Insulation wall in prefabricated building precast reinforced concrete and inner and outer wall plate connecting rebar

A technology for thermal insulation walls and reinforced concrete, applied in thermal insulation, construction, building components, etc., can solve problems such as lowering the quality of life, easy damp on walls, and discomfort in life, and achieve improved safety performance, reduced transportation difficulty, and braking effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

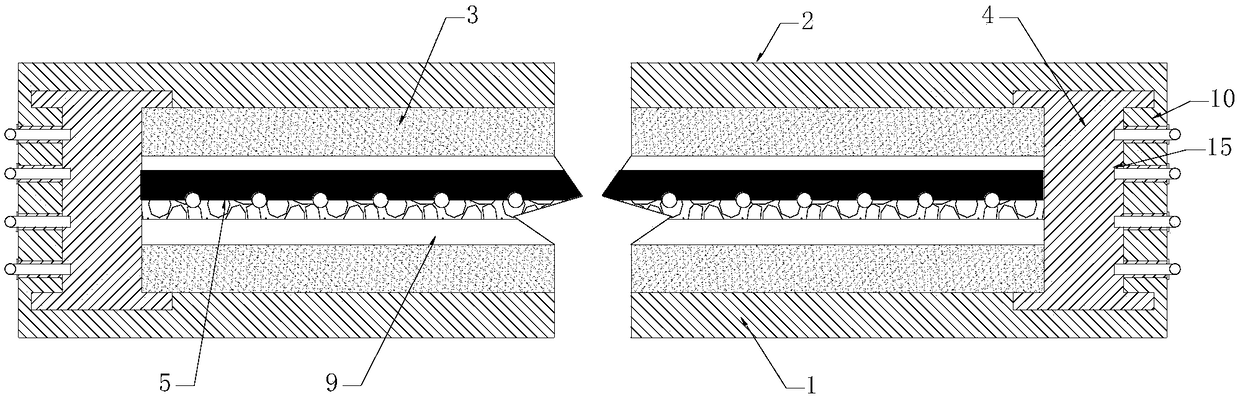

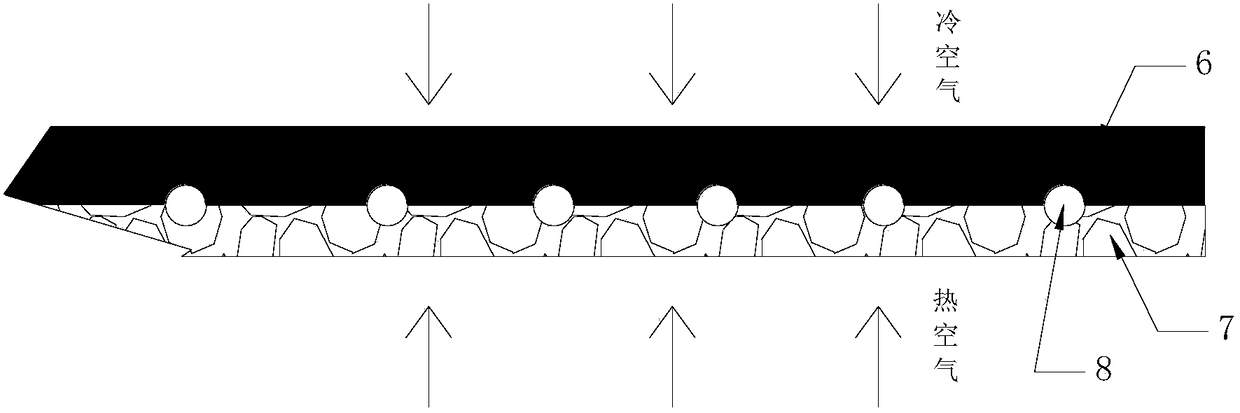

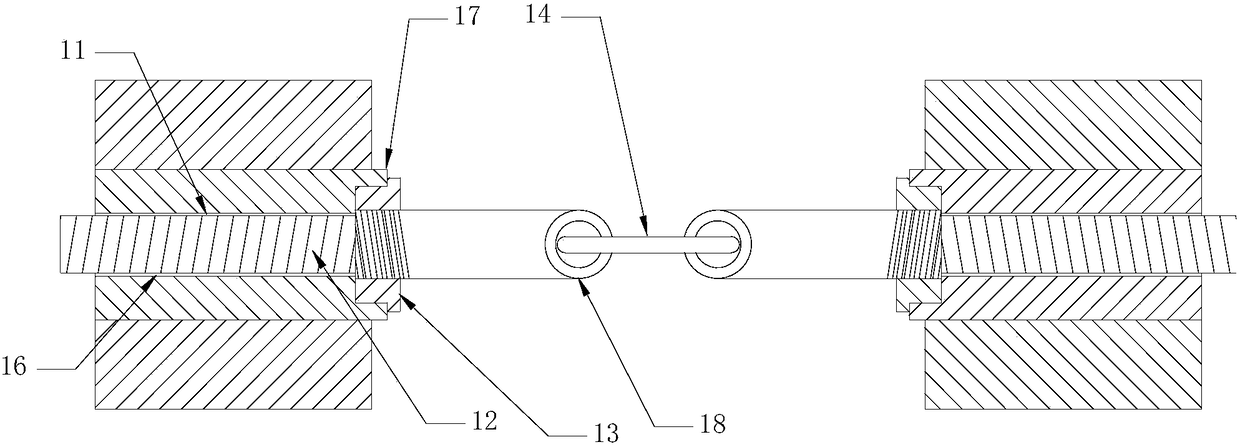

[0019] Please refer to the accompanying drawings, a prefabricated reinforced concrete inner thermal insulation wall for prefabricated buildings, including outer wall 1, inner wall 2, heat insulation material 3, I-beam 4 and cooling plate 5, the inner and outer walls are both It is a cement plate, and the I-beam 4 is sandwiched between the inner and outer walls. The inner wall 1 and the outer wall 2 are fixedly installed with a heat insulating material 3, and the cooling plate 5 includes a thermally benign conductor material. The cooling plate 6 made and the partition plate 7 made of thermal poor conductor material, the partition plate 7 is combined with the cooling plate 6, and a groove 8 with a semicircular cross section is provided on the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com