Railway track rubber shock absorbing structure and rubber

A technology of rubber shock absorption and railway track, which is applied in the rubber shock absorption structure of railway track and rubber field, which can solve the problems of uneven levelness of railway sleepers and unsatisfactory use effects, and achieve the effect of slowing down multi-dimensional vibration and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

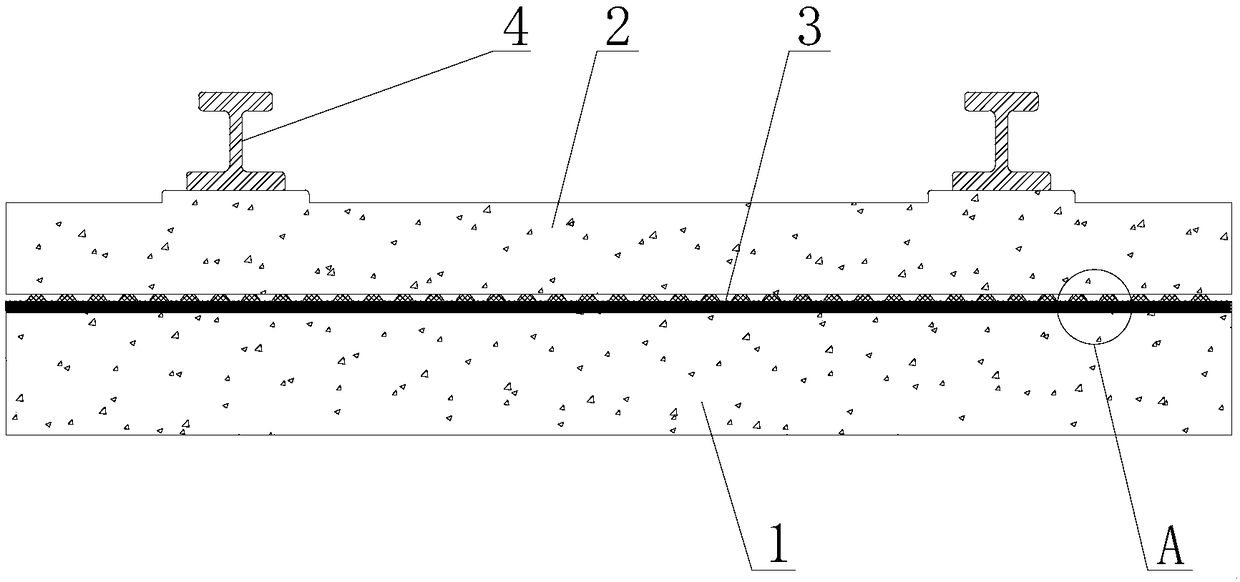

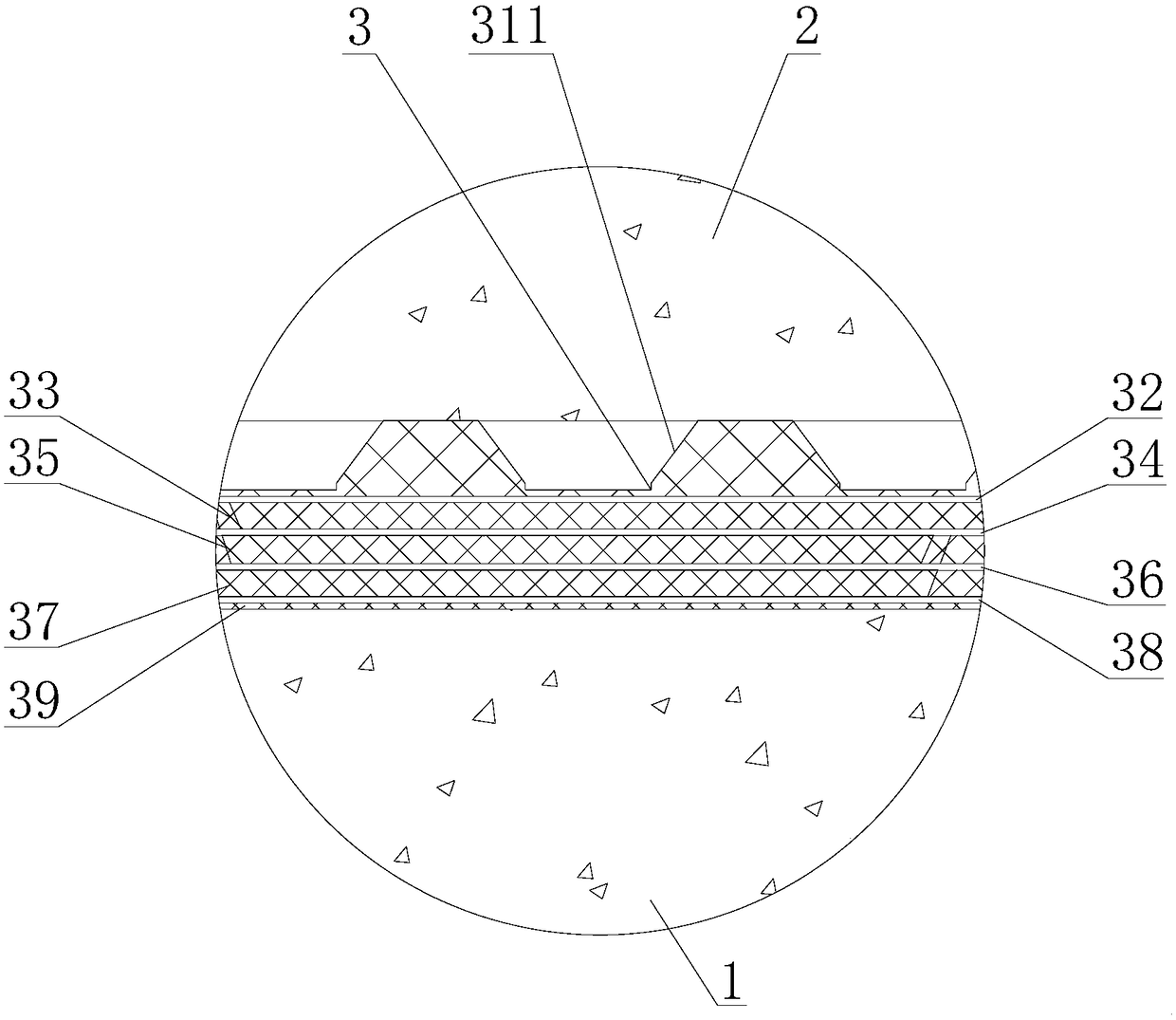

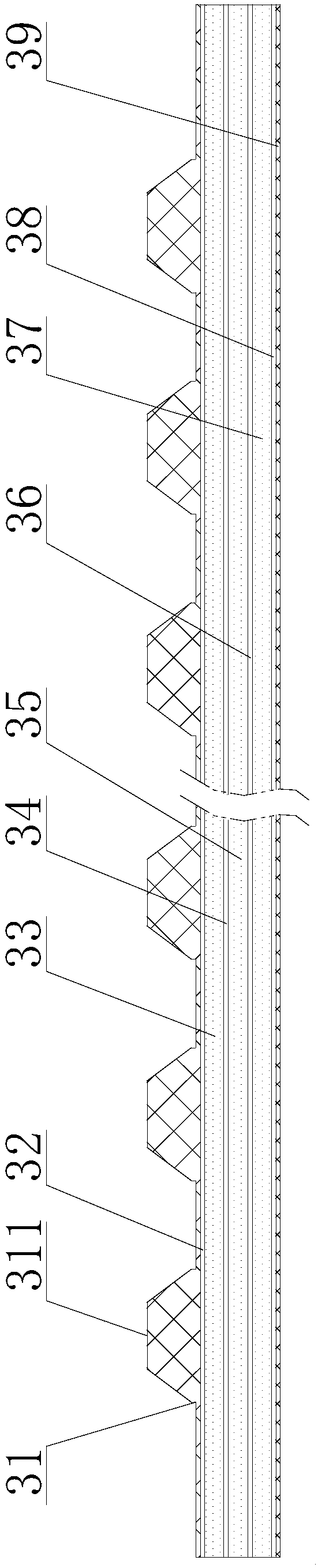

[0023] see figure 1 , figure 2 , image 3 and Figure 4 , the railway track rubber damping structure, including a cement base 1 and a prefabricated sleeper rail component 2 above the cement base 1, and a rubber damping rubber damper located between the cement base 1 and the sleeper rail prefabricated component 2 Shock pad 3; the rubber shock pad 3 from top to bottom is a trapezoidal rubber balance buffer layer 31, a first fiber support net 32, a first pressure-bearing rigid damping core rubber layer 33, a second fiber support net 34, and a second fiber support net 34. Two pressure-bearing rigid damping core rubber layers 35, the third fiber support network 36, the third pressure-bearing rigid damping core rubber layer 37, the fourth fiber support network 38 and the grid skeleton bonding layer 39, each layer is bonded by vulcanization A group of trapezoidal strips 311 are uniformly arranged on the trapezoidal rubber balance buffer layer 31 .

[0024] The material formula o...

Embodiment 2

