Underdrain-type tunnel after-lining drainage repairing system and construction method thereof

A technology for repairing systems and culverts, applied in drainage, earthwork drilling, safety devices, etc., to achieve the best drainage effect, prevent blockage, and increase the drainage capacity of the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

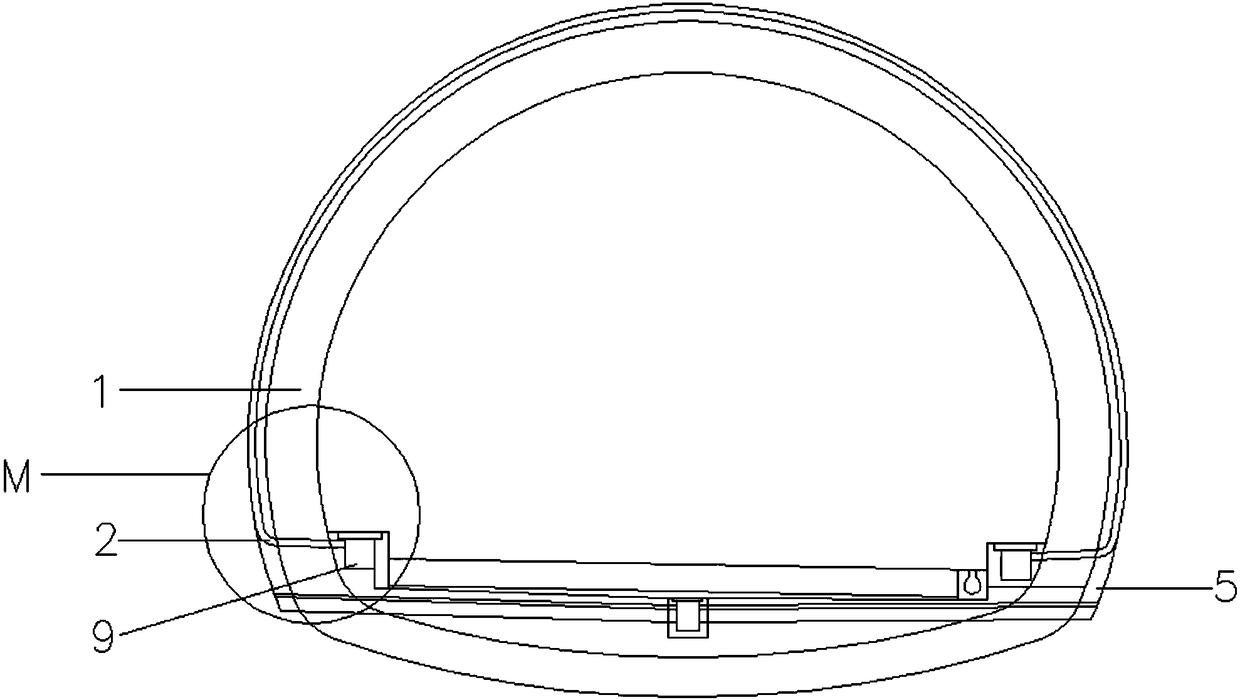

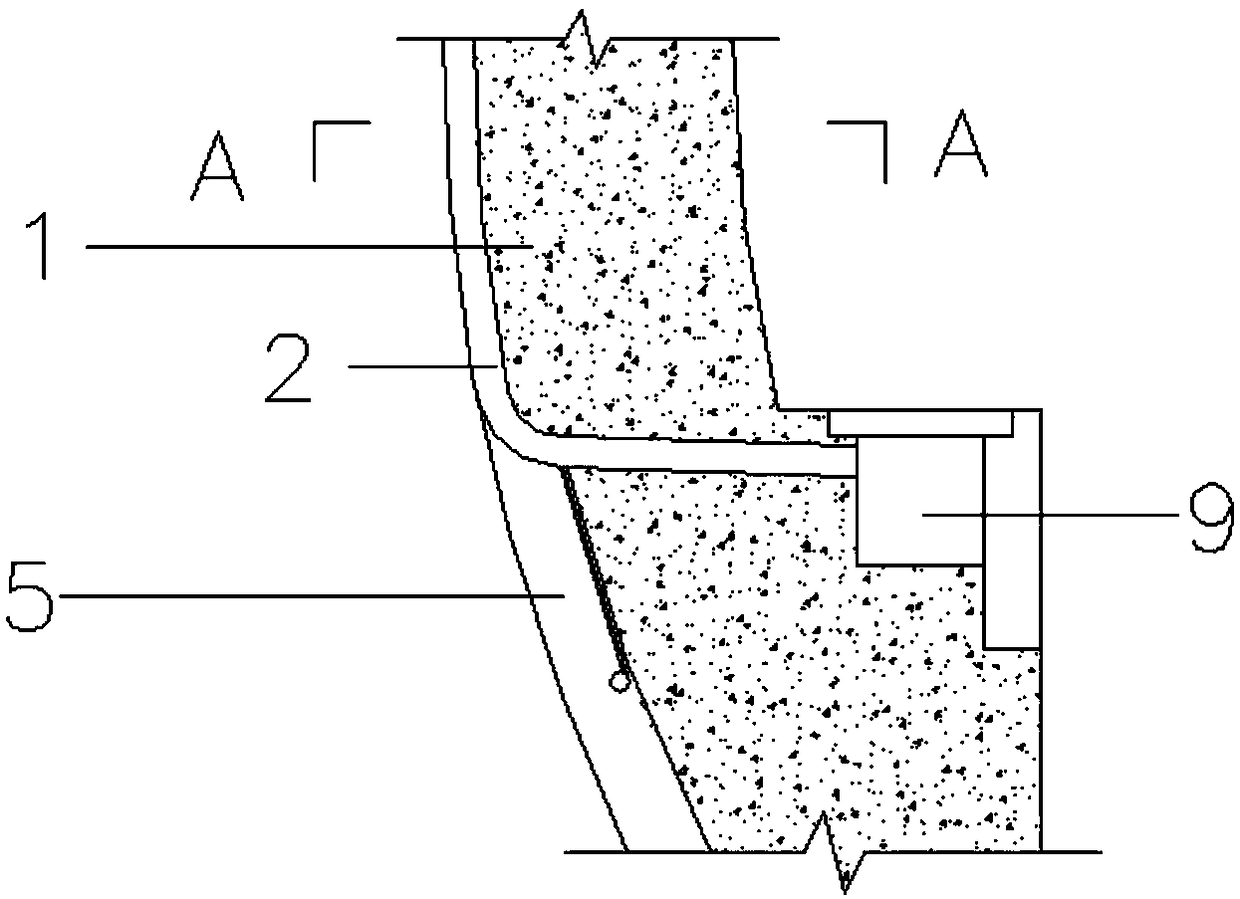

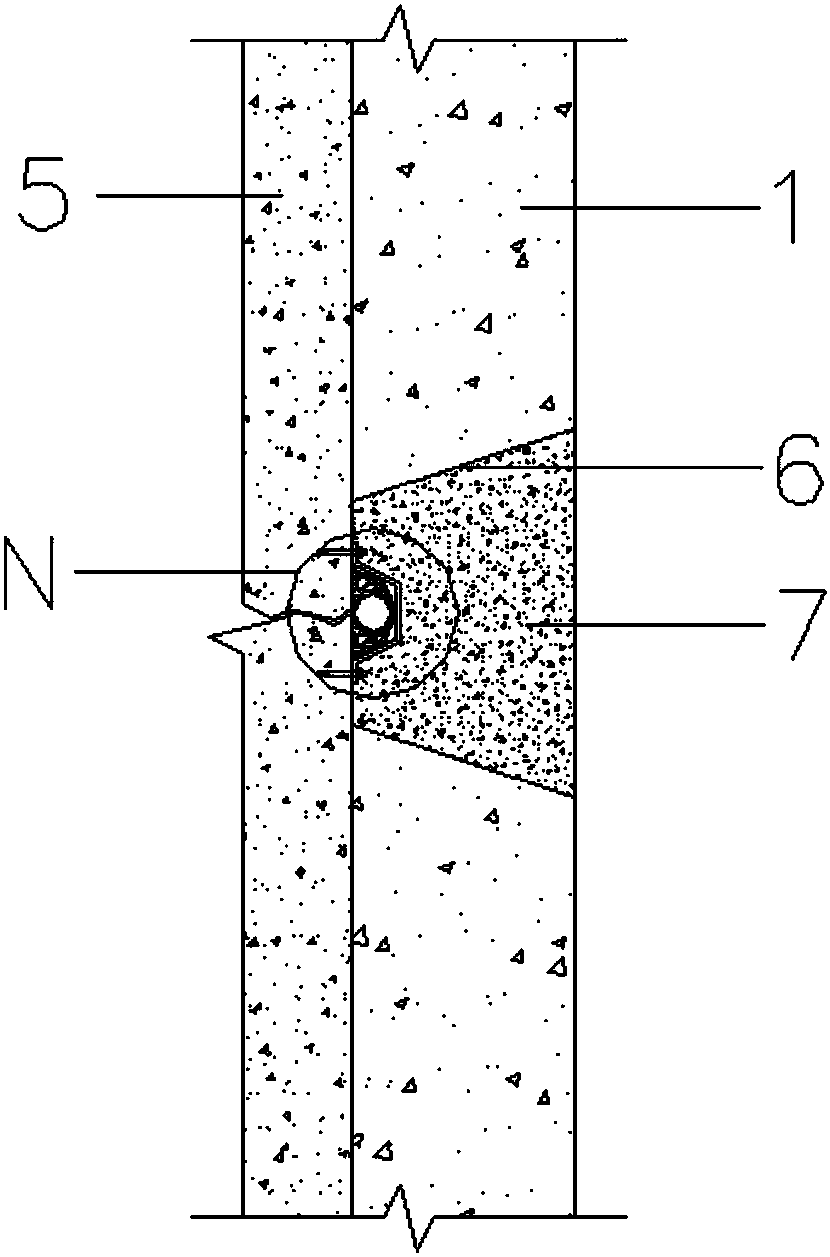

[0031] Such as Figure 1~4 , a subterranean tunnel lining drainage repair system, comprising a half-section pipe 2 circumferentially arranged at the water leakage joint 11 of the secondary lining 1; the opening side of the half-section pipe 2 passes through a clamp 4 with an expansion bolt 3 fixedly attached to the initial support 5; the secondary lining 1 is excavated with a gap 6 on the side away from the opening of the half-cut pipe 2; the gap 6 is filled with high-strength polymer waterproof mortar 7; the half-cut pipe 2 There is a soft permeable pipe or geotechnical blind ditch 8 inside, and the two ends of the half-cut pipe 2 are connected to the side ditch or the central ditch 9; Filled with water permeable filler 10.

[0032] Specifically, when there is cracking and water seepage after the lining of the tunnel, the water flows fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com