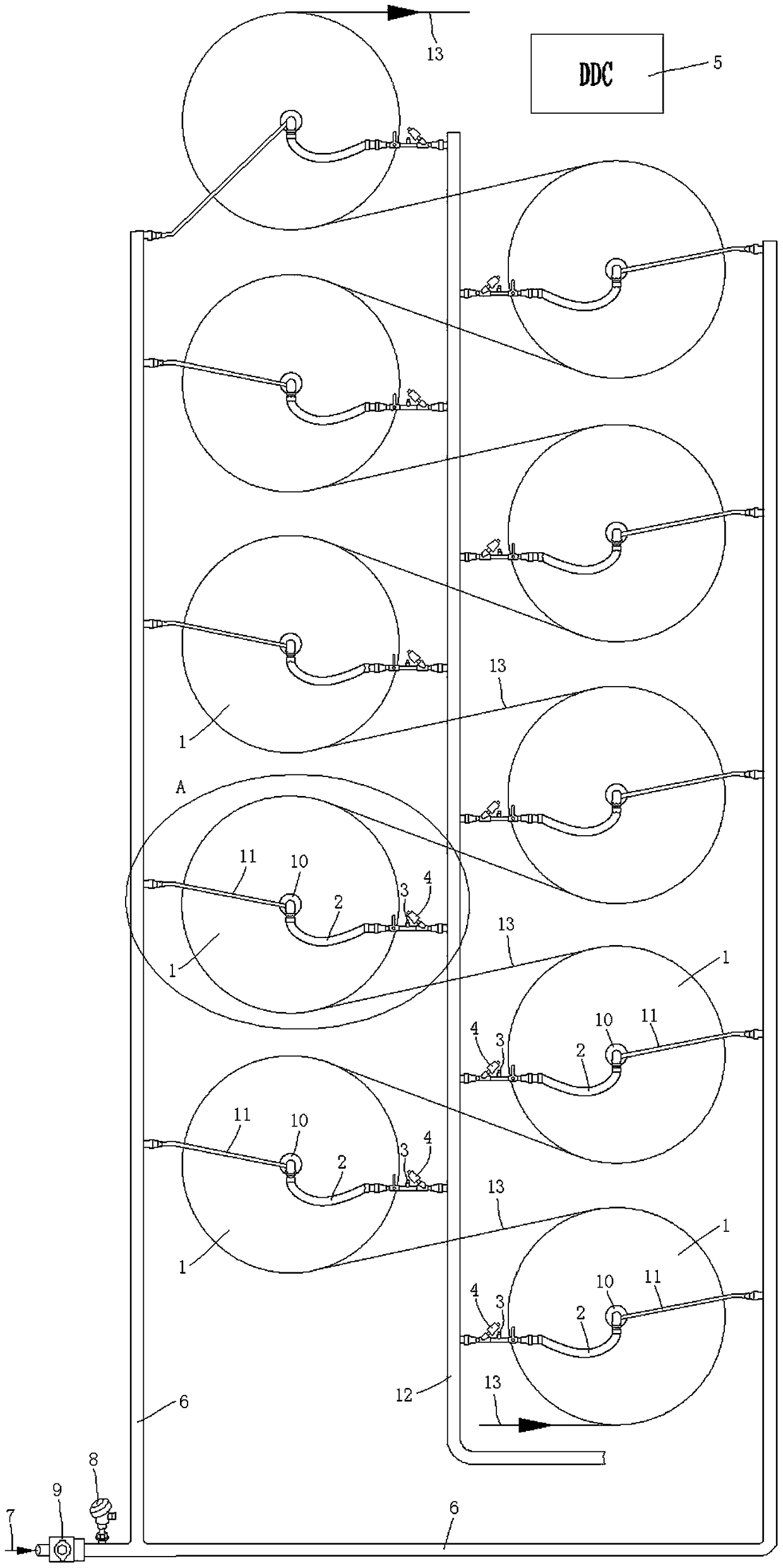

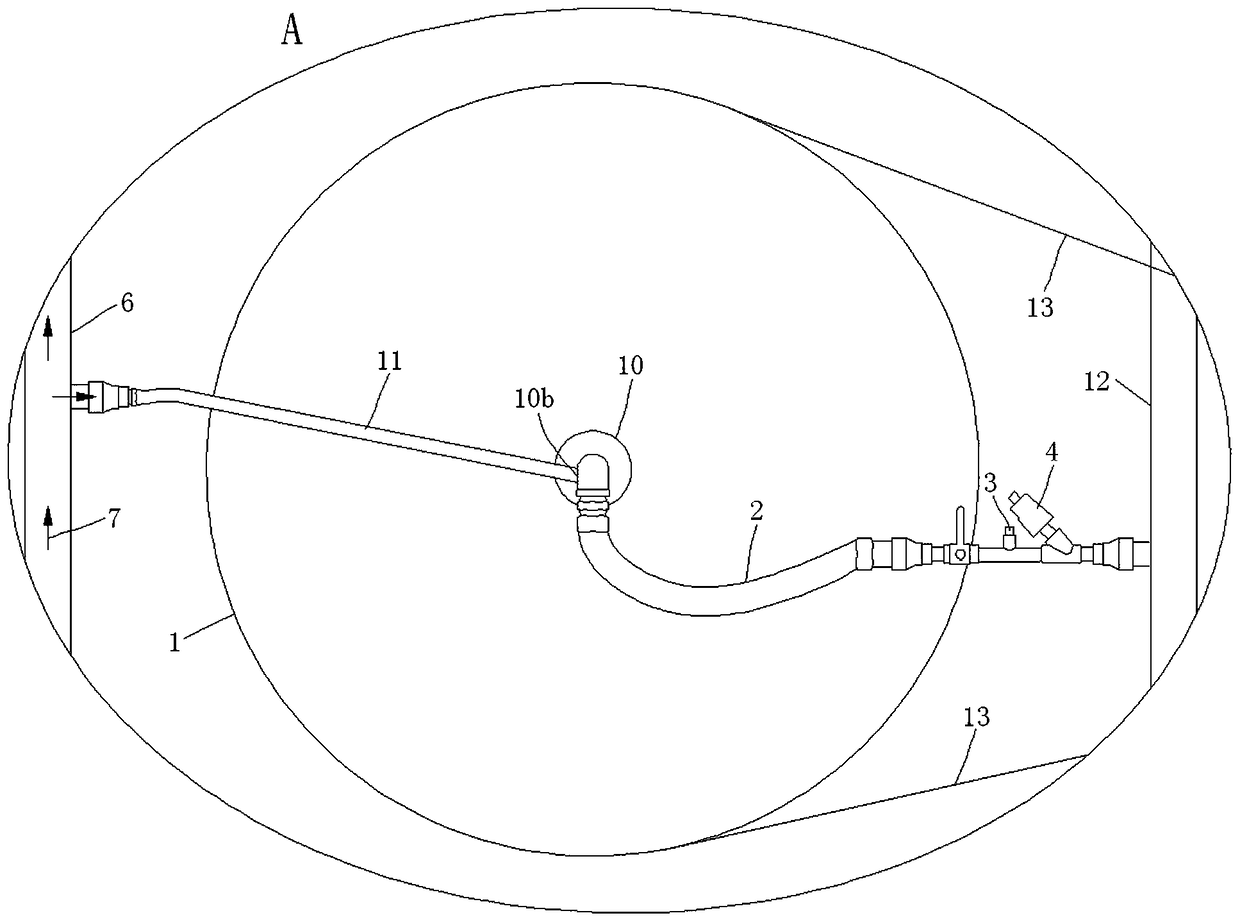

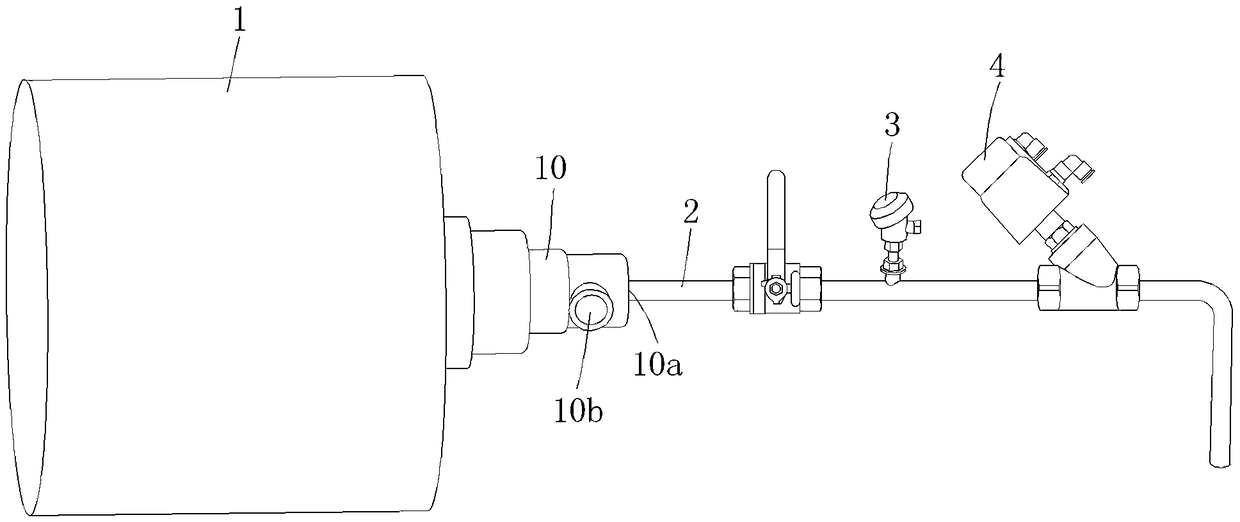

[0025] See Figure 1 to Figure 3 Shown is an intelligent electronically controlled drainage method for steam drying drums. The method uses steam 7 to be fed into the steam drying drum 1 through the steam main pipe 6, and the condensed water in the steam drying drum 1 is pushed out through the drain pipe 2 and the control valve 4 When the temperature in the pipe of the drain pipe 2 is equal to the product of the steam temperature in the steam main pipe 6 and the temperature coefficient K plus the return difference temperature △T is true, the control valve 4 is closed to stop the drain; When the temperature in the circuit is equal to the product of the steam temperature in the steam manifold 6 and the temperature coefficient K, the control valve 4 is opened to perform drainage; where 0°C<△T≤6°C, 0.6≤K≤0.9.

[0026] As a preferred embodiment of the above method, the value range of the hysteresis temperature ΔT is 2 to 5° C., and the value range of the temperature coefficient K is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com