[0031] Different from Example 1, in Example 2, the material formula of the trapezoidal rubber balance buffer layer 31 is calculated in parts by weight: 30 parts of trans polyisoprene, 40 parts of chlorosulfonated polyethylene, high cis 30 parts of formula butadiene, 2 parts of magnesium oxide, 3 parts of anti-aging agent, 2 parts of accelerator, 1.5 parts of stearic acid, 22 parts of carbon black N330, 28 parts of carbon black N770, 10 parts of carbon black N990, 12 parts of softener , 4 parts of zinc oxide, 2.6 parts of lead oxide and 1.2 parts of vulcanizing agent.

[0032] The material formulations of the first pressure-bearing rigid damping core rubber layer 33, the second pressure-bearing rigid damping core rubber layer 35 and the third pressure-bearing rigid damping core rubber layer 37 are by weight: trans polyisoprene 20 parts, 50 parts of chlorosulfonated polyethylene, 30 parts of high cis-butadiene, 4 parts of magnesium oxide, 3 parts of anti-aging agent, 2.2 parts o...

Embodiment 3

[0035] The difference from Example 1 is that in Example 3, the material formula of the trapezoidal rubber balance buffer layer 31 is calculated in parts by weight: 30 parts of trans polyisoprene, 70 parts of chlorosulfonated polyethylene, high cis 30 parts of formula butadiene, 6 parts of magnesium oxide, 5 parts of anti-aging agent, 5 parts of accelerator, 3 parts of stearic acid, 50 parts of carbon black N330, 50 parts of carbon black N770, 50 parts of carbon black N990, 15 parts of softener , 10 parts of zinc oxide, 5 parts of lead oxide and 3 parts of vulcanizing agent.

[0036] The material formulations of the first pressure-bearing rigid damping core rubber layer 33, the second pressure-bearing rigid damping core rubber layer 35 and the third pressure-bearing rigid damping core rubber layer 37 are by weight: trans polyisoprene 20 parts, 50 parts of chlorosulfonated polyethylene, 60 parts of high cis-butadiene, 6 parts of magnesium oxide, 5 parts of anti-aging agent, 5 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com